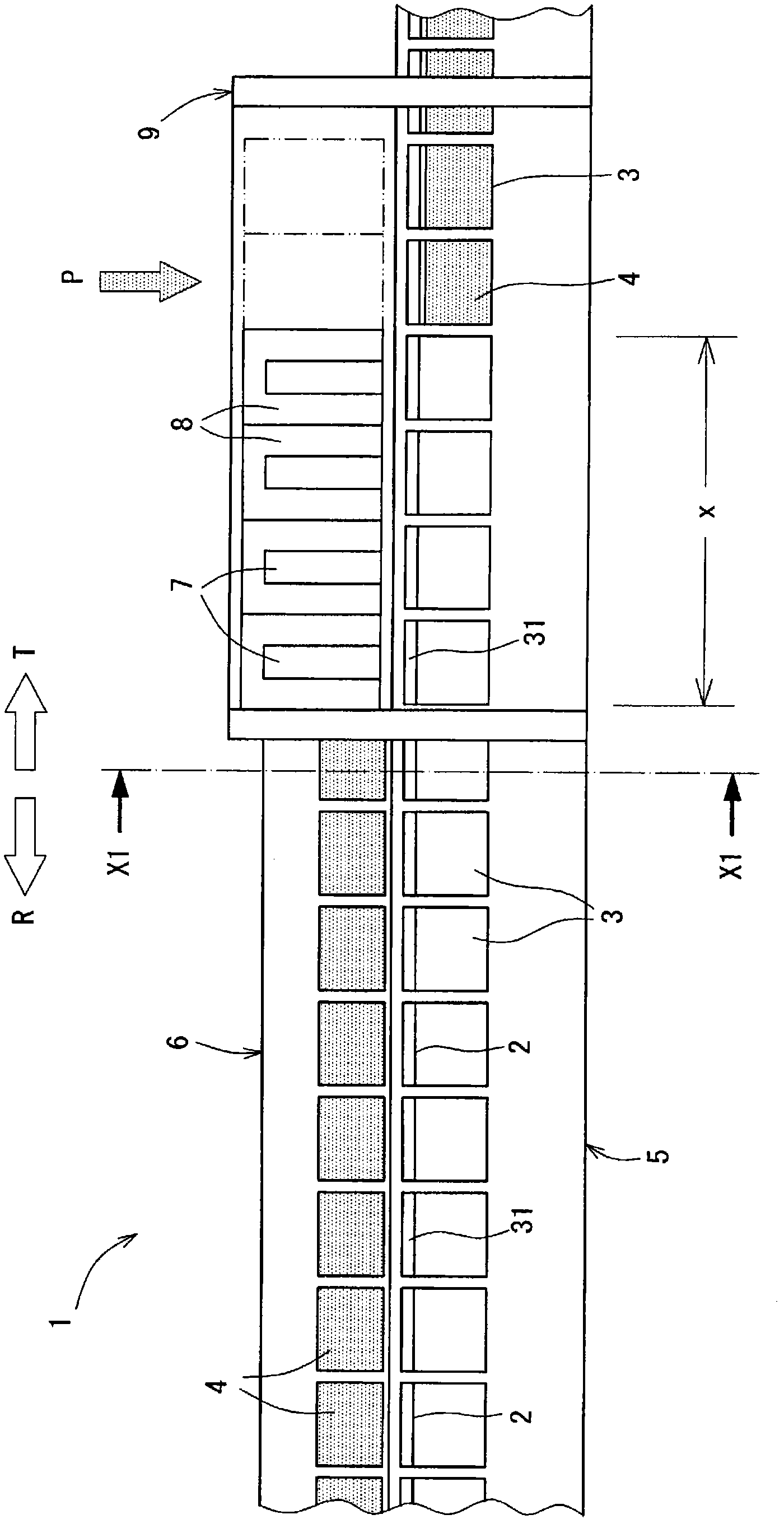

Reciprocating insertion device

An insertion device, reciprocating technology, applied in packaging, paper product packaging, transportation and packaging, etc., can solve the problems of not suitable for the bag body and its contents, and it is difficult to increase the number of contents, and achieve the effect of preventing breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]下述的进给部件或引导部件能够应用周知的技术,因此省略说明或图示上述构件。例如,应用通过使滚珠螺母(ball nut)与进给丝杠螺纹连接而构成的转动副作为进给部件,该进给丝杠与伺服电动机相连接。应用通过使滑块与导轨卡合而构成的滑动副作为引导部件,该导轨沿上述进给丝杠的轴向延伸、或沿气缸的活塞杆(piston rod)的进退方向延伸。

