Carbon-nano-tube film and preparation method thereof

一种碳纳米管膜、碳纳米管的技术,应用在碳纳米管、定向碳纳米管、纳米结构制造等方向,能够解决碳纳米管膜透光性影响等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

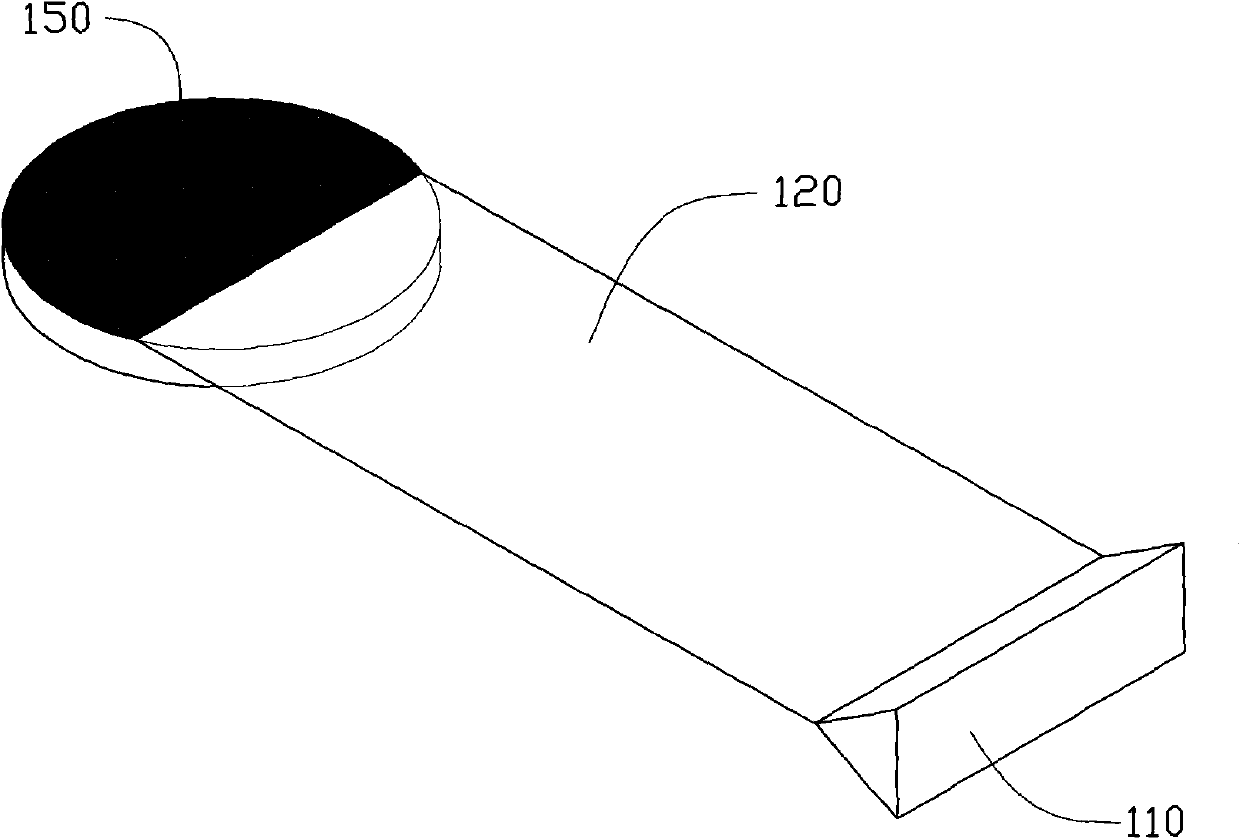

[0036] The embodiment of the present invention provides a method for preparing a carbon nanotube film 100 with better light transmittance, which includes the following steps:

[0037] Step 1: providing a carbon nanotube primary film 120 .

[0038] see figure 1 , the carbon nanotube primary film 120 can be obtained by directly pulling from a carbon nanotube array 150, which specifically includes the following steps:

[0039] (1) A carbon nanotube array 150 is provided.

