Light-emitting device and lighting appliance

A light-emitting device and light-emitting element technology, which is applied to semiconductor devices of light-emitting elements, lighting devices, lighting and heating equipment, etc., can solve the problems of insulation core damage, warping, and poor quality, and achieve stable life, suppress warping, The effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

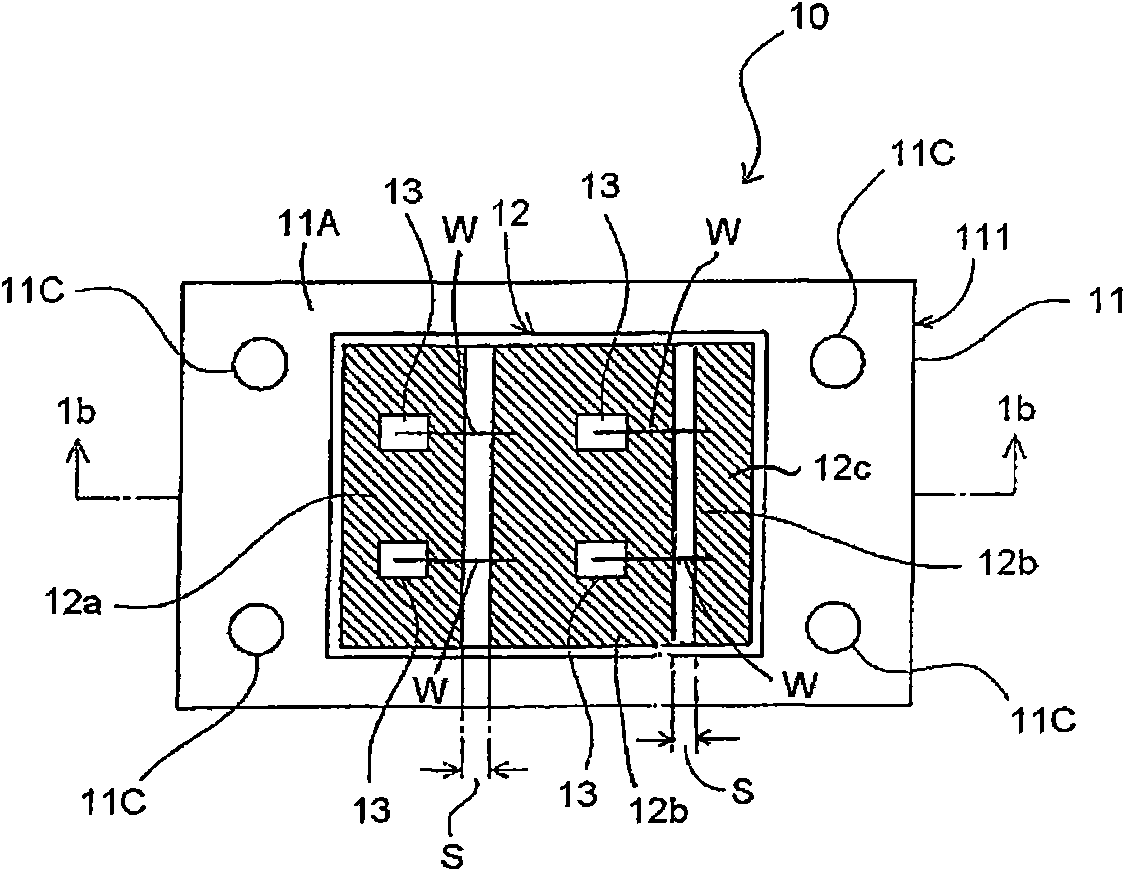

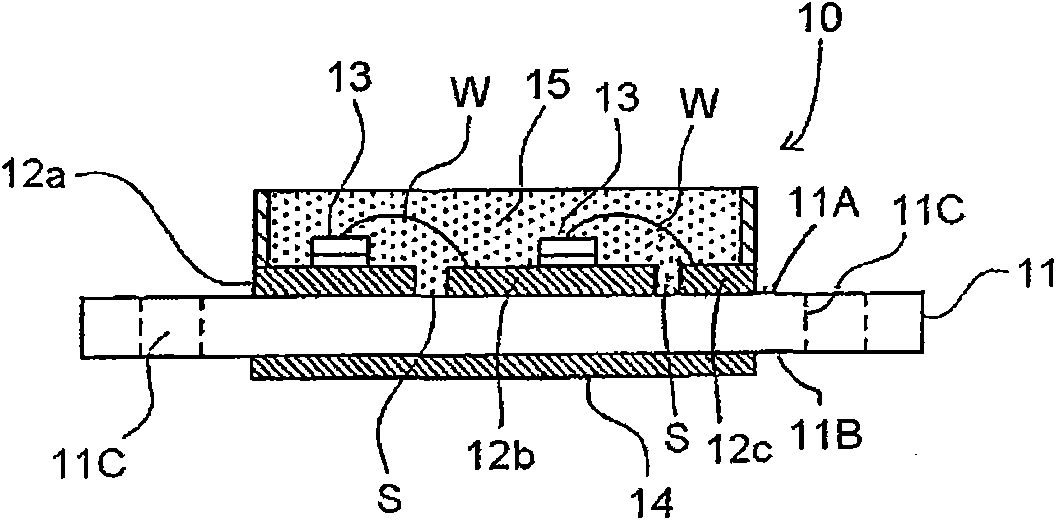

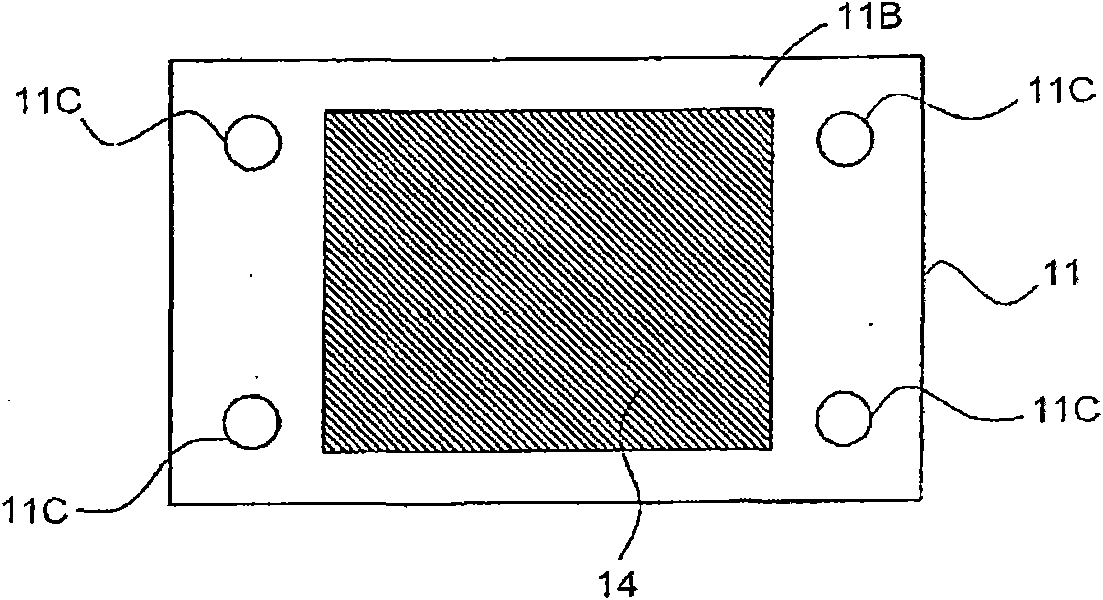

[0081] A light emitting device according to one embodiment includes an insulating base, a front metal member, a semiconductor light emitting element, and a rear metal member. The insulating base is made of ceramics. The front metal component is divided and arranged on the surface of the insulating base. The semiconductor light emitting element is installed on the front metal component. The rear metal member is formed on the rear surface of the insulating base with the same or thinner thickness as that of the front metal member. The volume of the back metal member is 50% or more compared with the volume of the front metal member.

[0082] The insulating base, the front metal component and the back metal component constitute the substrate. Examples of the substrate include a DCB (Direct Copper Bonding) substrate, a Direct Brazing Aluminum (DBA) substrate, an Active Metal Brazed Copper (AMC) substrate, and the like. The DCB substrate is formed by directly bonding a copper pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com