Plasma processing device, plasma processing method, and mechanism for regulating temperature of dielectric window

A plasma and processing device technology, applied in the field of plasma processing device and temperature adjustment mechanism, can solve the problems of process gas decomposition, process gas excitation efficiency change, etc., and achieve the effect of uniform temperature distribution and good processing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, a plasma processing apparatus according to an embodiment of the present invention will be described in detail with reference to the drawings. In addition, the same reference numerals are assigned to the same or corresponding parts in the drawings, and the description thereof will not be repeated.

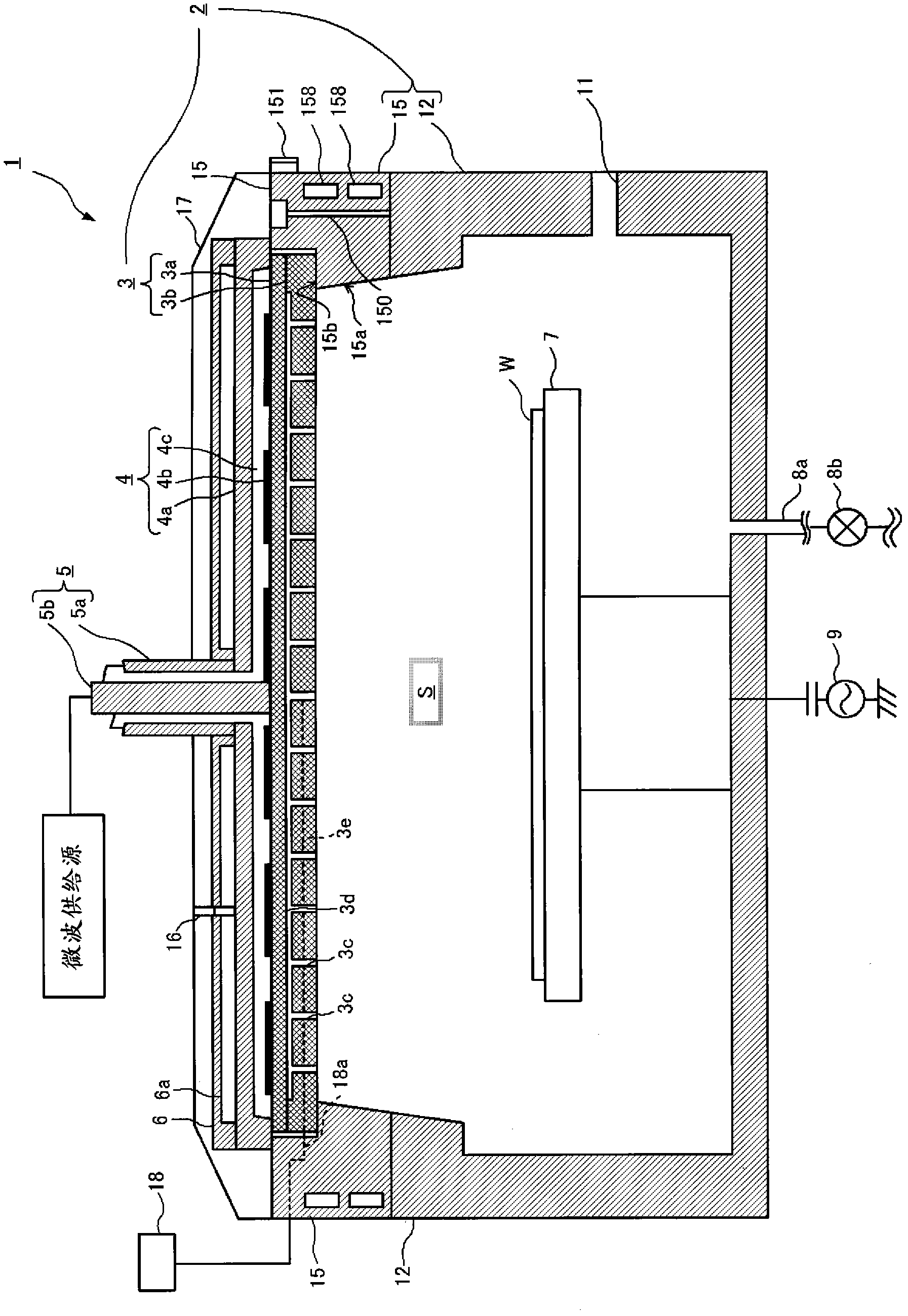

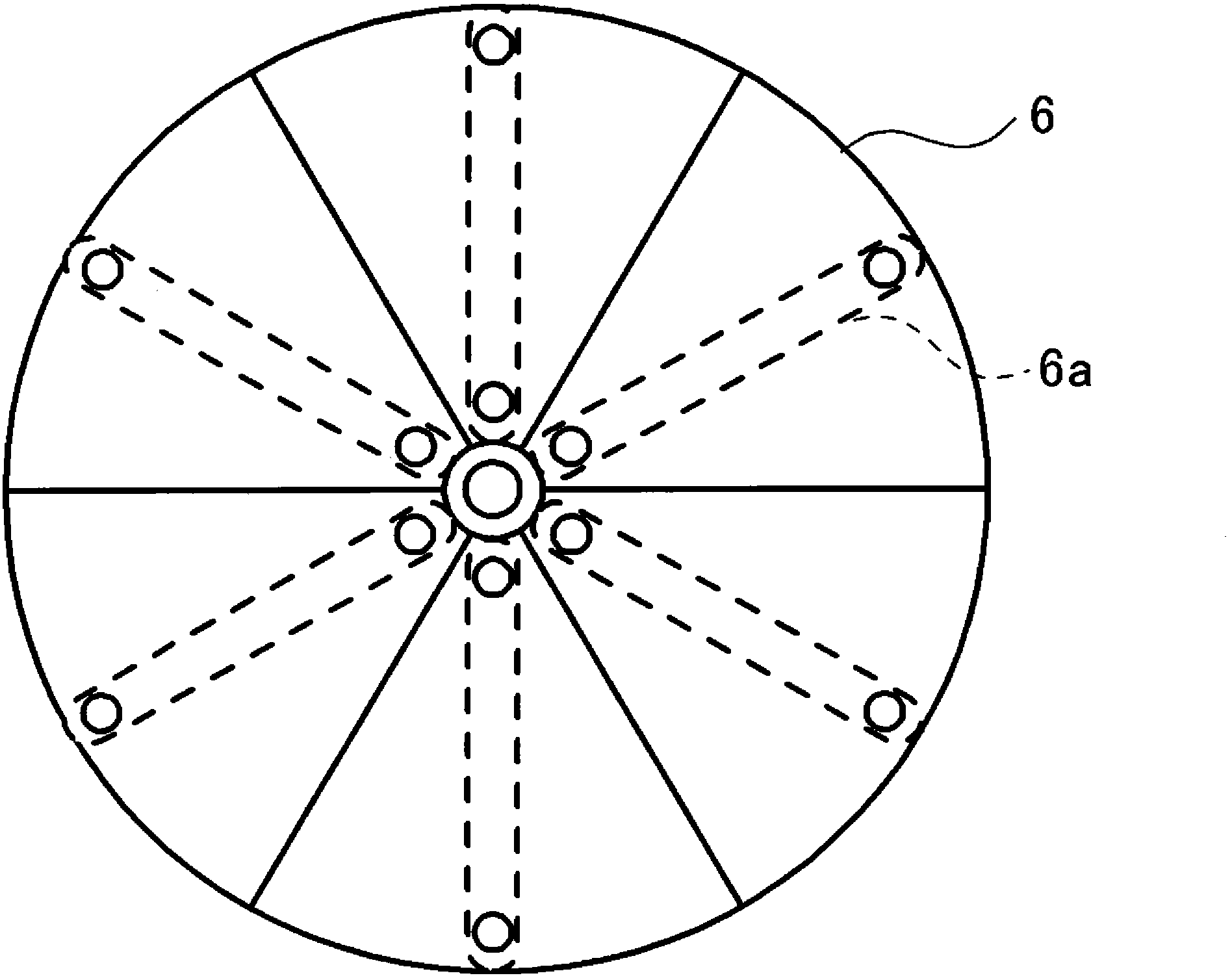

[0039] like figure 1 As shown, a plasma processing apparatus 1 has a processing container (chamber) 2, an antenna 4, a waveguide 5, a cooling block 6, a substrate holding table 7, an exhaust port 8a, a vacuum pump 8b, a high-frequency power supply 9, a door 11, a temperature Sensor 16 , cover 17 , gas supply 18 .