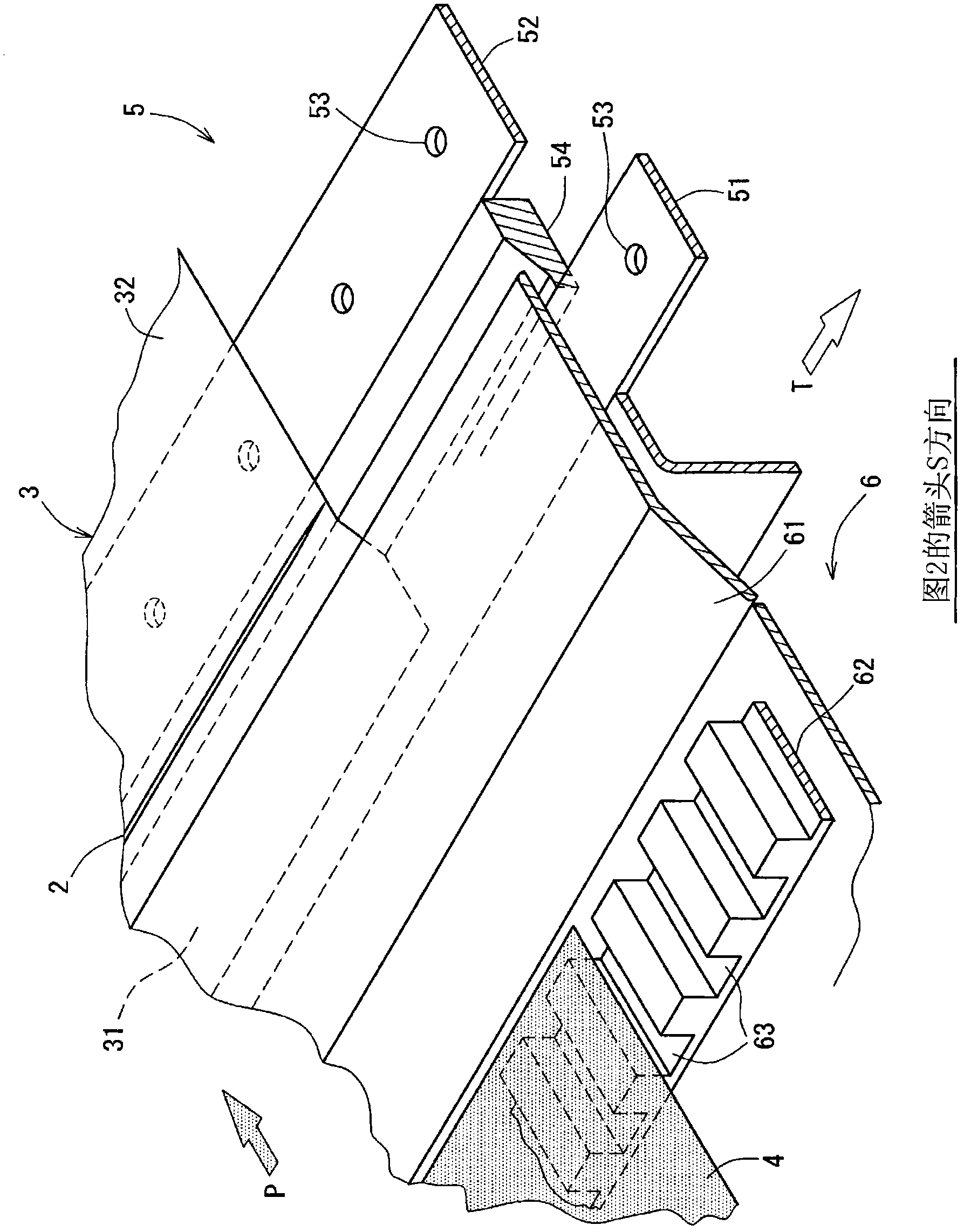

[0034] image 3 From figure 2 的箭头S方向观察输送部件5、移动部件6和设置在输送部件5与移动部件6之间的倾斜板61而得到的立体图。输送部件5具有用于载置袋体3的糨糊涂抹部分31的环形带51、和用于载置袋体3的主体部32的环形带52。在环形带51、52的适当位置上形成有通气孔53,通过将在鼓风机等的吸气口产生的负压引导到通气孔53处,能够将袋体3的糨糊涂抹部分31吸附于环形带51、以及将袋体3的主体部32吸附于环形带52。

[0035] 环形带51比环形带52低,因此被输送部件5输送的袋体3的糨糊涂抹部分31以自开口部2向下方倾斜的方式变形,从而通过倾斜板61的下侧。附图标记54表示用于填补环形带51、52之间的空隙的倾斜型材(bar)。移动部件6是使环形带62沿输送方向行进的带式输送机。移动部件6移动内容物4的速度与输送部件5输送袋体3的输送速度同步。

