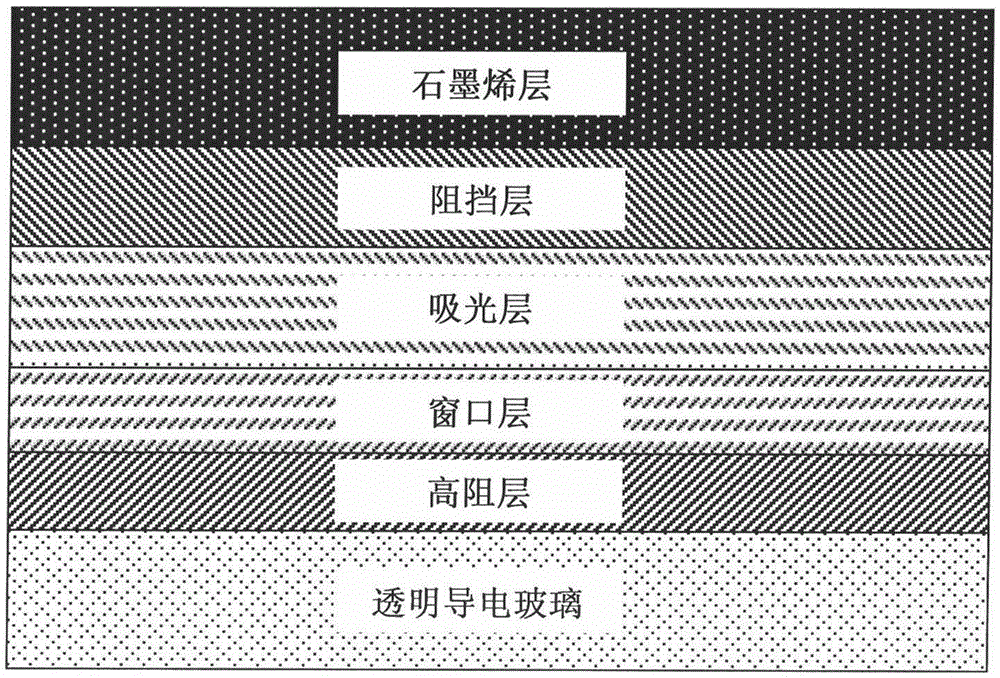

Back contact electrode in cadmium telluride thin film solar cell structure and preparation method

A solar cell and back contact electrode technology, applied in the field of microelectronics, can solve the problems of not being able to form ohmic contact, affecting carrier conduction, and not considering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Preparation of transparent conductive layer: AZO conductive glass is prepared by sputtering method, the temperature of the glass substrate is 600°C at room temperature, the carrier gas is argon or argon-hydrogen mixed gas (where the hydrogen is less than 10%), the reaction pressure is 0.1Pa, and the gas flow rate is 5sccm (standard cubic centimeter per minute, standard cubic centimeter per minute), the power is 50W, the target distance is 5cm, where N 2 as a carrier gas. The deposition thickness is about 600nm. Obtain the transparent conductive glass ( figure 2 ).

[0044] Window layer preparation: prepared by sputtering method, the temperature of the conductive glass substrate is room temperature, the reaction pressure is 0.1Pa, the power is 100W, and the target material is CdS target, where N 2 As a carrier gas, the gas flow rate was 5 sccm. The deposition thickness is about 100nm ( image 3 ).

