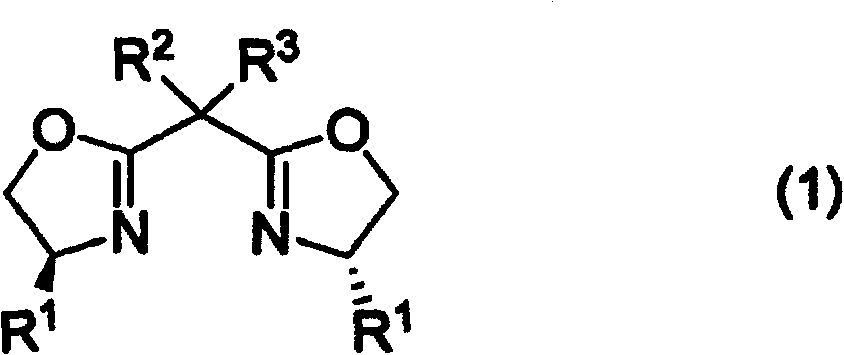

Method for producing (1s,2r)-2-chloro-2-fluorocyclopropanecarboxylic acid

一种氟环丙烷羧酸、氟环丙烷羧酸酯的技术,应用在(1S,2R)-2-氯-2-氟环丙烷羧酸的制造领域,能够解决收率低选择性、不对称等问题,达到高收率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0111] The present invention is described in detail below with reference to Examples. However, the scope of the present invention is not limited to these Examples.

[0112] In the following Preparations and Examples, the yield, anti / syn ratio, cis / trans ratio, optical purity and chemical purity of each obtained product were obtained in the following manner.

[0113] Ethyl diazoacetate

[0114] Yield: Gas Chromatography Analysis

[0115] Column: DB-WAX

[0116] 0.53mm×30m, film thickness is 1.0μm

[0117] (manufactured by Agilent Technologies, Inc.)

[0118] (1S)-Ethyl 2-chloro-2-fluorocyclopropanecarboxylate

[0119] Yield and anti / syn ratio: analysis by gas chromatography

[0120] Column: DB-WAX

[0121] 0.25mm×30m, film thickness is 0.25μm

[0122] (manufactured by Agilent Technologies)

[0123] Optical Purity: Analysis by Gas Chromatography

[0124] Column: InertCap (registered trademark) CHIRAMIX

[0125] 0.25mm×30m, film thickness is 0.25μm

[0126] (manuf...

manufacture example 1

[0157] Manufacturing example 1 : Ethyl diazoacetate

[0158] In a nitrogen atmosphere, 318 g of water, 188 g (1.35 mol) of ethyl glycine hydrochloride and 188 g of n-heptane were sequentially supplied, and the resulting mixture was cooled to 10°C. 1.74 g of a 28% by weight aqueous sodium hydroxide solution was added to the mixture to adjust its pH to 4.7. While keeping the internal temperature at 10±2° C., 279 g of 40% by weight aqueous sodium nitrite solution (net weight: 112 g, 1.62 mol) and 4.54 g (0.0216 mol) aqueous citric acid solution of citric acid monohydrate and 65.8 g of water. The resulting mixture was kept at 10° C. for 6 hours, and an aqueous sodium carbonate solution containing 6.58 g (0.0621 mol) of sodium carbonate and 87.5 g of water was added dropwise to the mixture. While maintaining the internal temperature at 10±5°C, the mixture thus obtained was subjected to liquid-liquid separation. The obtained organic layer was dried using 6.2 g of 4A molecular s...

manufacture example 2

[0159] Manufacturing example 2 : Ethyl diazoacetate

[0160] In a nitrogen atmosphere, 212 g of water, 126 g (0.900 mol) of ethyl glycine hydrochloride and 126 g of n-hexane were sequentially supplied, and the resulting mixture was cooled to 10°C. 1.99 g of a 28% by weight aqueous sodium hydroxide solution was added to the mixture to adjust its pH to 4.9. While keeping the internal temperature at 10±2° C., 186 g of 40 wt % sodium nitrite aqueous solution (net weight: 74.5 g, 1.08 mol) and 3.03 g of ( 0.0144 mol) of citric acid monohydrate and 43.9 g of water in aqueous solution of citric acid. The resulting mixture was kept at 10° C. for 7 hours, and an aqueous sodium carbonate solution containing 4.39 g (0.0414 mol) of sodium carbonate and 58.3 g of water was added dropwise to the mixture. While maintaining the internal temperature at 10±5° C., the thus obtained mixture was subjected to liquid-liquid separation to obtain 213 g of n-hexane solution of ethyl diazoacetate (c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface pH | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com