Automatic control system of vehicle door pallet transshipping mechanism

An automatic control system and vehicle door technology, applied in the field of conveyor control, can solve the problems that do not conform to the flexibility, automation, and efficiency of automobile production equipment, the door clamp cannot be automatically disassembled, and the process installation is inconvenient. Reduced maintenance time and stable pallet transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings and embodiments.

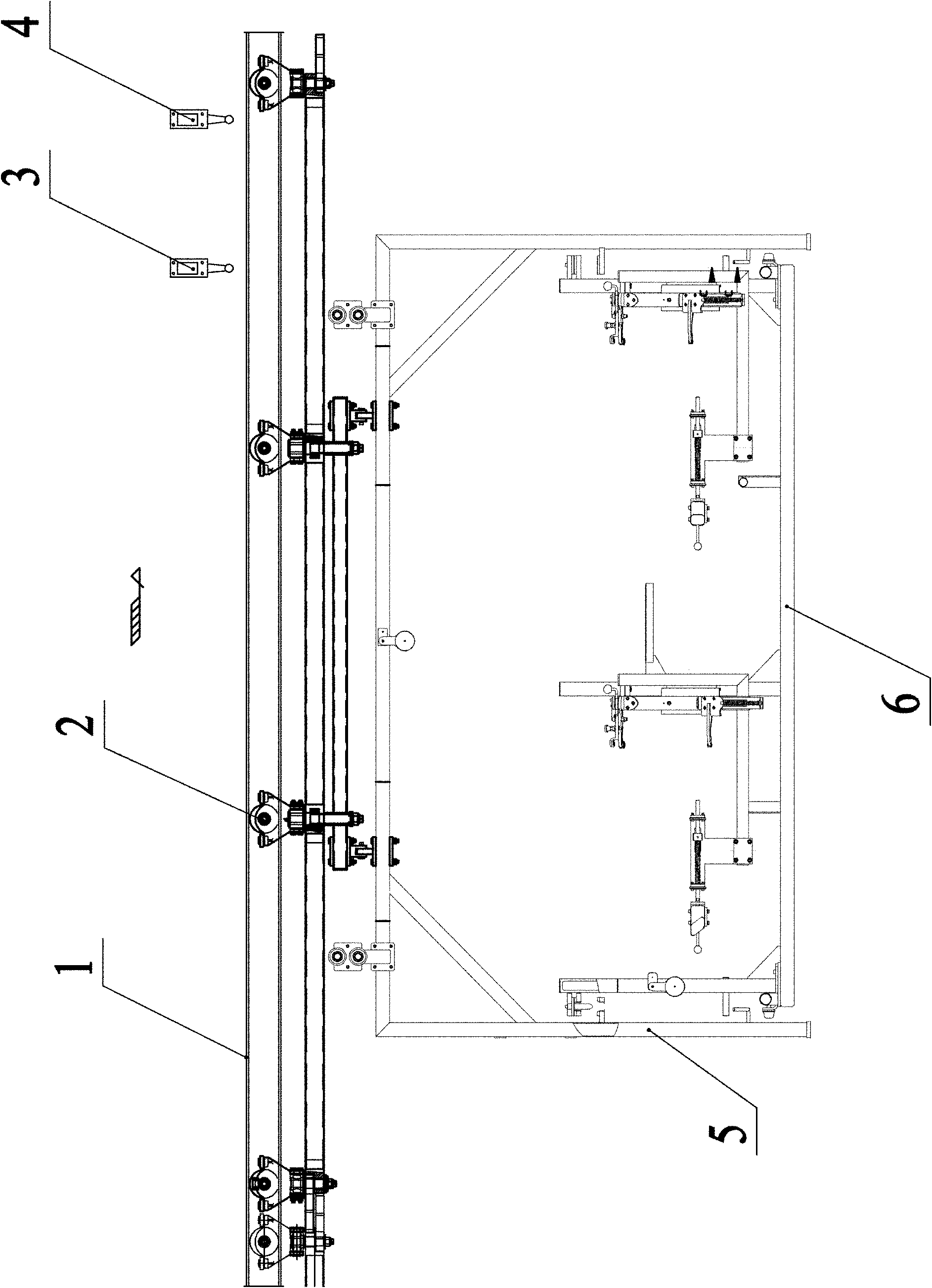

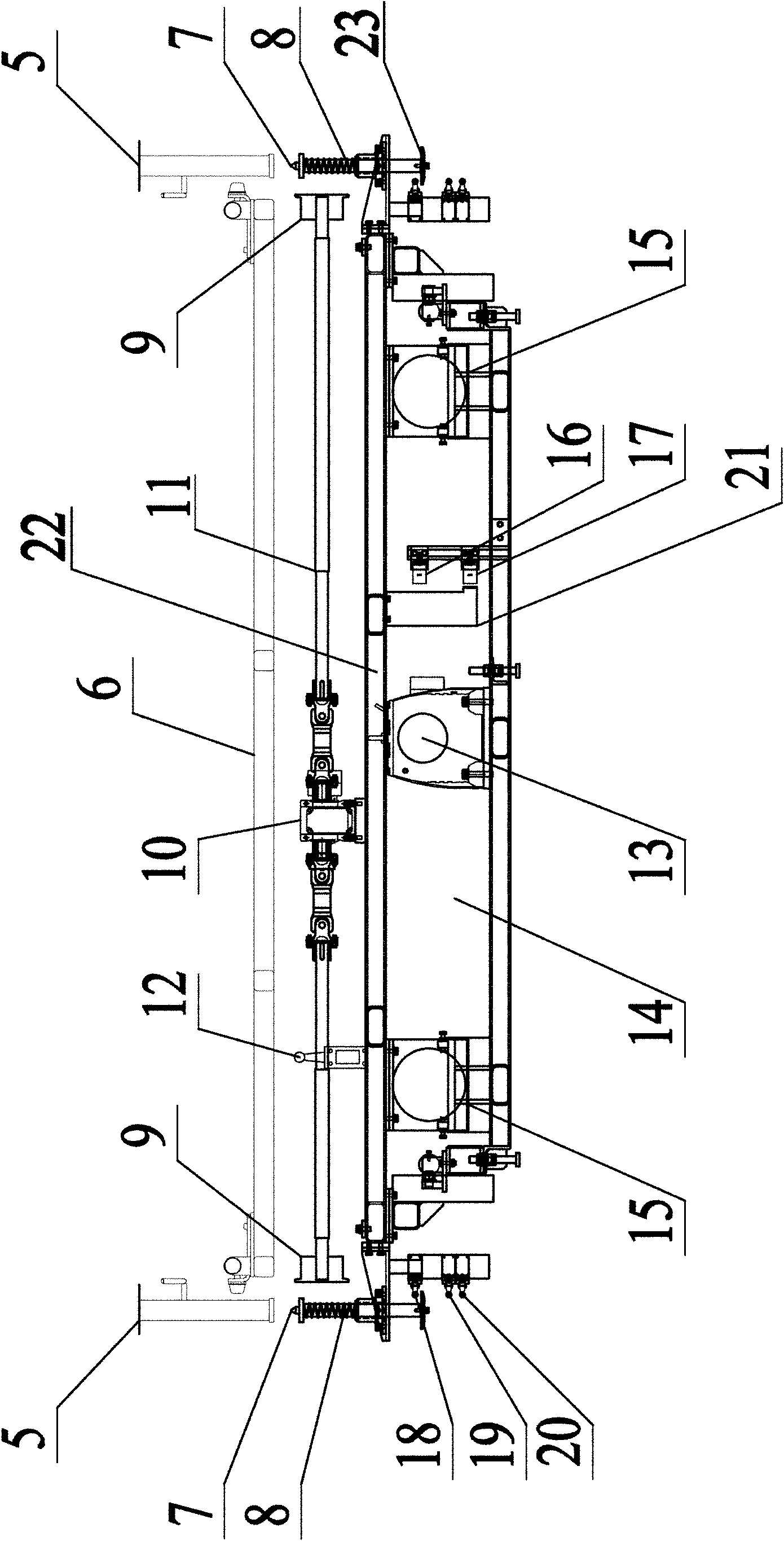

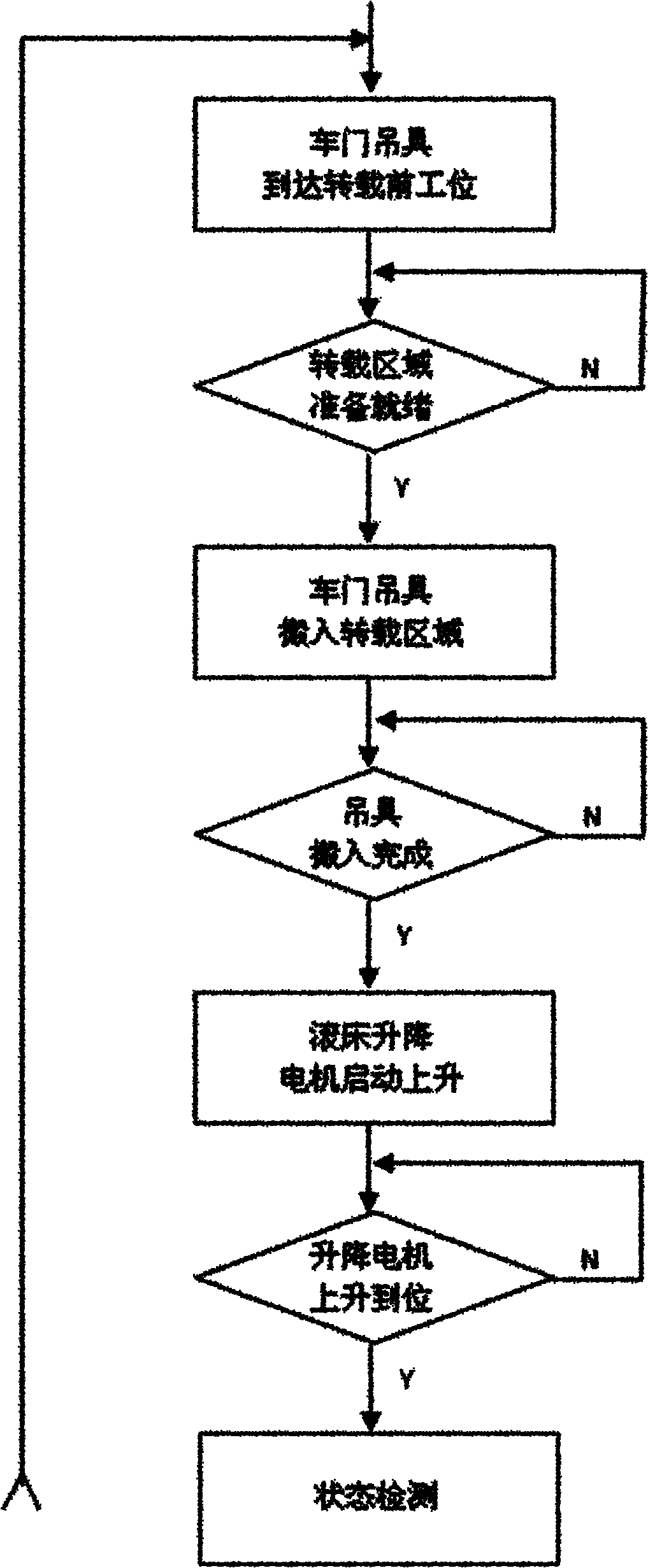

[0016] As shown in the figure, the present invention mainly consists of a conveying track 1, a trolley group 2, a spreader deceleration switch 3, a spreader stop switch 4, a door spreader 5, a door tray 6, a positioning pin 7, a spring 8, a roller 9, a roller Drum driving motor 10, roller drive shaft 11, pallet detection switch 12, roller bed lifting motor 13, roller bed lifting drive belt 14, roller bed lifting drive wheel 15, roller bed in-position switch 16, roller bed down-position switch 17, positioning super Limit switch 18, positioning normal switch 19, positioning failure switch 20, roller bed sending number block 21, lifting roller bed 22 and positioning switch trigger sheet 23 and other parts constitute.

[0017] The automatic control system of the door tray reloading mechanism includes a trolley group 2 slidingly running on the conveying track 1, a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com