Ball type motor with three-dimensional topology magnetic pole distribution structure

A magnetic pole, spherical technology, applied in the magnetic circuit shape/style/structure, electric components, electrical components, etc., can solve the problems of large mass and inertia, singular kinematics of joints, too small tilting moment, etc., to overcome the friction torque If it is too large, the effect of increasing the interaction force and expanding the output torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

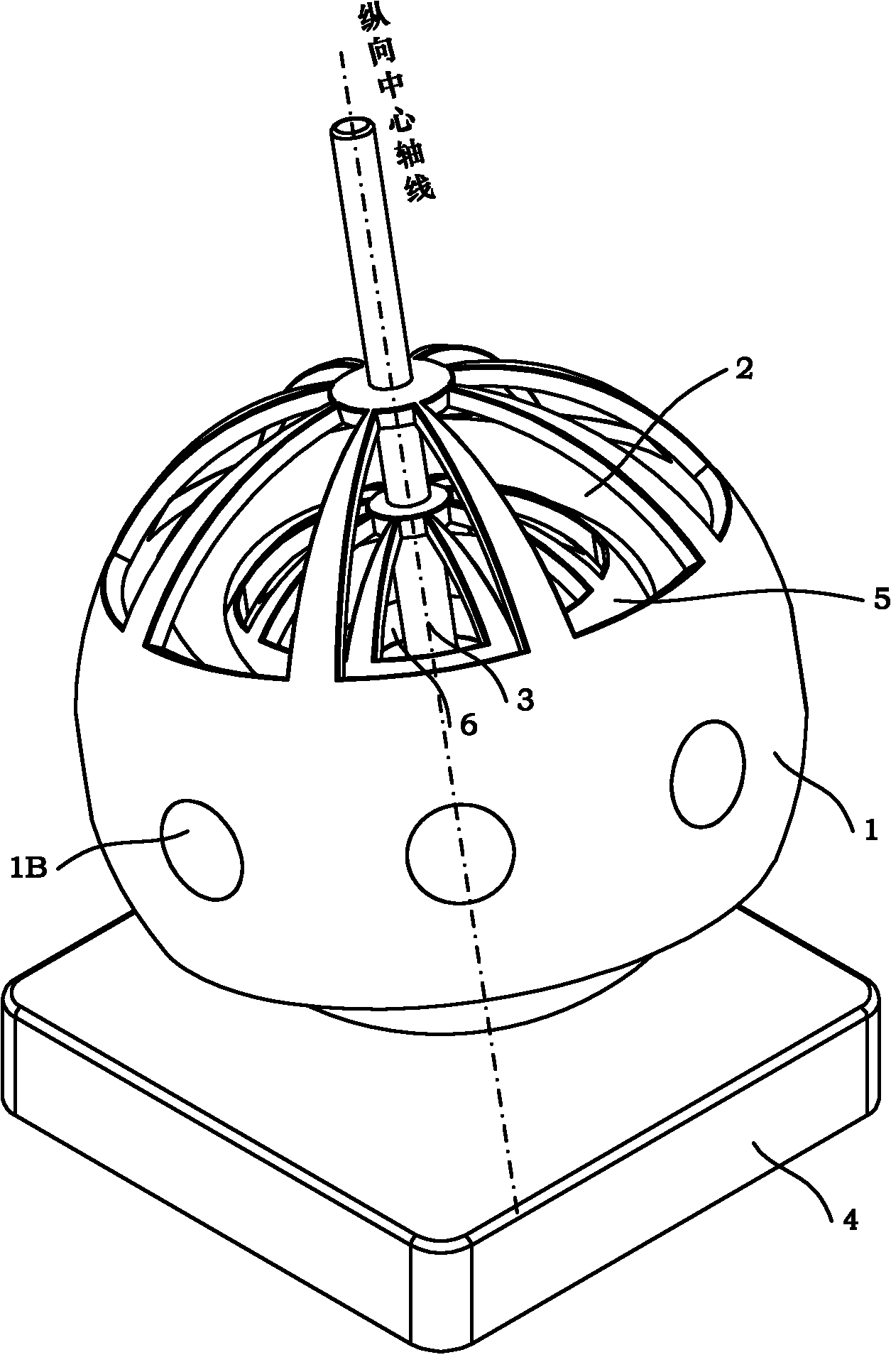

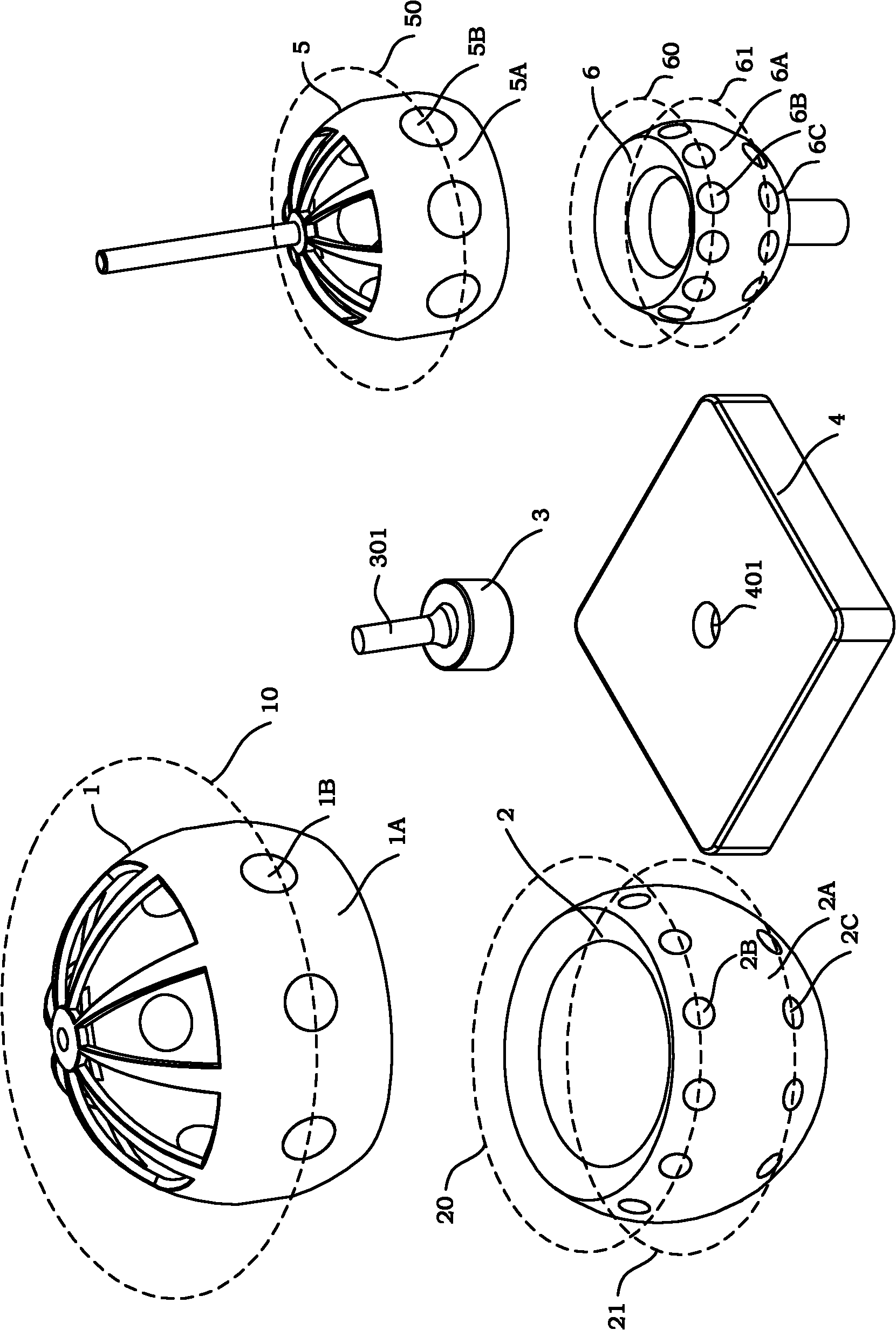

[0044] see figure 1 , Figure 1A As shown, a spherical motor with a three-dimensional topology magnetic pole distribution structure of the present invention, the spherical motor includes an outer rotor 1, an outer stator 2, a ball bearing 3, a base 4, an inner rotor 5 and an inner stator 6;

