Optical slice and backlight unit using it

An optical sheet and optical layer technology, applied in optical elements, optics, material analysis by optical means, etc., can solve problems such as insufficient adhesion prevention performance, insufficient protection against optical sheet damage, etc., and achieve high adhesion prevention function, Handling easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

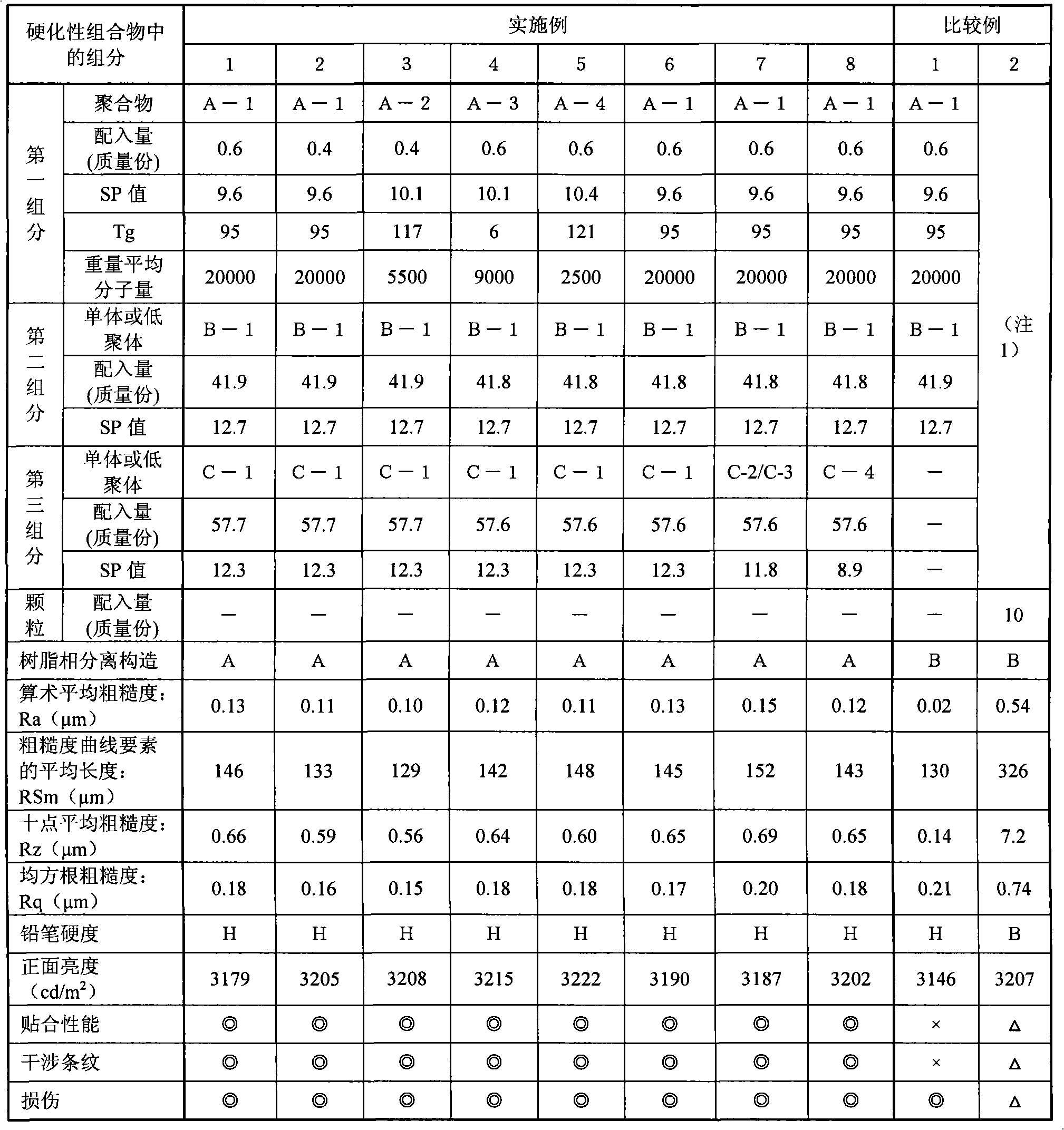

[0086] The present invention will be described in detail below based on the examples, but the present invention should not be limitedly interpreted based on the description of the examples.

Synthetic example 1

[0087] (Synthesis Example 1 [Synthesis of Unsaturated Double Bond-Containing Acrylic Copolymer (A-1)])

[0088] 100 parts by mass of propylene glycol monomethyl ether was placed in a 2 L reaction container equipped with a stirrer, a thermometer, a nitrogen introduction tube, a cooler, and a dropping funnel, and nitrogen substitution was performed, followed by heating to 110°C. Next, a mixture consisting of 50 parts by mass of isobornyl methacrylate, 1 part by mass of methyl methacrylate, and 3 parts by mass of methacrylic acid, and tert-butyl peroxide as a polymerization initiator were dropped at the same time for three hours. A mixture consisting of 0.5 parts by mass of 2-ethylhexanoate and 20 parts by mass of propylene glycol monomethyl ether. After completion of the dropping, the reaction was carried out at 110° C. for 1 hour. Then, a mixture consisting of 0.1 parts by mass of t-butyl peroxy-2-ethylhexanoate and 5 parts by mass of propylene glycol monomethyl ether was dr...

Synthetic example 2

[0090] (Synthesis Example 2 [Synthesis of Acrylic Copolymer (A-2)])

[0091] 100 parts by mass of propylene glycol monomethyl ether was placed in a 2 L reaction container equipped with a stirrer, a thermometer, a nitrogen introduction pipe, a cooler, and a dropping funnel, and nitrogen substitution was performed, followed by heating to 110°C. Next, a mixture consisting of 50 parts by mass of isobornyl methacrylate, 1 part by mass of methyl methacrylate, and 3 parts by mass of methacrylic acid, and tert-butyl peroxide as a polymerization initiator were dropped at the same time for three hours. A mixture consisting of 3 parts by mass of 2-ethylhexanoate and 20 parts by mass of propylene glycol monomethyl ether. It reacted at 110 degreeC for 30 minutes after completion|finish of dripping. Thus, an acrylic copolymer (A-2) was obtained. The number average molecular weight of the acrylic copolymer (A-2) was 3000, the weight average molecular weight was 5500, the SP value was 10....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com