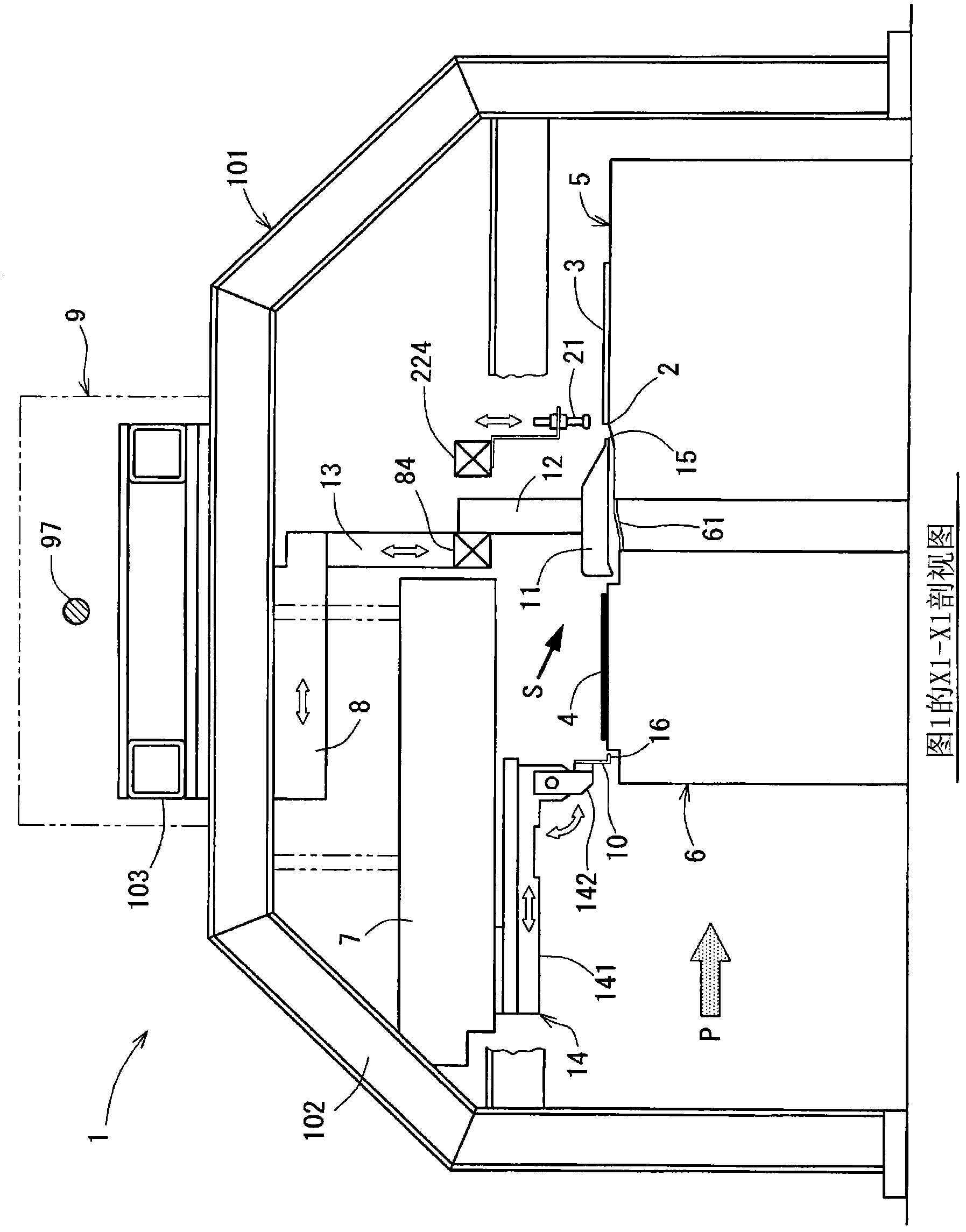

[0036] Figure 4 表示往复式插入装置1的壳体101、进退部件7、进出部件8、往复部件9和转动部件12。 Such as figure 2 所示,壳体101的拱形框架102的上端与水平框架103接合。往复部件9包括可动支承体91、驱动部件92、转动部件12、升降部件13和位移部件14,上述可动支承体91滑动自如地支承于水平框架103,上述驱动部件92用于使可动支承体91沿输送方向移动、或沿与输送方向相反的方向移动。

[0037] Figure 5 means from Figure 4 的箭头X2观察而得到的主视图, Image 6 express Figure 4 的X3-X3剖视图。 Figure 7 表示在可动支承体91的下表面上设置有4个吊架(hanger)93和两个无杆缸(rodless cylinder)81的结构。 Figure 8 表示在进退方向上...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com