Microwave cavity and double-waveguide microwave plasma lamp

A plasma lamp and microwave cavity technology, applied in the field of electric light sources, can solve the problems of affecting the lighting effect, unable to emit light, affecting the excitation effect, etc., and achieve the effects of good excitation effect, light weight and low processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

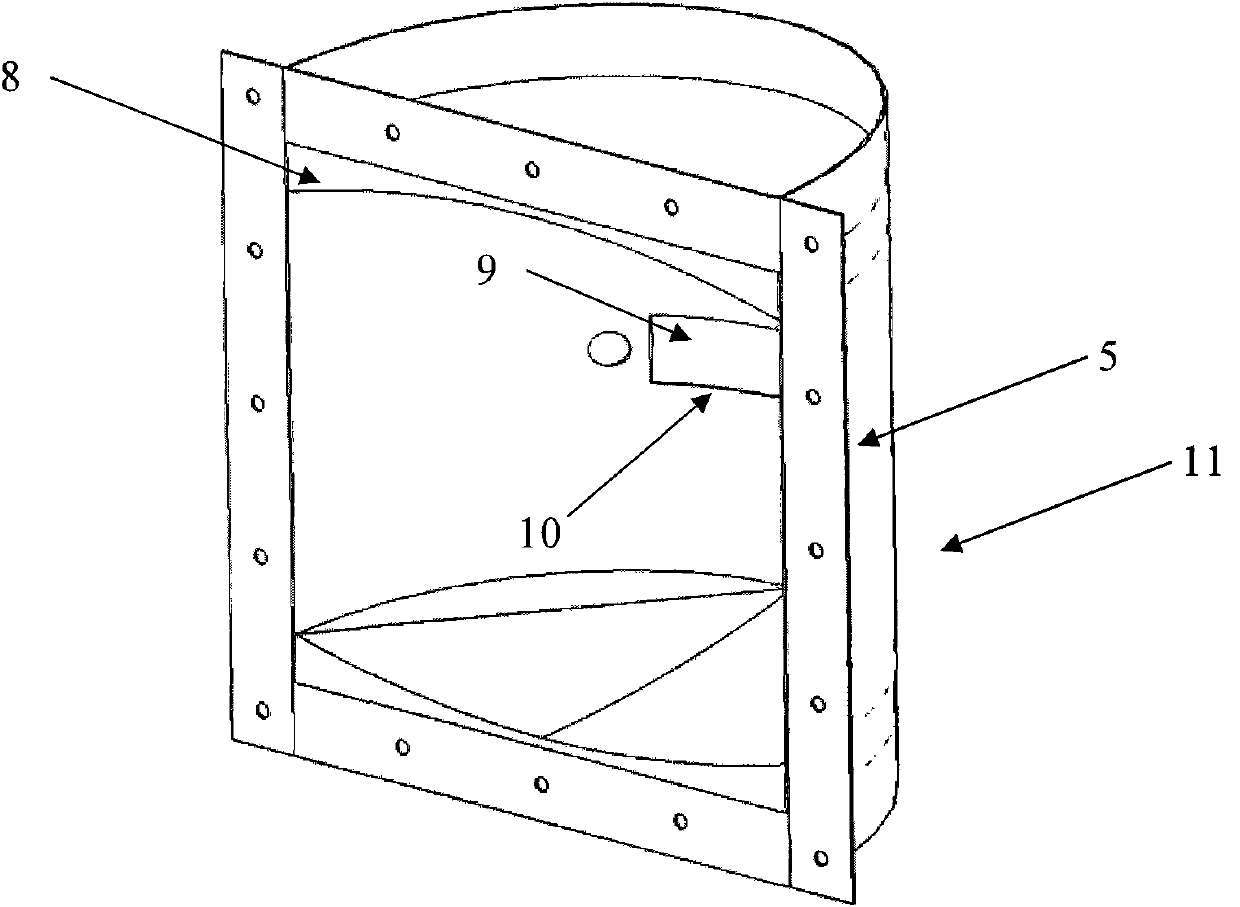

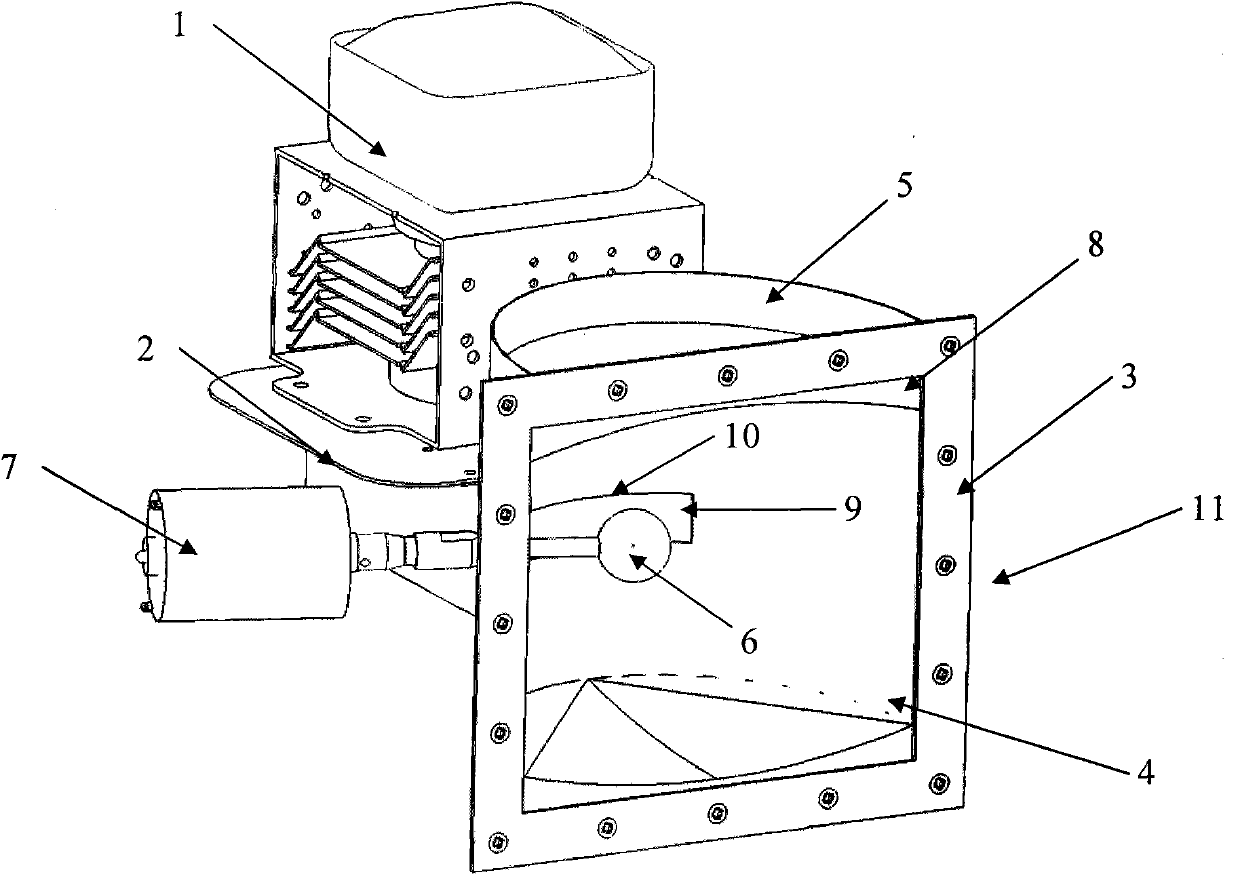

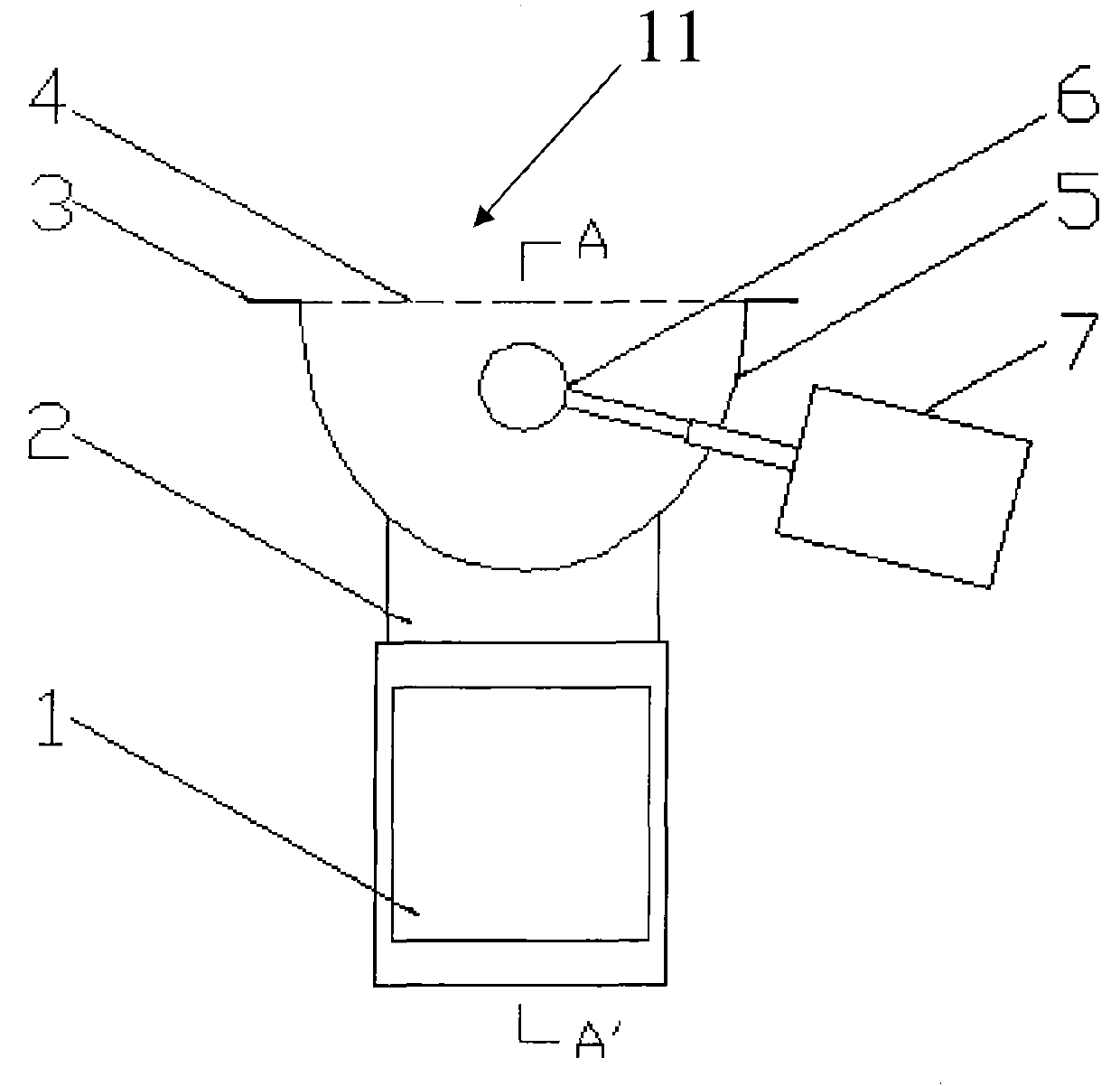

[0031] see figure 1 , a microwave cavity 11 for preventing microwave leakage and emitting the generated light, including: two short circuit boards 8 for preventing microwave leakage and reflecting the generated light; a first waveguide 5 for exciting microwave , to generate light and reflect the generated light; and a metal shielding net 4 to prevent microwave leakage and emit the generated light out of the microwave cavity 11 . The two short circuit boards 8 , the metal shielding net 4 and the first waveguide 5 form a closed cavity. The metal shielding mesh 4 is fixedly connected to the first waveguide 5 through several screws on the flange 3 .

[0032] In this embodiment, the first waveguide 5 is in the shape of a hollow semi-elliptical cylinder. The two short circuit boards 8 are concave mirrors, symmetrically distributed on both sides of the first waveguide 5, and connected to the first waveguide 5 at a certain angle. The angle between the first waveguide 5 and the shor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com