Heat pipe type heat exchanger for heat pump water heater

A heat pump water heater and heat pipe technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of low efficiency and high cost, and achieve the effects of ensuring safety and reliability, reducing the temperature difference of heat transfer, and improving the energy efficiency ratio of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

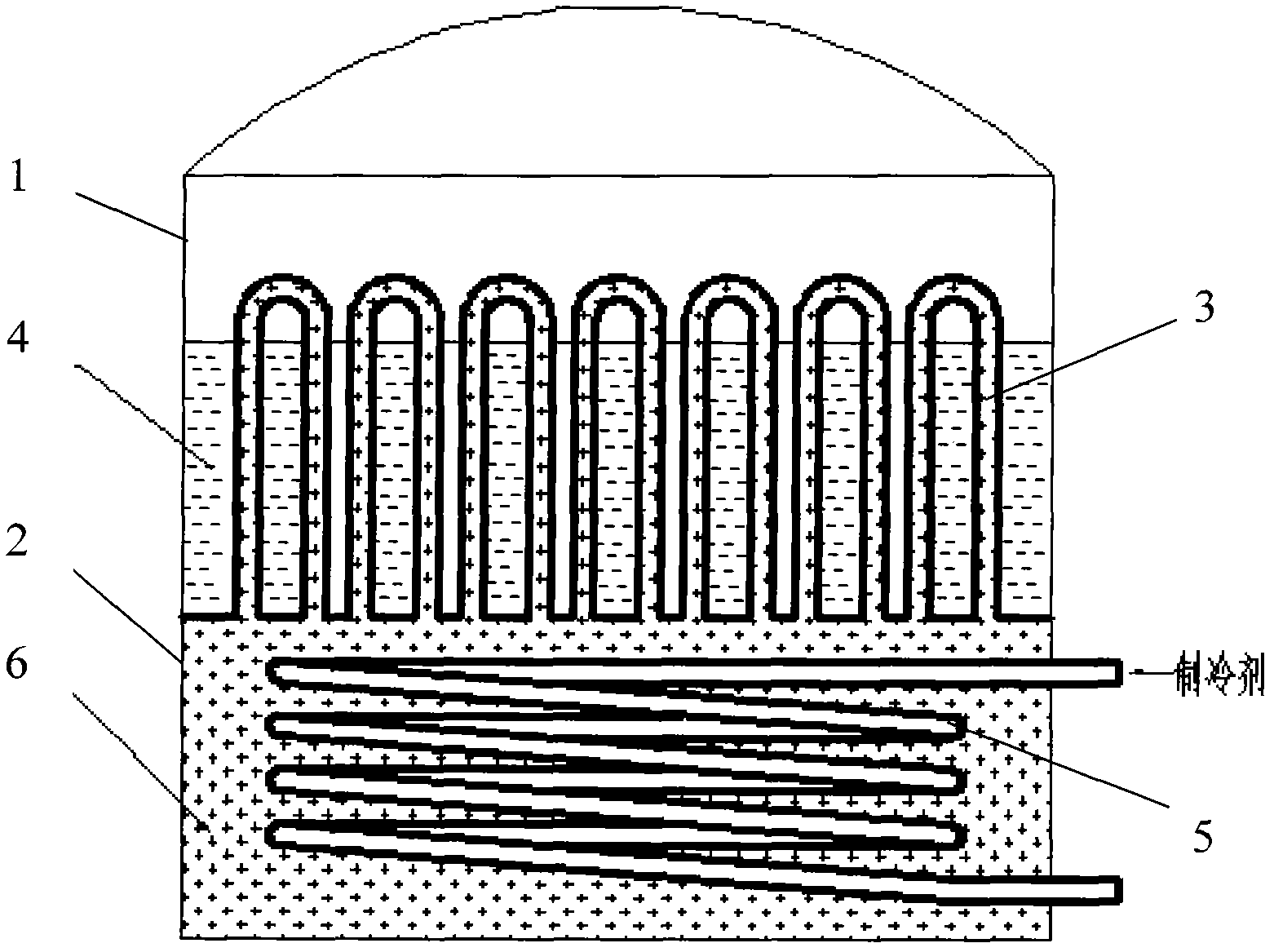

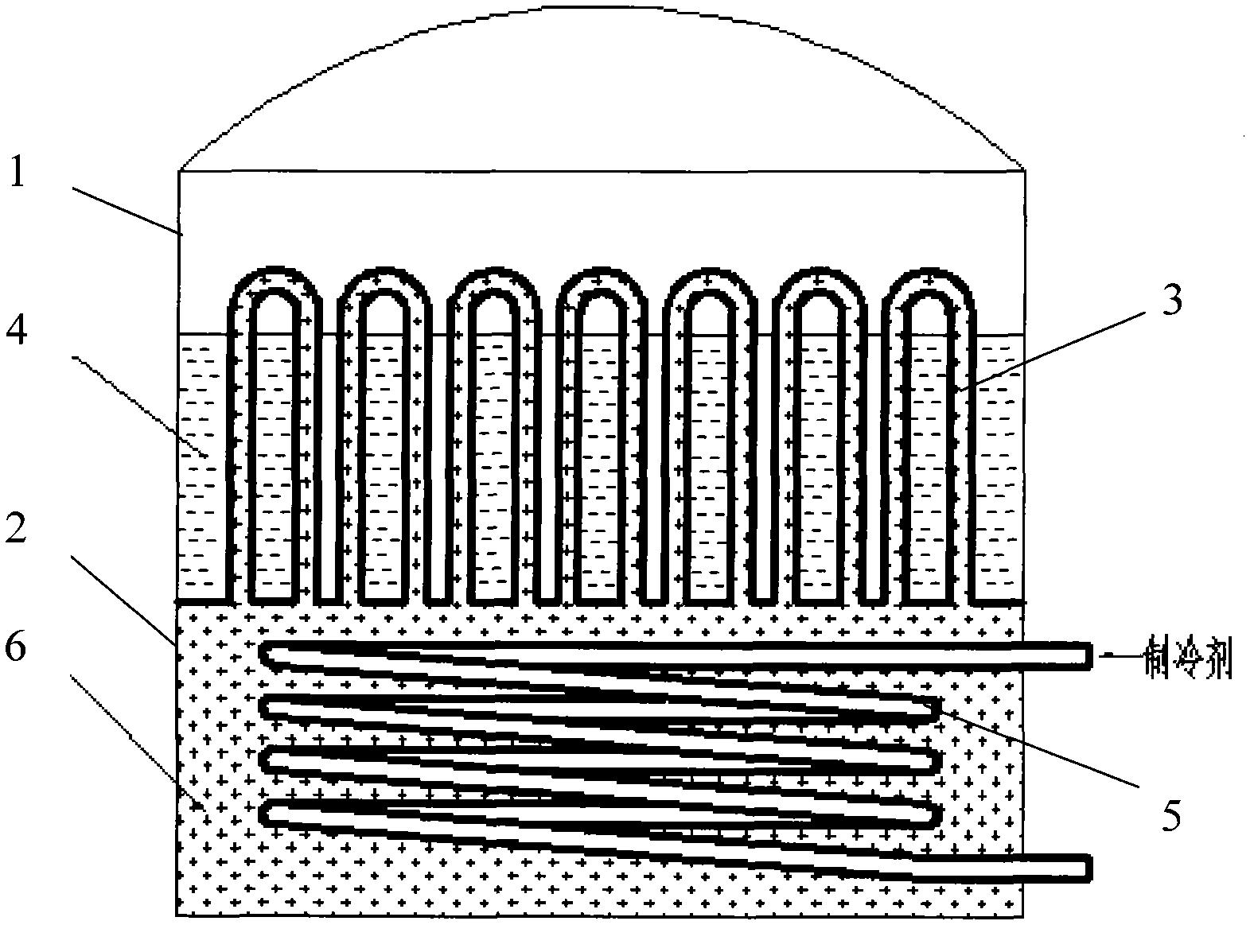

[0009] Such as figure 1 As shown, the heat pipe heat exchanger for heat pump water heaters includes a hot water tank 1 and a refrigerant tank 2, the refrigerant tank 2 is on the bottom, and the hot water tank 1 is on the top, which are isolated from each other and not connected; there are several in the hot water tank 1 The inverted U-shaped tube 3, the lower nozzle of the inverted U-shaped tube 3 communicates with the refrigerant tank 2, hot water 4 is stored in the hot water tank 1; there is a heat exchange coil 5 in the refrigerant tank 2, and the refrigerant tank 2 is evacuated , Refrigerant tank 2 is provided with brine 6.

[0010] The working process of the present invention is as follows: after the refrigerant in the refrigerant tank evaporates, it changes into a gaseous state and enters into the inverted U-shaped tube in the hot water tank. The function flows back to the refrigerant tank, and the hot water in the hot water tank is heated by the high-temperature gaseou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com