Reflecting film for optical information recording medium, and sputtering target for forming reflecting film for optical information recording medium

A recording medium and sputtering target technology, which is applied in the field of sputtering targets, can solve the problems of high noise, reduced crystallite size, and inability to obtain signal quality of optical information recording media of reflective films, and achieves high reflectivity, The effect of reducing noise and improving recording characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

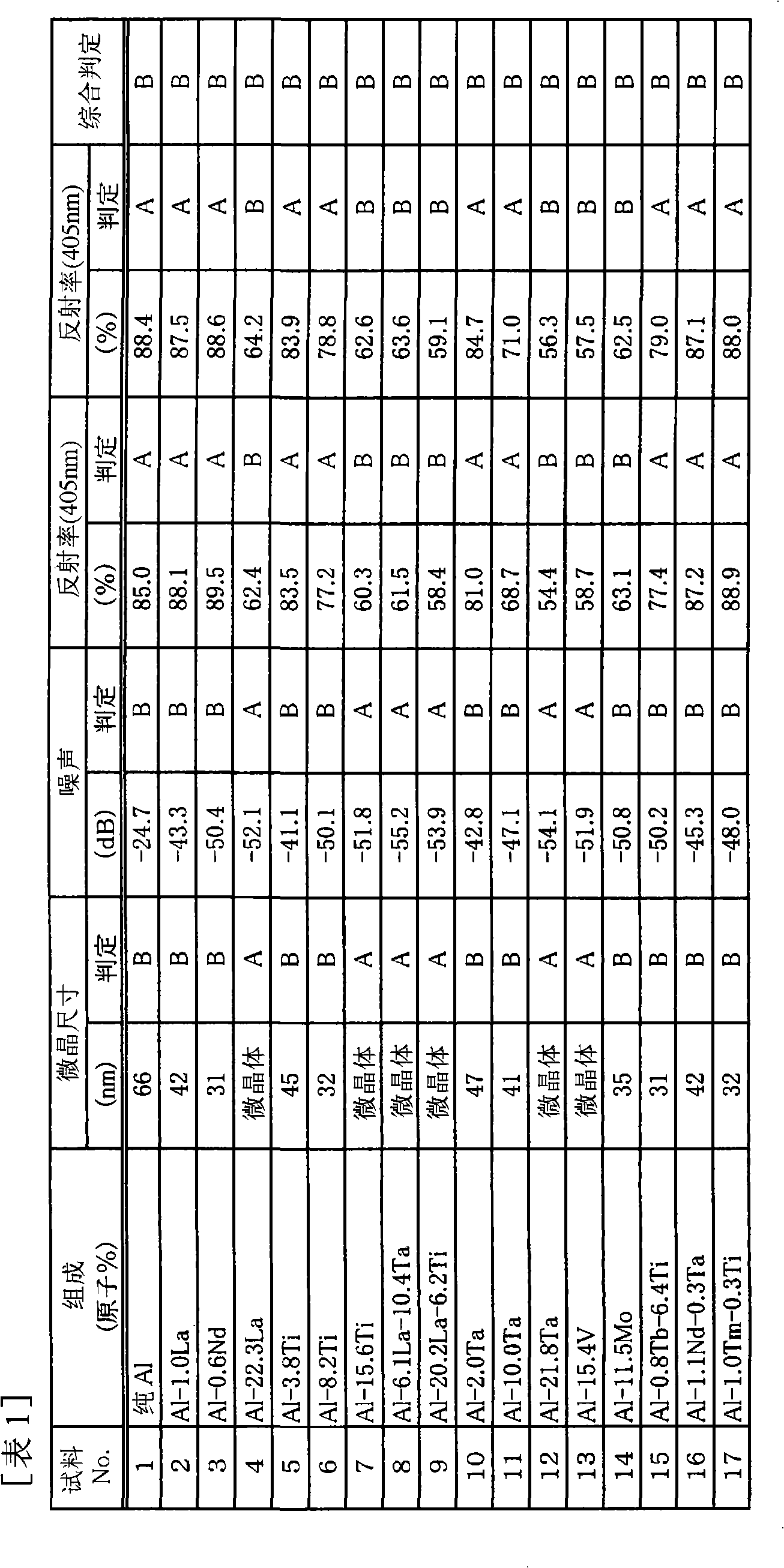

[0041] Hereinafter, examples are given to explain the present invention more specifically, but the following examples do not limit the present invention, but can be appropriately modified within the scope not departing from the spirit of the foregoing and later, and these are included in the present invention. The technical scope of the invention.

