Method and device for lossless automatic approximation by facing nano observation and nano operation

A nano-operation and automatic technology, which is applied in the direction of measuring devices, instruments, scanning probe microscopy, etc., can solve problems such as difficult automatic approximation, high difficulty in realization, and prone to collisions, etc., to achieve a good approximation environment and eliminate other problems. Effects of factor interference and loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

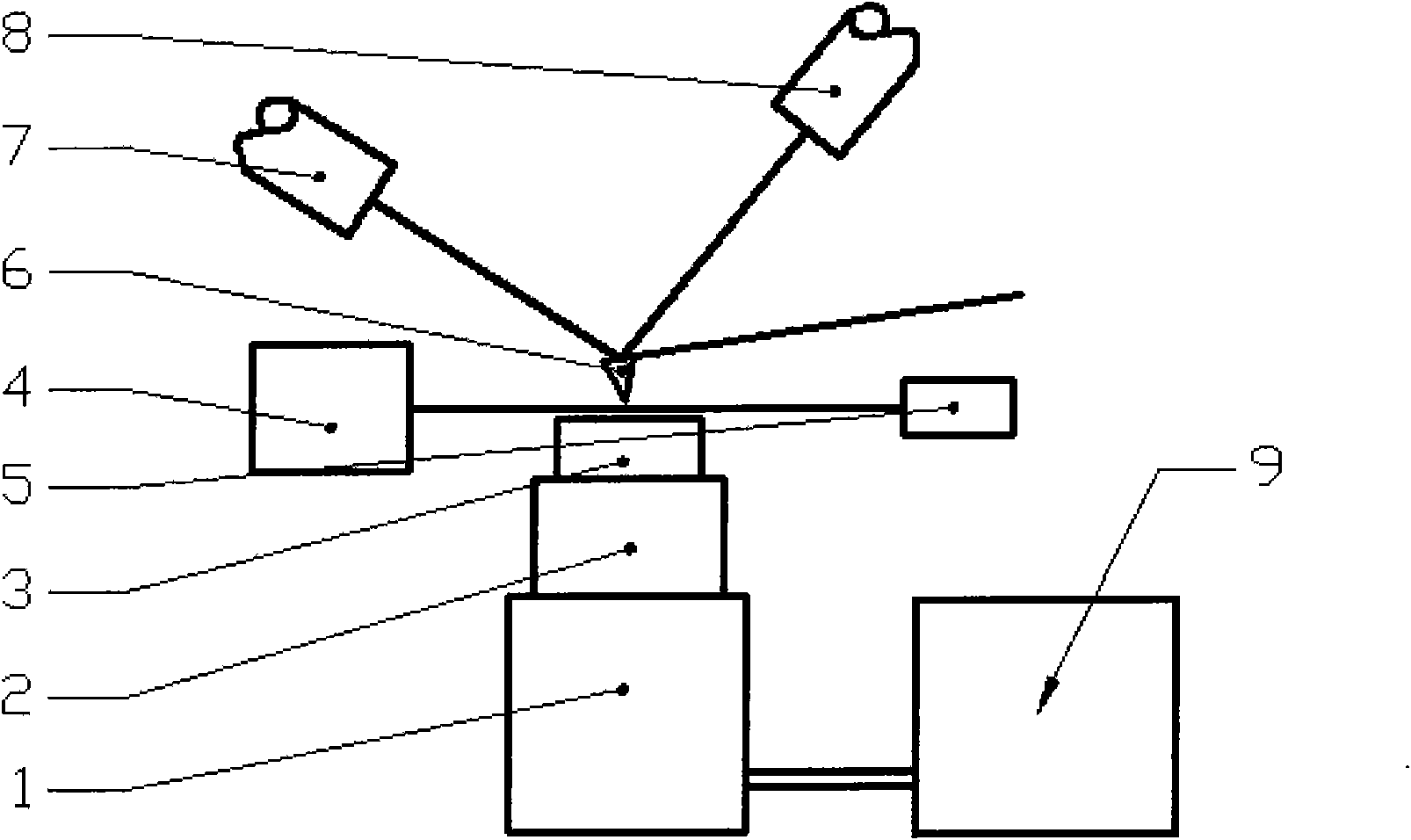

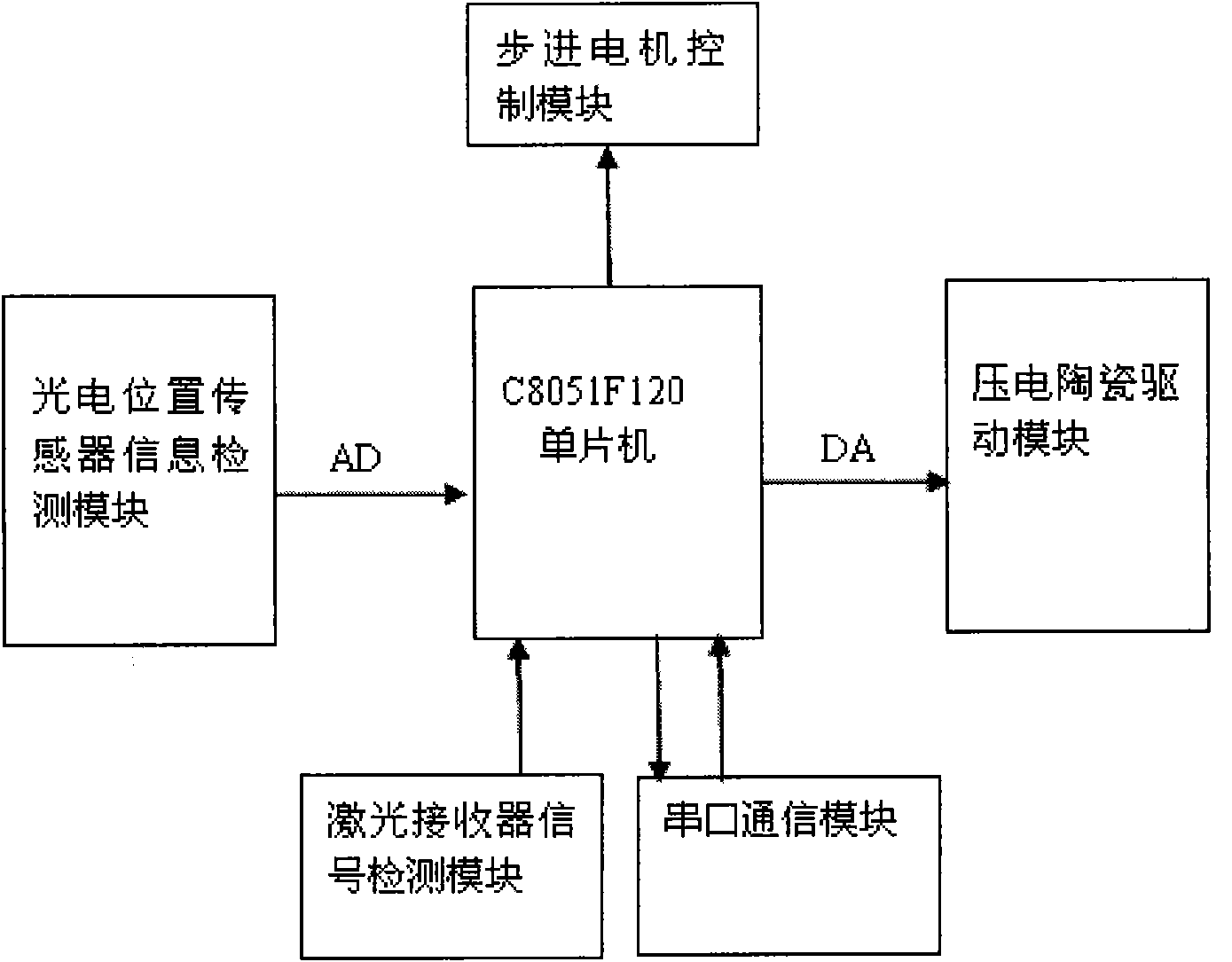

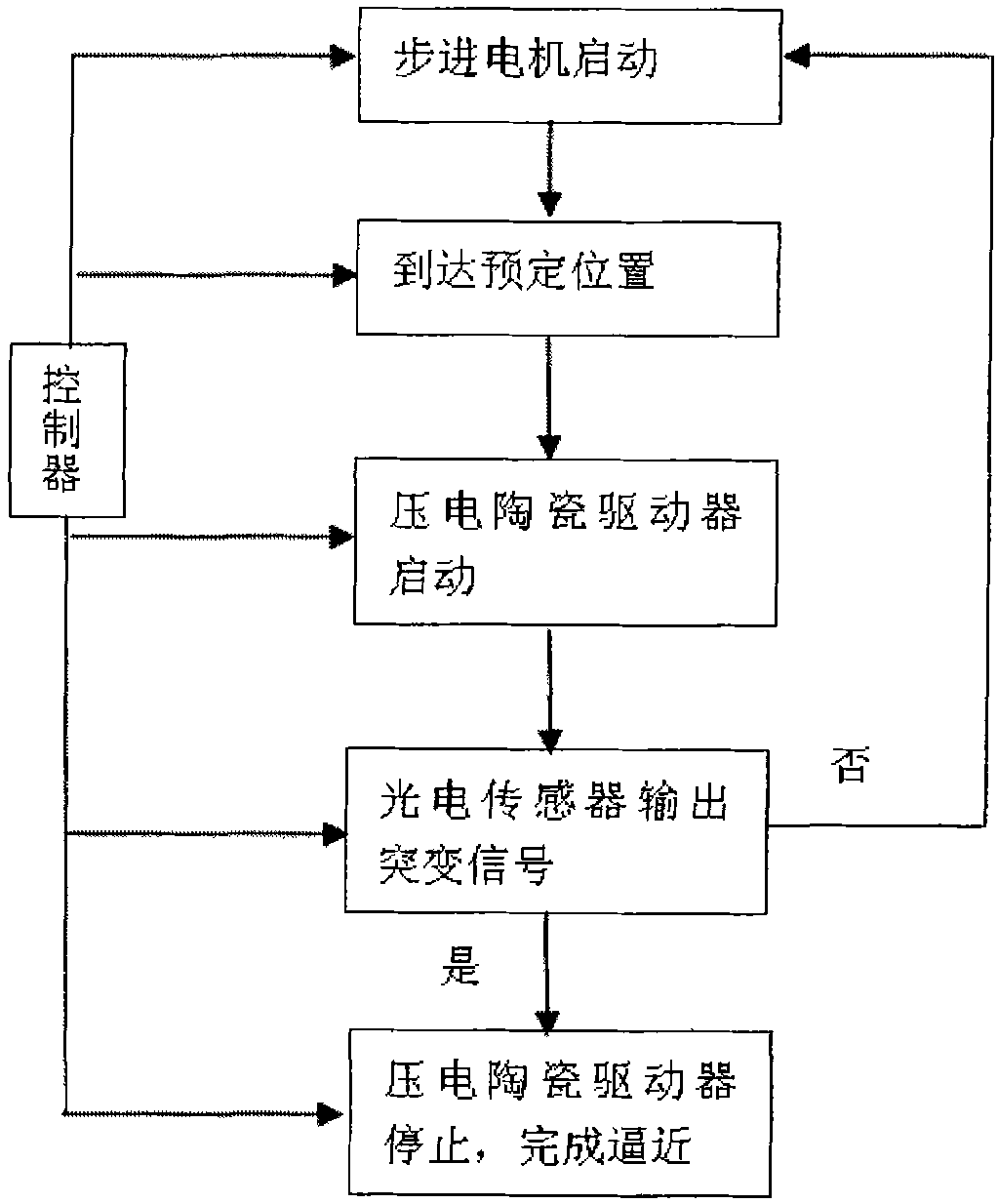

[0021] like figure 1 As shown, the device of the present invention includes a stepper motor 1, a piezoelectric ceramic driver 2, a sample stage 3, a laser transmitter 4, a laser receiver 5, a probe 6, a laser light source 7, a photoelectric sensor 8, and a controller 9. The controller 9 is electrically connected to each component, the stepper motor 1 is provided with a piezoelectric ceramic driver 2, the piezoelectric ceramic driver is provided with a sample stage 3, a probe 6 is arranged directly above the sample stage 3, and a laser source 7. The emitted laser light is reflected by the probe 6 to the photoelectric sensor 8. The laser emitter 4 and the laser receiver 5 are respectively arranged on both sides of the sample stage 3 and directly below the probe 6 and directly above the sample stage 3.

[0022] The laser emitted by the laser emitter 4 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com