Gearbox with 2+1 gears for electric automobile

A technology for electric vehicles and gearboxes, applied in vehicle gearboxes, transmission components, transmission devices, etc., can solve problems such as inconvenient assembly and maintenance, and achieve the goal of improving overall dynamic performance, reducing tooth surface meshing noise, and improving fatigue life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

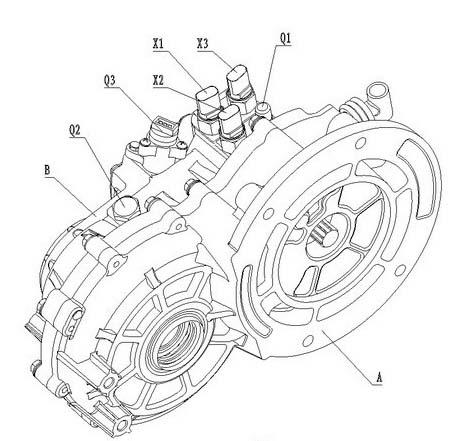

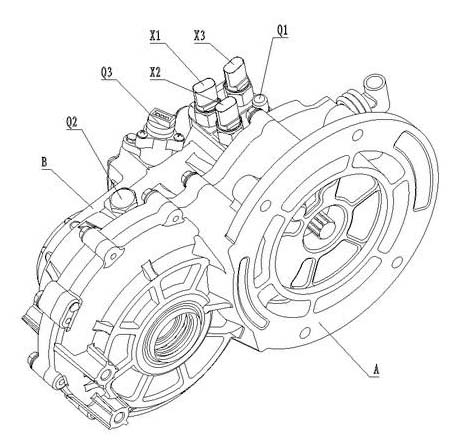

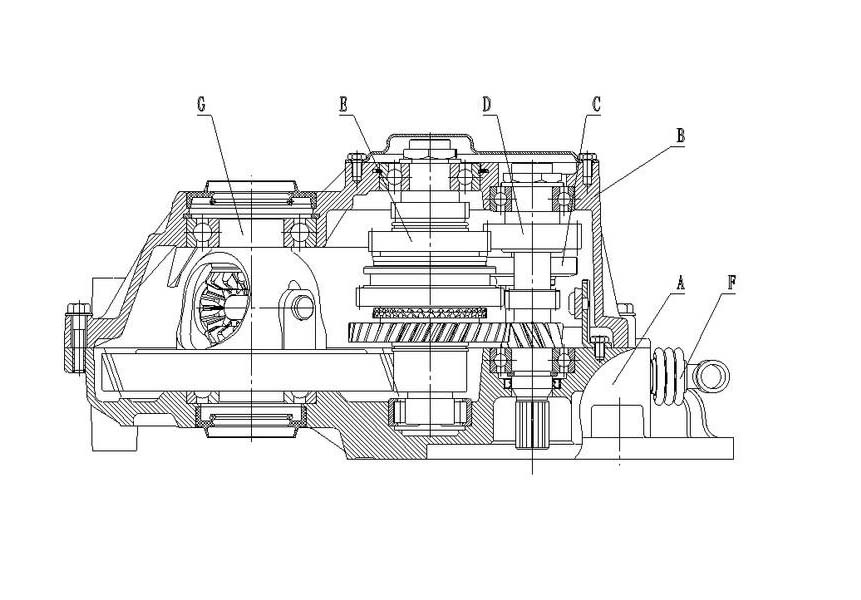

[0015] The following is a detailed description in conjunction with the drawings: As shown in the figure, the transmission front case A and the transmission rear case B are connected by bolts to form the case body, the drive shaft mechanism D is installed through the bearing, and the high-speed drive shaft is installed on the drive shaft of the drive shaft mechanism D. Gear D1, reverse driving gear D2, low-speed driving gear D3; install the reverse idler mechanism C through the installation holes of the transmission front case A and the transmission rear case B, and the reverse idler mechanism C is composed of: install on the idler shaft C2 Idler C1, return spring C3; the intermediate shaft mechanism E is installed through the bearing, and the intermediate shaft mechanism E is composed of: the main deceleration driving gear shaft E1 is installed with the low-speed driven gear E2, the synchronizer E3, the reverse gear driven gear E6, and the high-speed driven gear Gear E4, drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com