Detection line for railway vehicle speed-reducing equipment

A technology for rail vehicles and deceleration equipment, which is applied in the direction of railway vehicle testing, machine gear/transmission mechanism testing, etc. It can solve the problems of strict requirements on the speed of rail vehicles, difficulty in mastering, and affecting detection accuracy, etc., to achieve low equipment investment and accurate speed , easy to promote the effect of the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

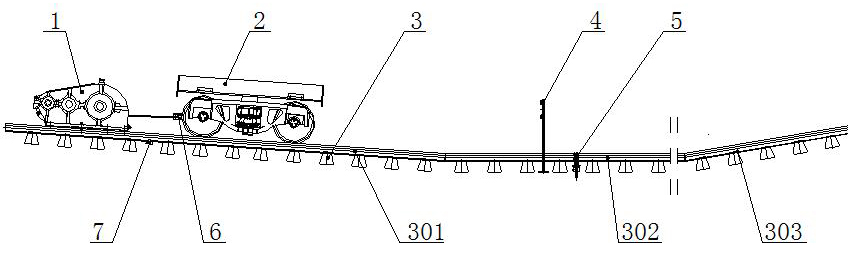

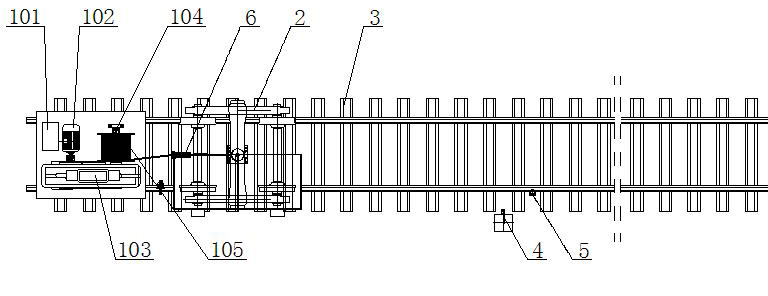

[0028] Example 1: Detection of deceleration tops of rail vehicles

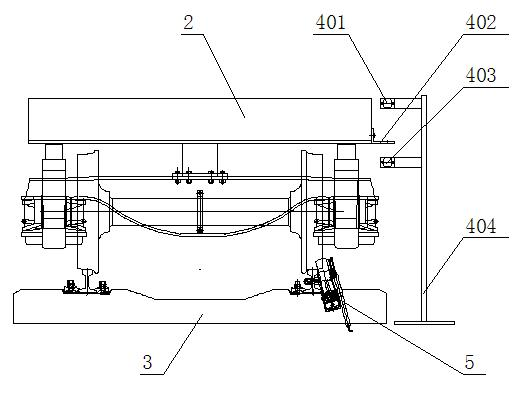

[0029] Such as Figure 1-8 As shown, the hoist 1 is set at the highest point of the acceleration ramp 301, the wheel sensor 7 is set at an appropriate position in the middle of the acceleration ramp 301, the wire rope of the hoist 1 and the test vehicle 2 are connected through the traction buffer 6, and the tested deceleration roof is installed The clamp 5 is arranged on the flat slope section 302 of the track. The tested retarder 801 is fixed to the middle of the rail of the flat slope section 302 through mounting bolts 803 and fastening nuts 804, and the retarder mounting fixture 5 is clamped on the outside of the retarder housing 802 using semicircular clips 511 and fastening bolts 512. A pressure sensor 501 and a displacement sensor 506 are provided on the retarder mounting fixture. The sensor cover 502 of the pressure sensor 501 is located under the retarder housing 802 and connected to the retarder cylinde...

Embodiment 2

[0033] Example 2: Detecting rail vehicle parking device

[0034] Such as Picture 9 As shown, when the braking capacity of the rail vehicle parking device 9 needs to be detected, the tested rail vehicle parking device 9 is installed on the flat slope section 302 of the detection line, and a set of rail vehicle parking device 9 is installed at the entrance and exit. The speed sensor 4 respectively detects the entrance speed and exit speed of the test vehicle 2 passing through the rail vehicle parking device 9, and the braking ability of the tested rail vehicle parking device 9 can be obtained through calculation.

Embodiment 3

[0035] Embodiment 3: Detection of rail vehicle stopper

[0036] Such as Picture 10 As shown, when the braking ability of the rail vehicle stopper 10 needs to be detected, the tested rail vehicle stopper 10 is installed on the flat slope section 302 of the detection line, and a set of speed sensors are installed at the entrance of the rail vehicle stopper 10 4. Detect the speed before the test vehicle 2 collides with the rail vehicle stopper 10. When the rail vehicle stopper 10 is impacted by the test vehicle 2, it will slide along the steel rail, and the braking capacity of the rail vehicle stopper 10 can be calculated by measuring the sliding distance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com