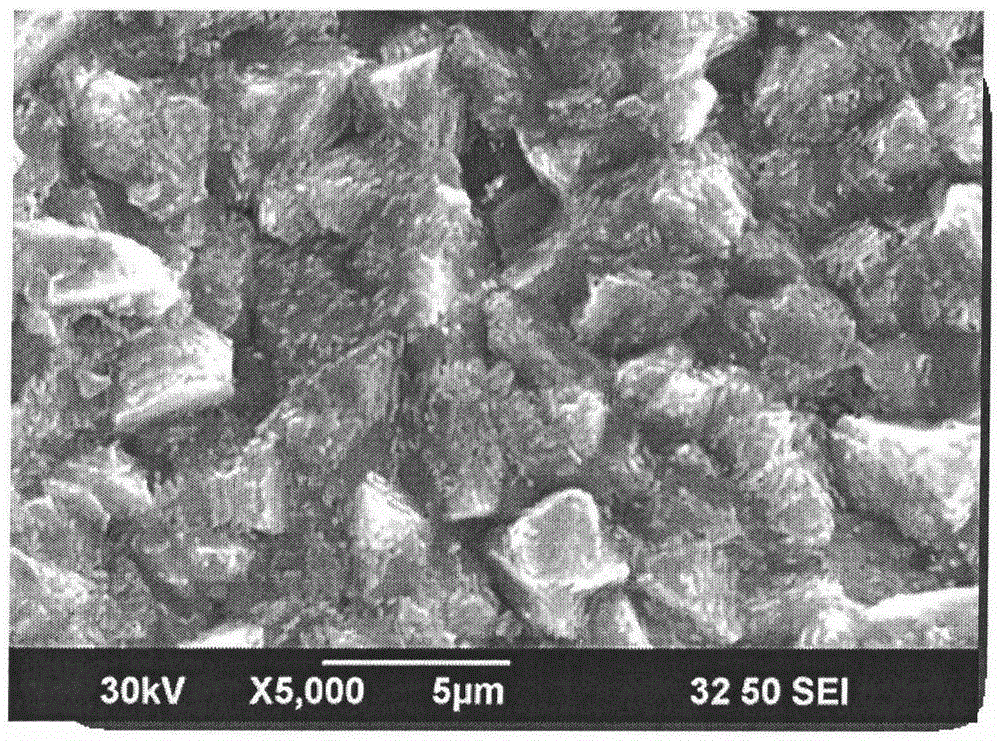

[0045] Preparation of light-absorbing layer: prepared by sputteri...

Embodiment 2

[0049] Preparation of transparent conductive layer: LPCVD is used to deposit FTO conductive glass, the substrate temperature is 400°C, the reaction pressure is 3kPa, the reaction precursor is Tetramethyltin (TMT), Bromotrifluoromethane (CBrF3) gas provides F source, and at the same time, O 2 and N 2 , where N 2 as a carrier gas. The deposition thickness is about 500nm.

[0050] Window layer preparation: prepared by sputtering method, the temperature of the conductive glass substrate is room temperature, the reaction pressure is 0.1Pa, the power is 100W, and the target material is CdS target, where N 2 As a carrier gas, the gas flow rate is 5 sccm. The deposition thickness is about 100 nm. .

[0051] Preparation of light-absorbing layer: prepared by sputtering method, the temperature of the above substrate is 300°C, the reaction pressure is 0.1Pa, the power is 100W, argon or argon-oxygen mixed gas is used as the carrier gas, the gas flow rate is 5 sccm, the target material...

Embodiment 3

[0056] Preparation of transparent conductive layer: LPCVD is used to deposit FTO conductive glass, the substrate temperature is 400°C, the reaction pressure is 3kPa, the reaction precursor is Tetramethyltin (TMT), Bromotrifluoromethane (CBrF3) gas provides F source, and at the same time, O 2 and N 2 , where N 2 as a carrier gas. The deposition thickness is about 500nm.

[0057] Preparation of the window layer: The CdS layer was prepared by the chemical water bath method, and the reactants were ammonium acetate, cadmium acetate, ammonia water and thiourea. First, add deionized water into a sealed container, heat it to 80°C, add cadmium acetate, ammonium acetate, and ammonia water, and deposit a thickness of about 100nm.

[0058] Preparation of light-absorbing layer: prepared by sputtering method, the temperature of the above substrate is 300°C, the reaction pressure is 0.1Pa, the power is 100W, argon or argon-oxygen mixed gas is used as the carrier gas, the gas flow rate is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com