Wheel type slag crusher

A slag crusher and wheel-type technology, which is used in the removal of solid residues, combustion products treatment, combustion methods, etc., to overcome the increase in bearing load, and to maintain and replace parts easily and conveniently.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

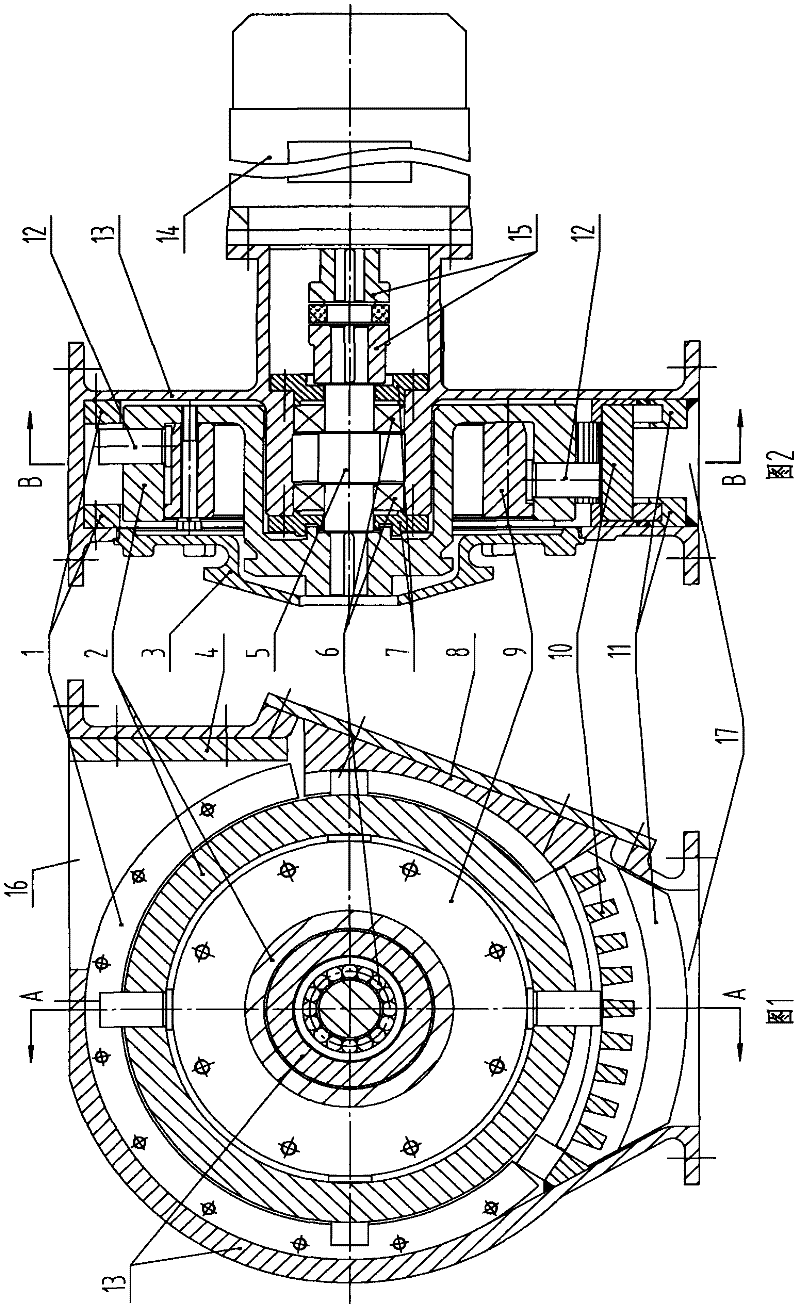

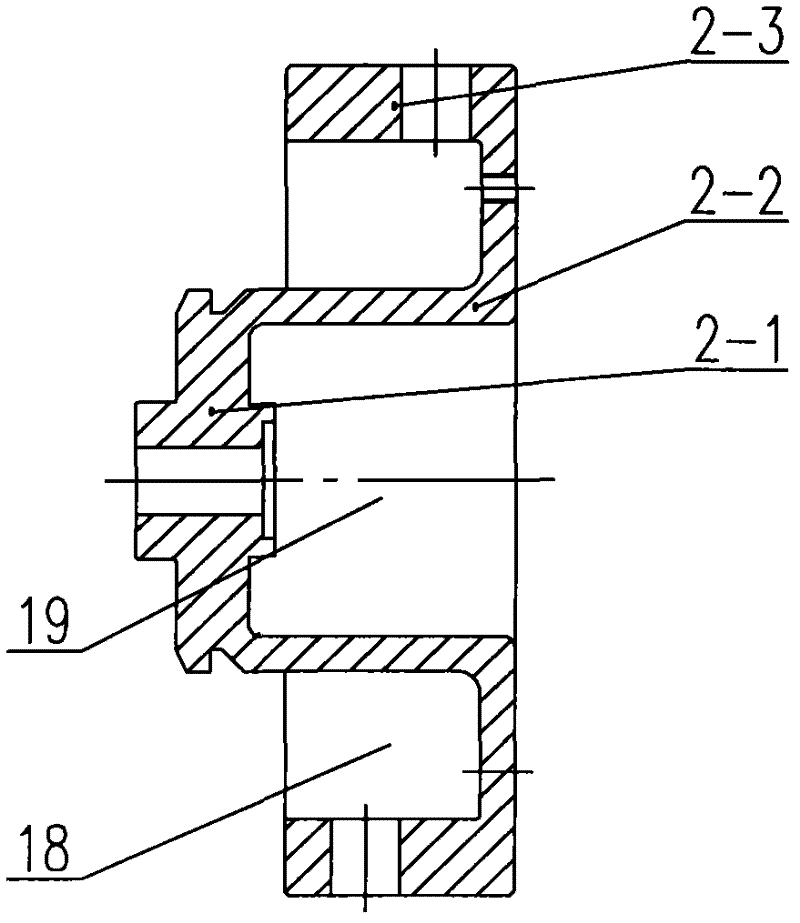

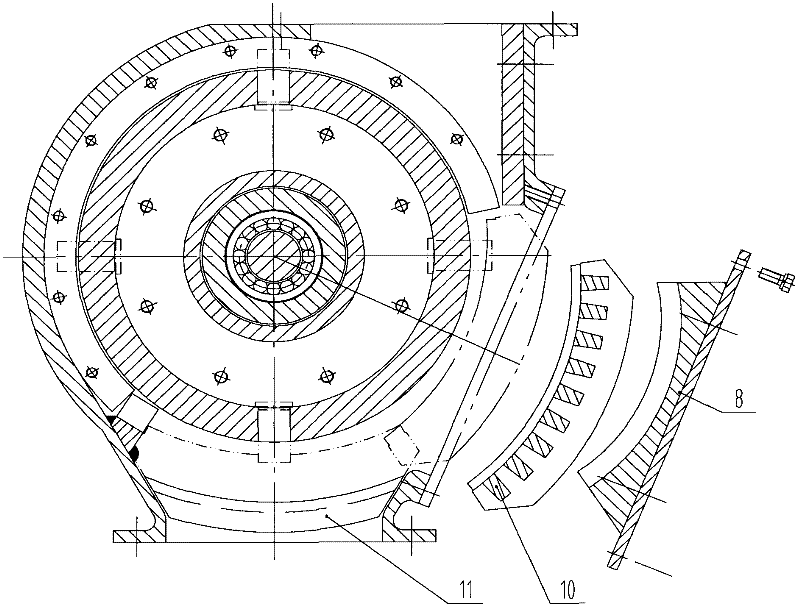

[0029] see figure 1 , figure 2 and image 3 , weld the grate seat 11 to the outlet 17 of the lower part of the casing 13 and install the arc grate 10 with wear-resistant alloy steel grate bars, and then fasten the end liner 1 and the upper side liner 4 to the inner wall of the casing 13 , the end liner 1 occupies about 2 / 3 of the circle, see figure 1 . Assemble the main shaft 5, rolling bearing 6, right end bearing cover 7 and half coupling 15 and add grease, after the main shaft 5 and rolling bearing 6 are installed in the bearing hole of the casing 13, then install the left end bearing cover 7, and tighten the bolts Left and right bearing caps 7. The wheel disc 2 is assembled with its hub 2-1 and one end of the main shaft 5 to form a cantilever structure, and the slag teeth 12 are installed in the cylindrical tooth holes of the wheel rim 2-3 of the wheel disc 2, and the slag teeth 12 are formed by Made of hardened and wear-resistant alloy steel. The spoke plate of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com