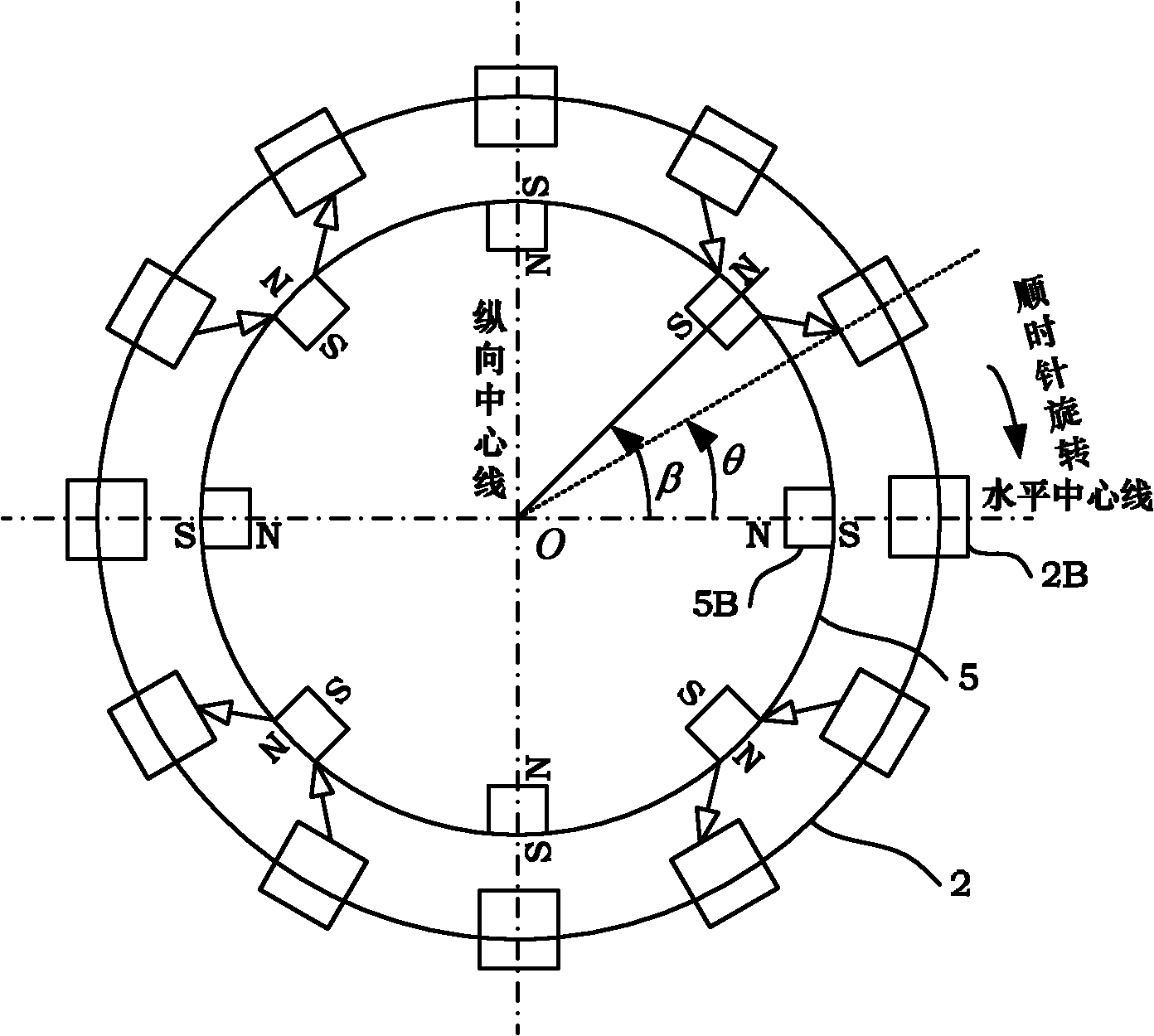

[0045] The rotor shell 1A of the outer rotor 1 (i.e., the outer rotor shell 1A) is equipped with a plurality of outer magnetic poles 1B, and the outer magnetic poles 1B are evenly distributed on the outer rotor latitude 10, and each outer magnetic pole 1B is arranged on the outer rotor latitude 10. The number satisfies β=n / 360, n represents the number of magnetic poles set, β represents the angle between the magnetic pole axis, unit °;

[0046] A plurality of inner magnetic poles 5B are installed on the rotor shell 5A of the inner rotor 5 (that is, the inner rotor shell 5A), and the inner magnetic poles 5B are evenly distributed on the inner rotor latitude 50, and the inner magnetic pole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com