Model-based dynamically decoupling turbine-boiler coordination control method for thermal power unit

A dynamic decoupling, thermal power unit technology, applied in the control system, steam generation, lighting and heating equipment, etc., can solve the problems of main steam pressure fluctuation, system coupling, object lag, etc., to overcome the lag and improve the response rate , to ensure the effect of response quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

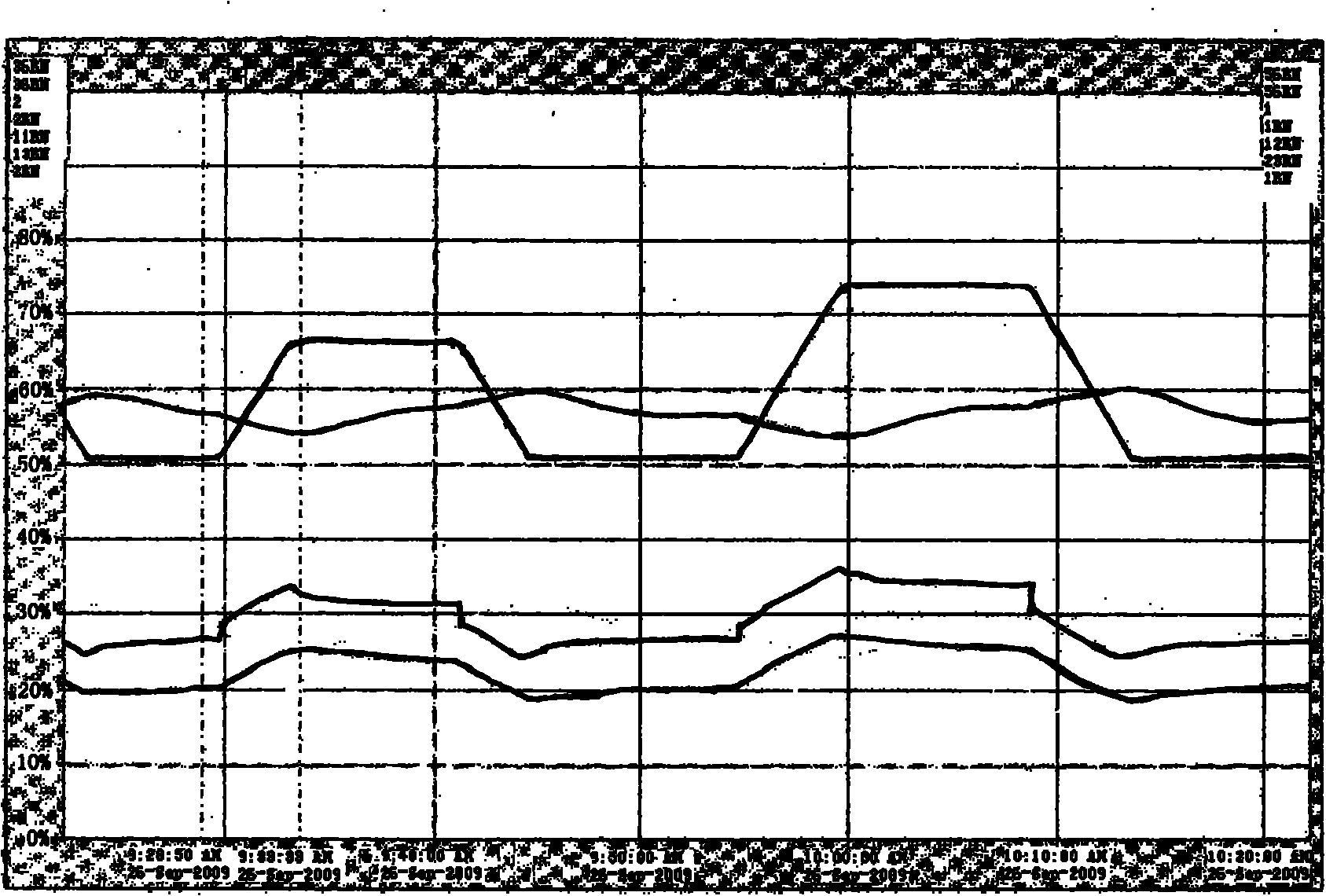

Examples

Embodiment Construction

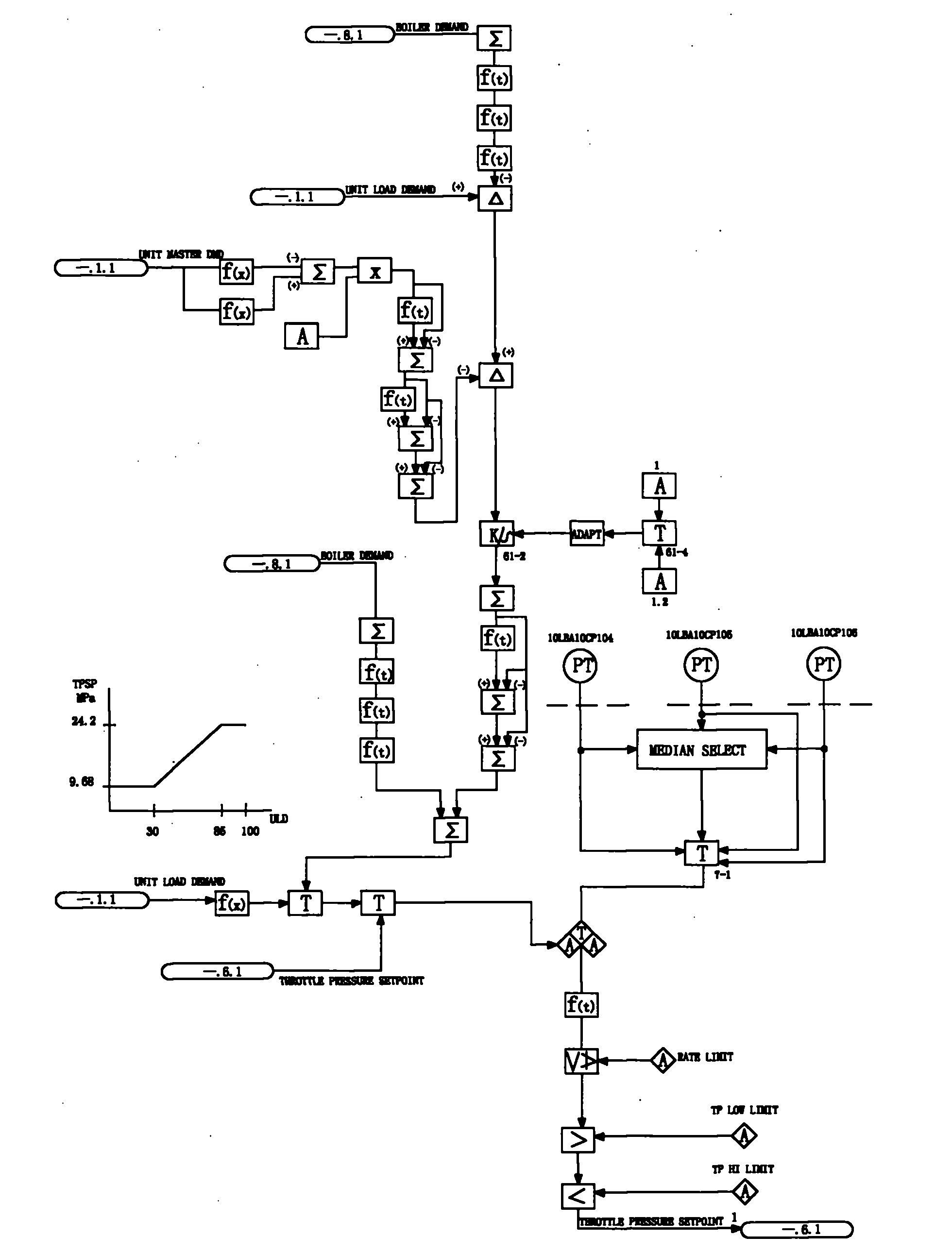

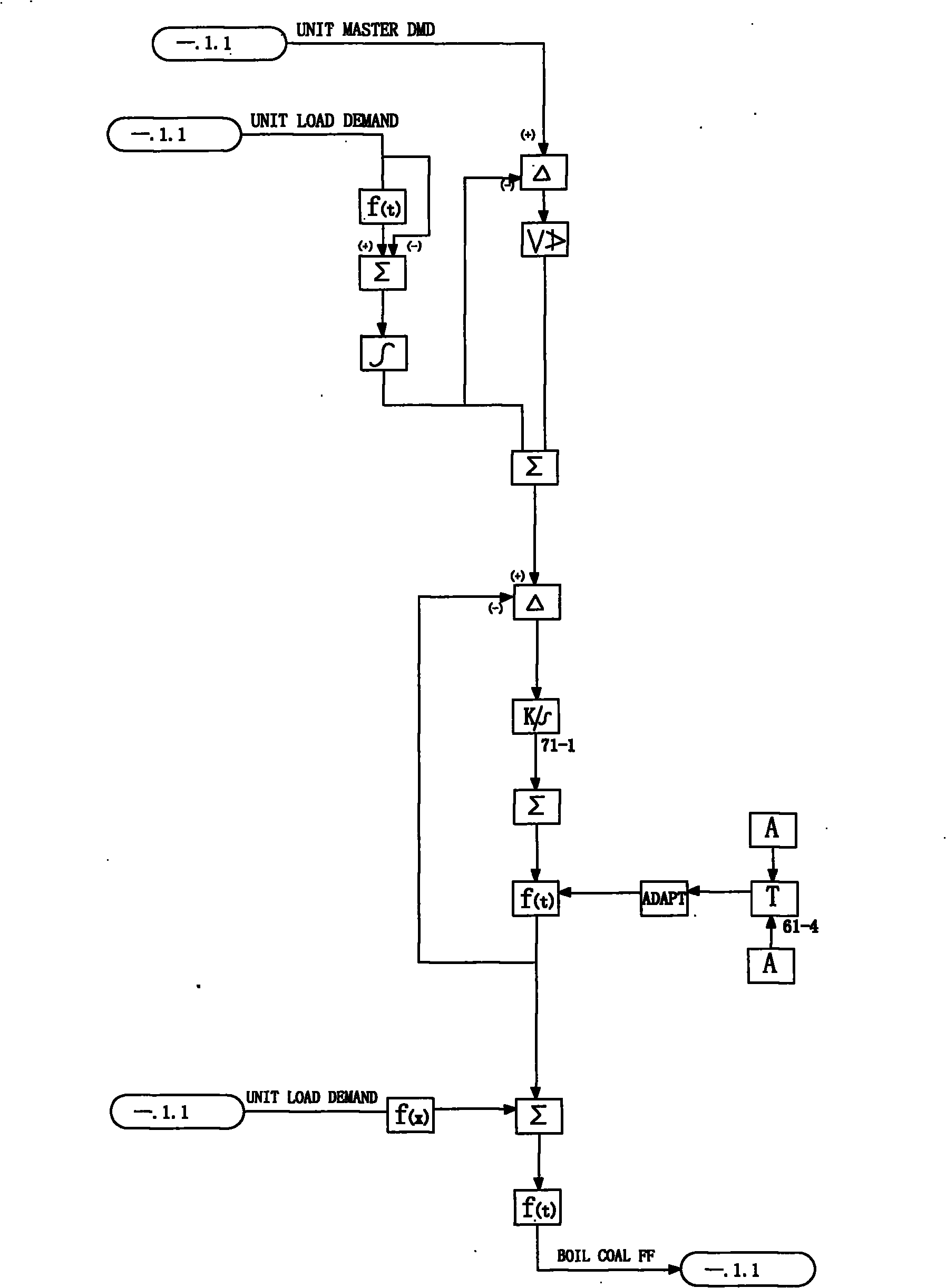

[0029] 1. Estimated coal volume feed-forward strategy

[0030] By simplifying and linearizing the nonlinear model, an approximate dynamic model (unit model for short) of the coordinated control system of the unit unit can be obtained:

[0031] Δ p T ΔN = g 11 g 12 g 21 g 22 ΔB Δμ = k 1 μ ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com