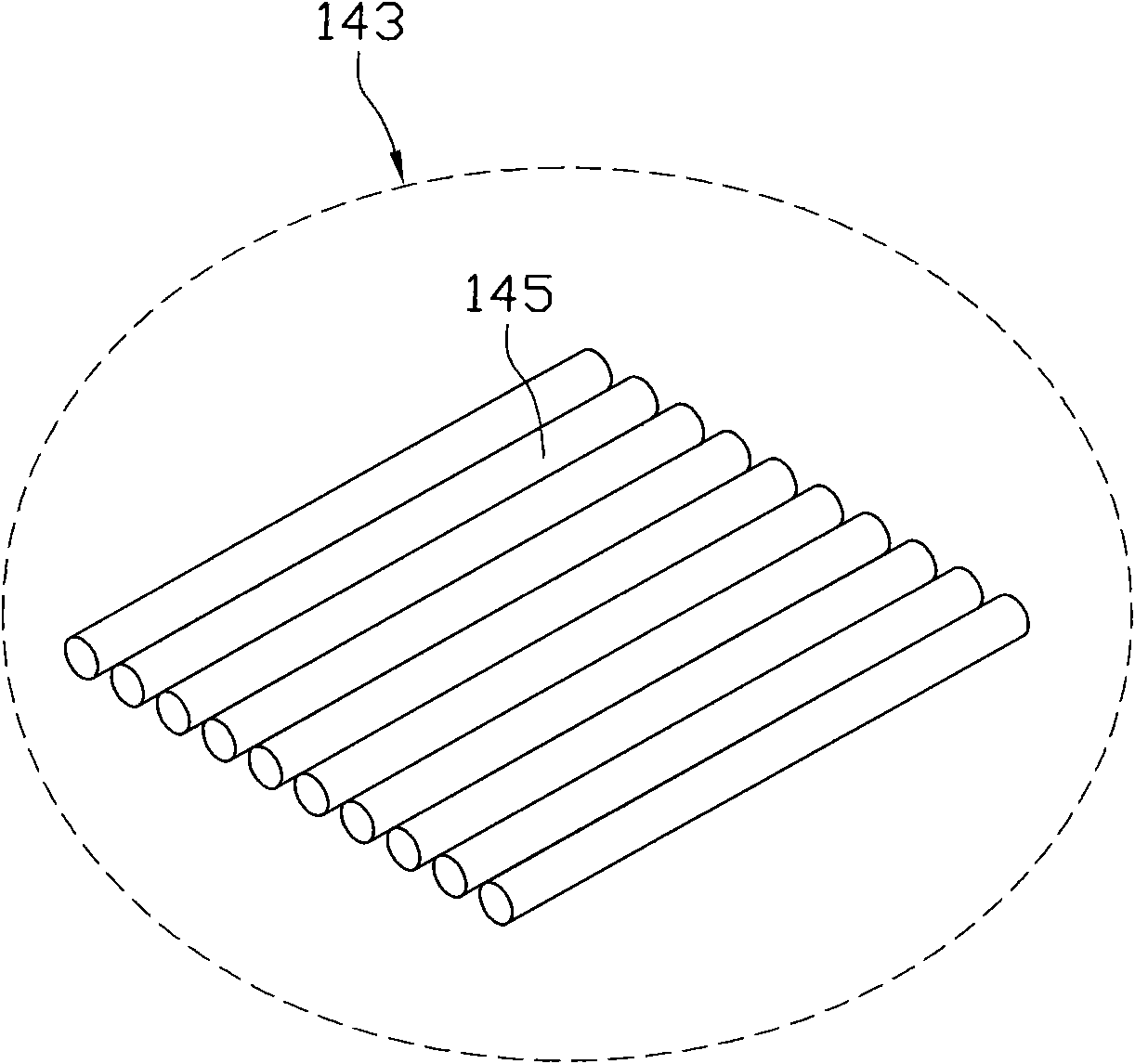

[0040] The carbon nanotube array 150 is formed on the surface of a growth substrate by chemical vapor deposition, preferably a super-aligned carbon nanotube array 150 . The carbon nanotube array 150 includes a plurality of carbon nanotubes substantially parallel to each other and perpendicular to the surface of the growth substrate. By controlling the growth conditions, the carbon nanotube array 150 basically does not contain impurities, such as amorphous carbon or residual catalyst metal particles. For the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com