Testing device for crude oil viscosity

A testing device and crude oil technology, which is applied in the pipeline system field, can solve problems such as affecting the enthusiasm of testers, unstable test results, troublesome crude oil cleaning, etc., so that the influence of oil sample shearing history is small, and preparation time is saved. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

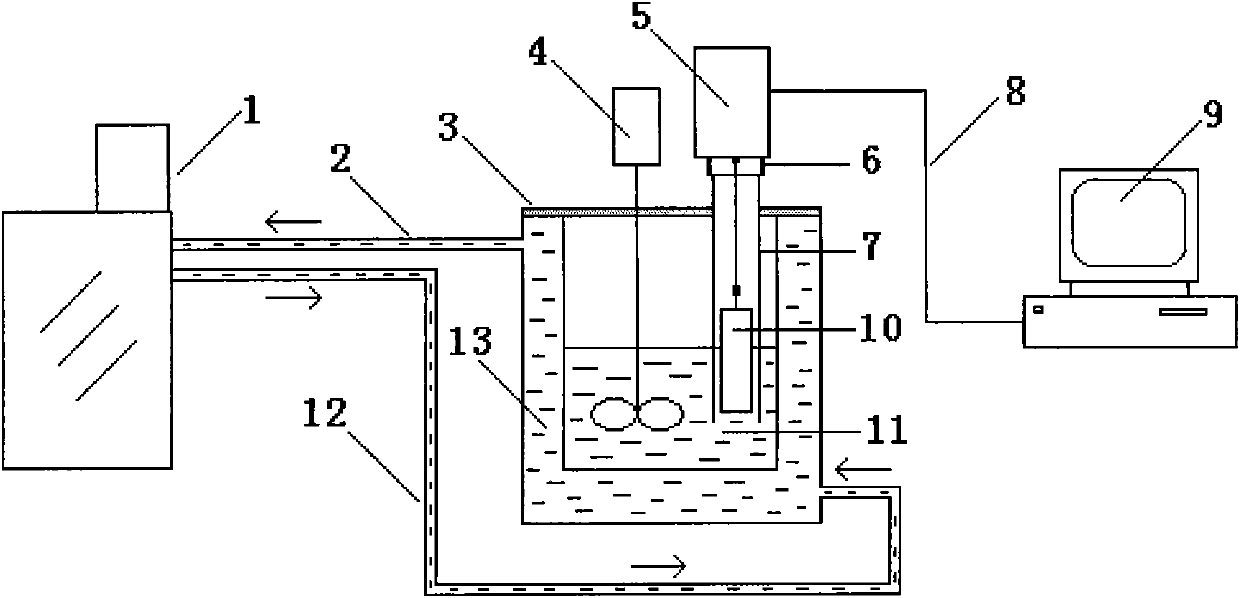

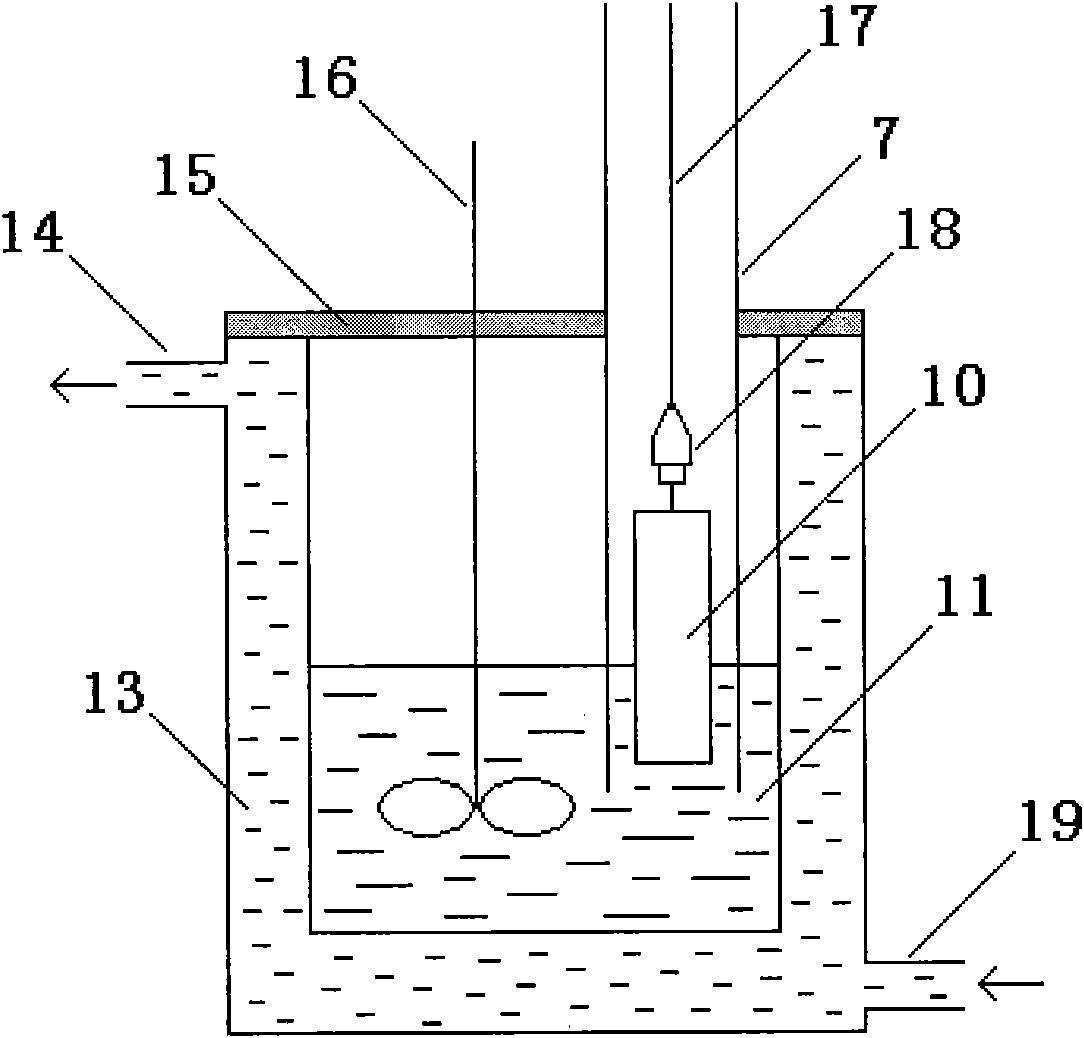

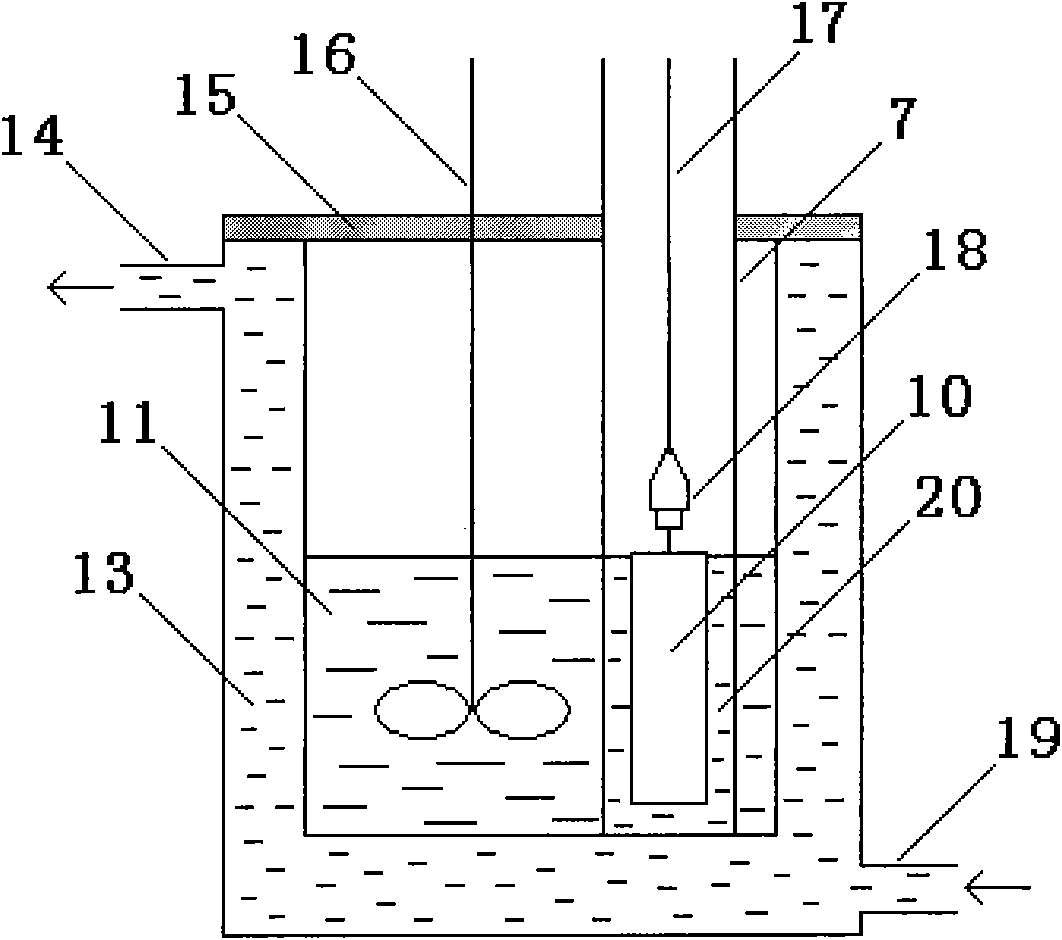

[0046] Embodiment. This example is an experimental prototype, and its constitution is as figure 1shown. It consists of program-controlled water bath 1, water bath inlet pipeline 2, crude oil processing device 3, stirring motor 4, viscometer 5, sleeve connector 6, sleeve 7, data transmission cable 8, computer 9, rotor 10, crude oil 11, water bath Outlet pipeline 12, circulating water 13, water jacket outlet 14, cover 15, stirring paddle 16, rotating shaft 17, rotating shaft connector 18 and water jacket inlet 19. After the program-controlled water bath 1 is connected to the water jacket outsourced by the crude oil treatment unit 3 through the water bath outlet pipeline 12 and the water jacket inlet 19, the water jacket outlet 14 is connected back to the water bath inlet pipeline 2 to control the circulating water in the water jacket of the crude oil treatment unit 3 13 temperature; the upper end is connected to the stirring paddle 16 of the stirring motor 4 through the cover 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com