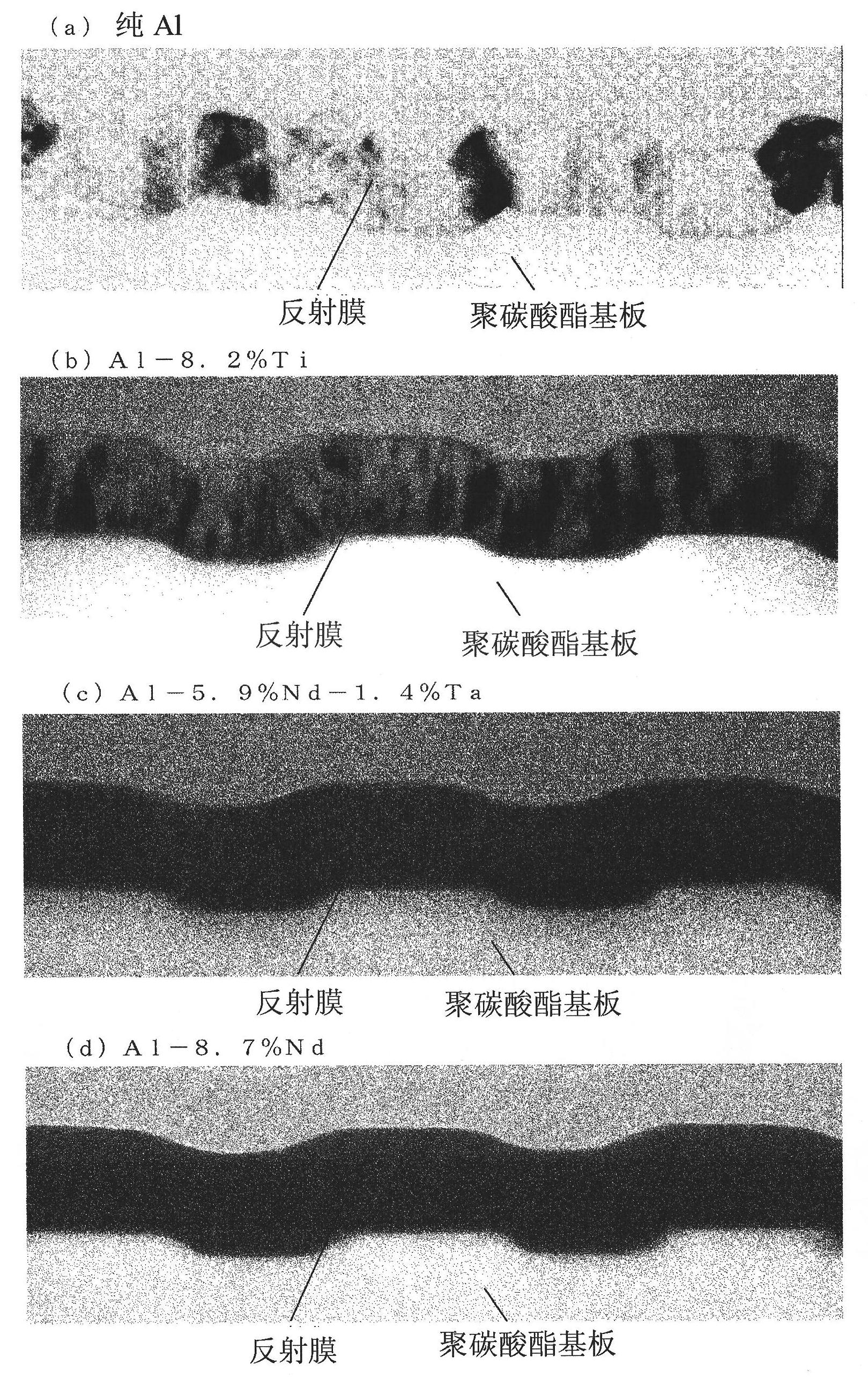

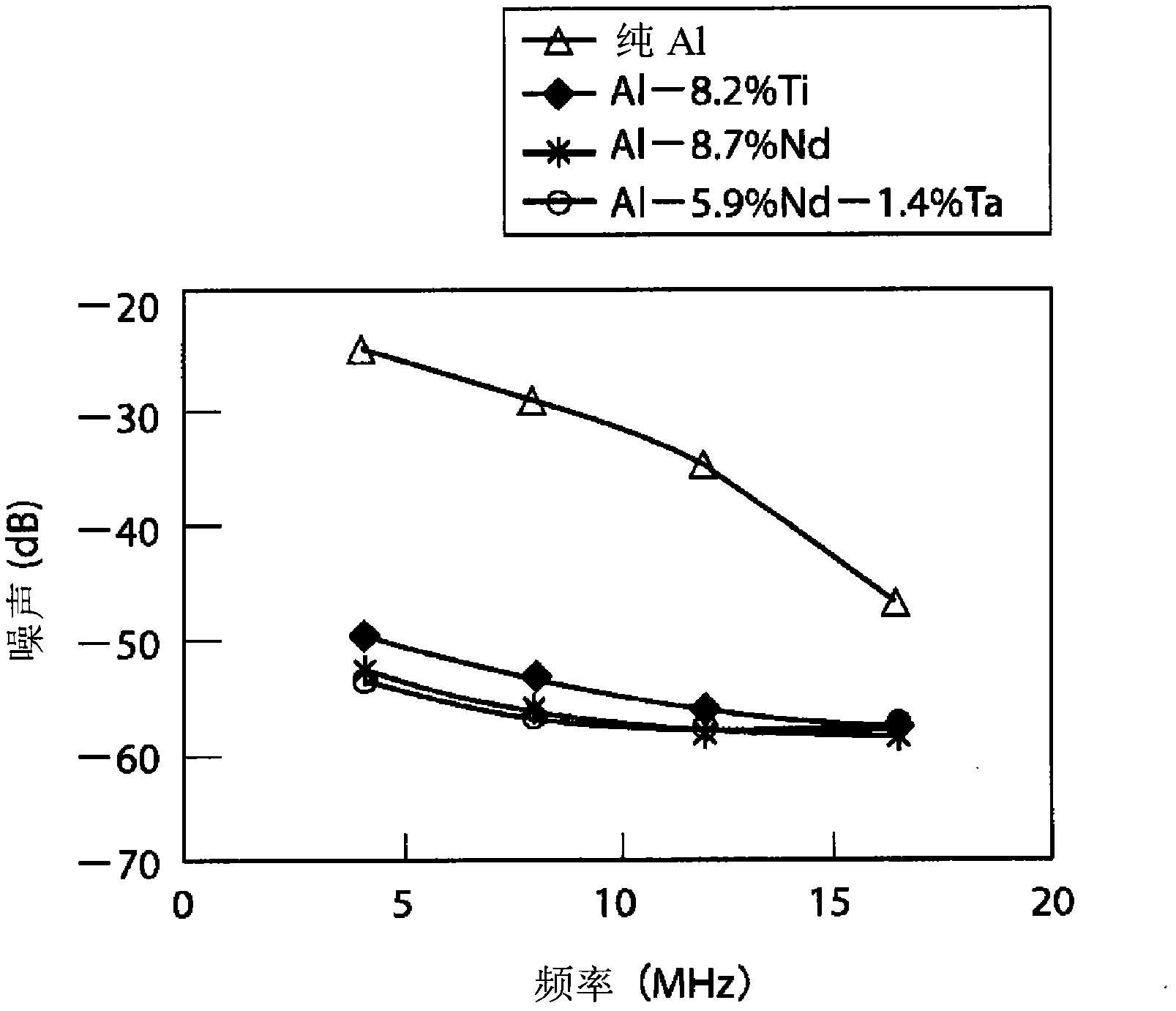

[0042] On a glass substrate or polycarbonate BD-R substrate, use an alloy target or a composite target with an additive element chip placed in a pure Al target, and form various Al-based alloys by DC magnetron sputtering. Film (Tables 1 and 2 will be described later). The sputtering conditions at this time are as follows.

[0043] (Sputtering conditions)

[0044] Sputtering equipment: "SIH-S100" manufactured by Albec

[0045] Target size: φ6 inches

[0046] Reach the vacuum degree: 3.0×10 -6 Torr(4.0×10 -4 Pa) below

[0047] Ar pressure: 3mTorr(0.4Pa)

[0048] Sputtering power: 400W

[0049] The composition of the formed Al-based alloy refle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com