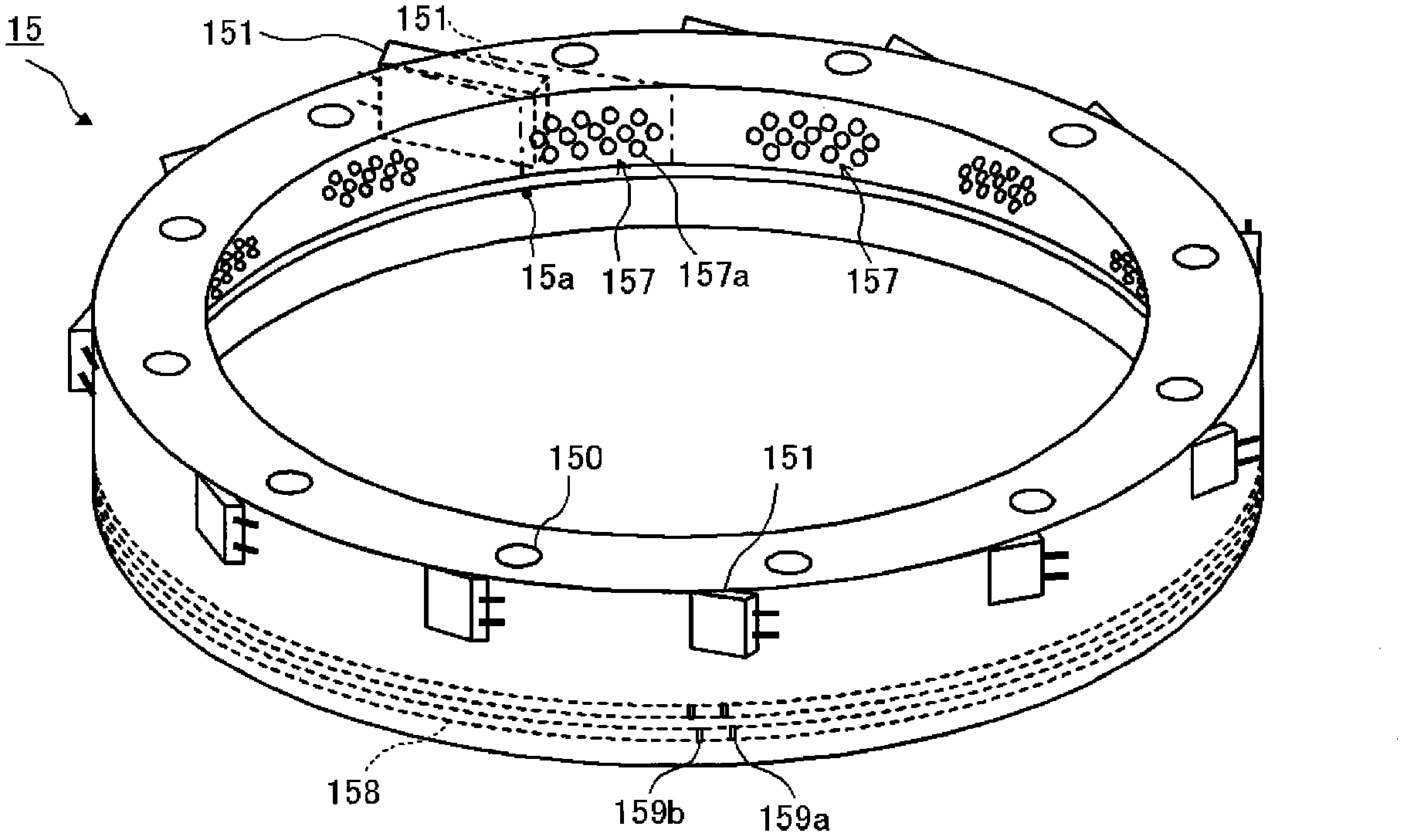

[0040] The processing container 2 has a lower container 12 , a holding ring (upper plate) 15 , and a dielectric window (shower plate) 3 .

[0041] The processing container 2 is configured to be sealable. By sealing the processing container 2, the pressure inside the processing container 2 can be maintained at a predetermined value. Furthermore, by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com