Single-pas, heavy ion fusion, systems and method

A micro-polymerization and reaction vessel technology, applied in the field of single-pass heavy ion fusion systems, can solve problems such as not being actively explored

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

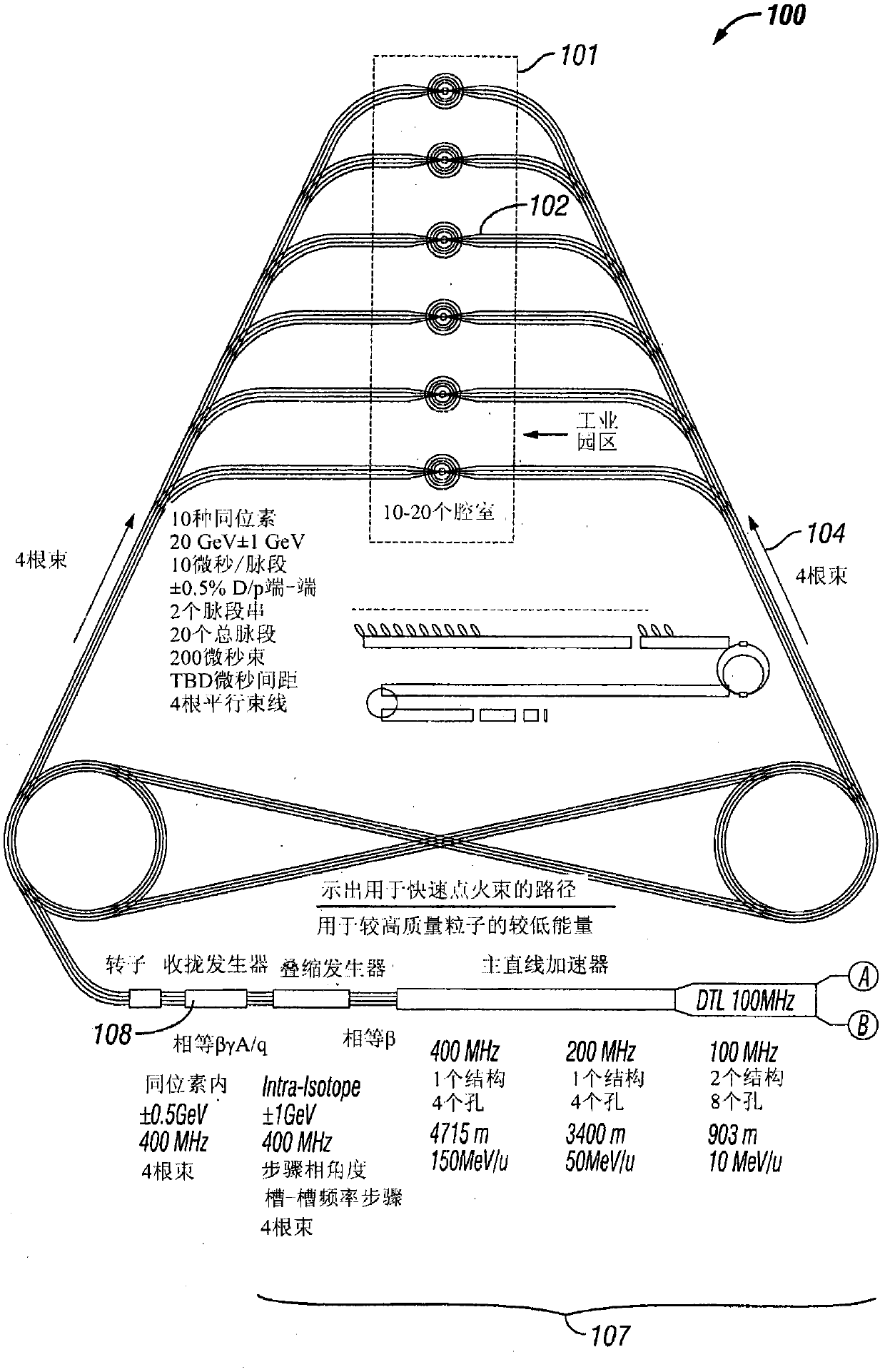

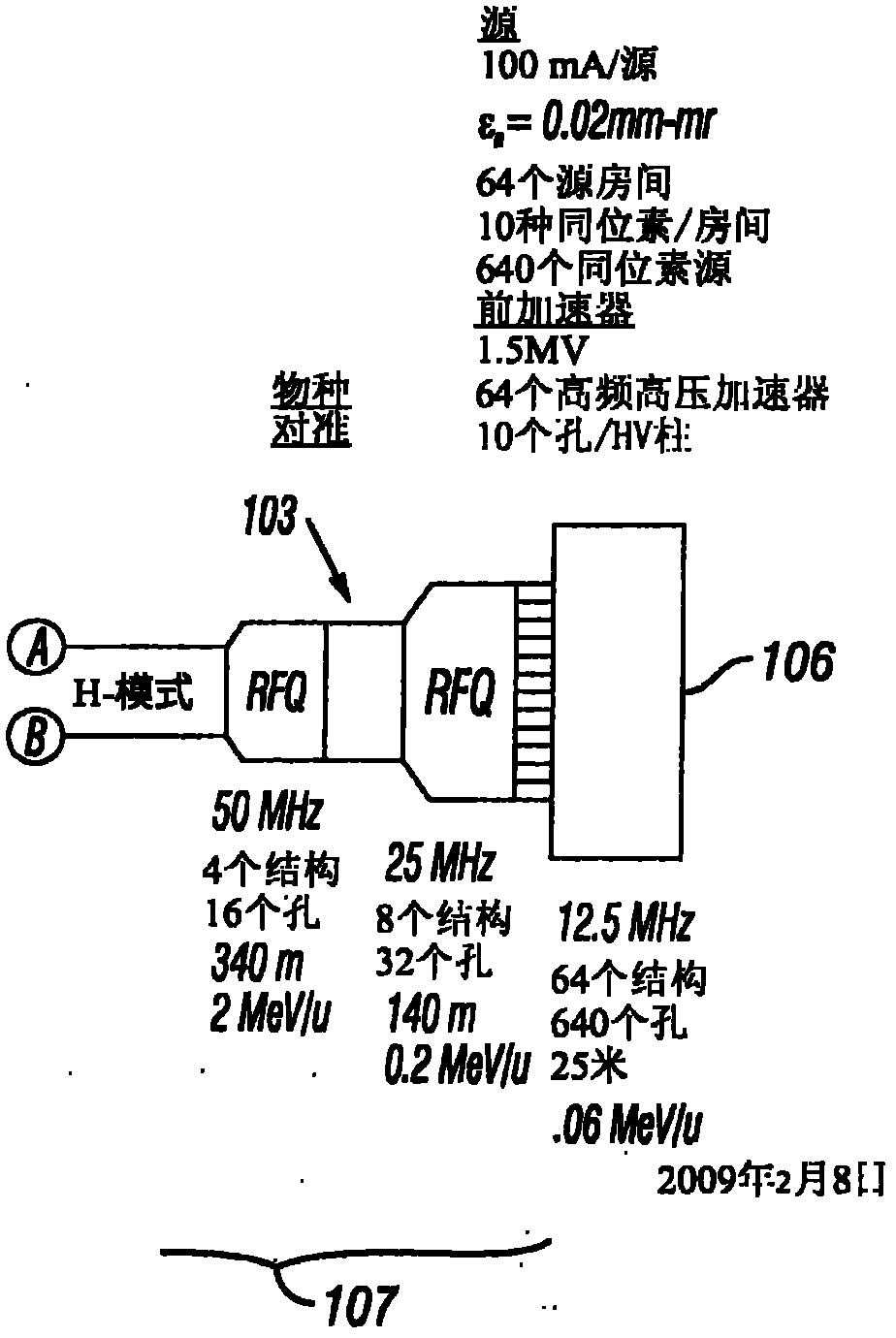

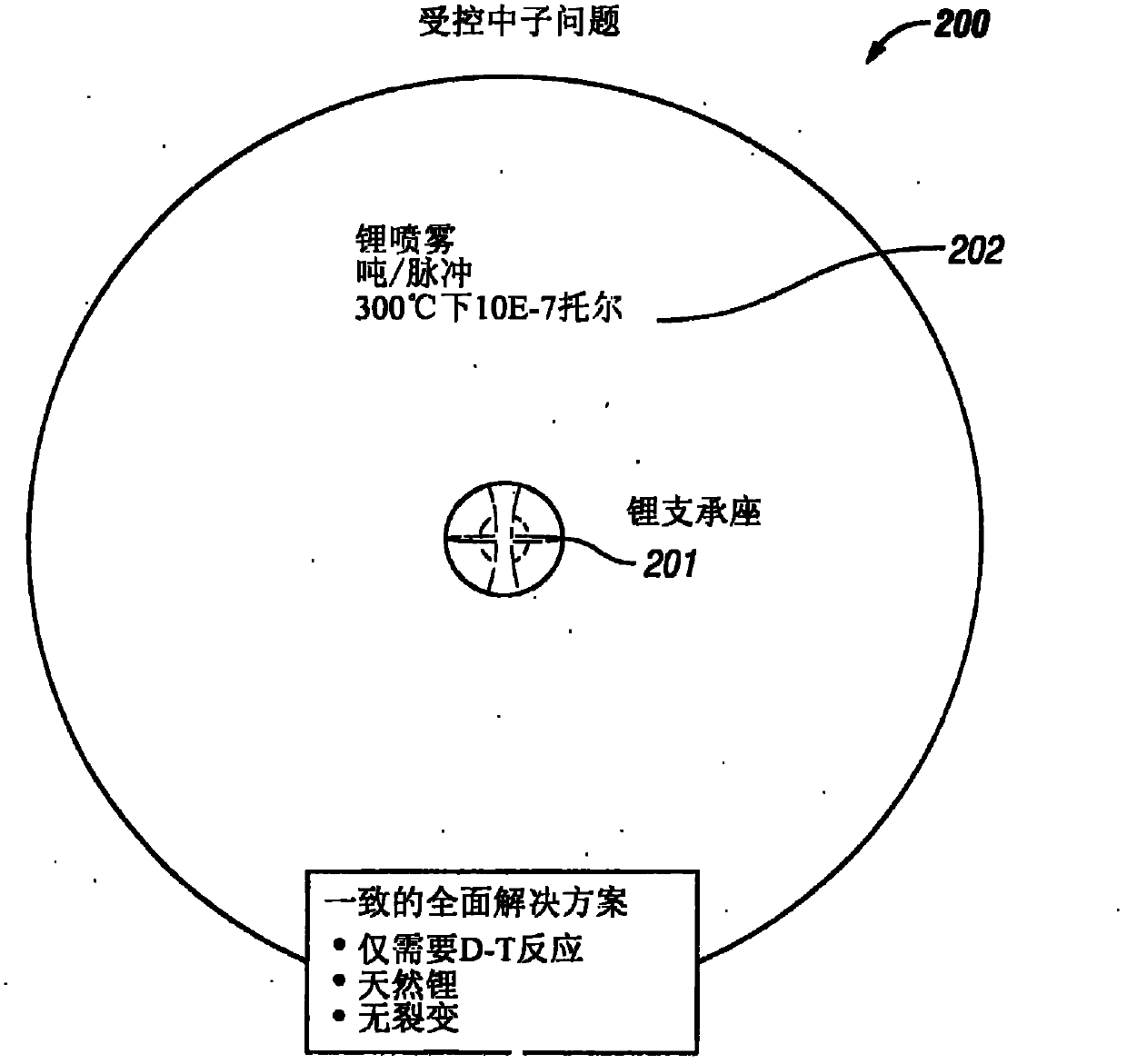

[0046]A single-pass heavy ion fusion system comprising: a new arrangement of current multiplication methods employing multiple sets of isotopes to achieve the desired effect of distributing the task of amplifying current among all the individual processes, thereby relieving stress on any one process, and Increased safety margin to ensure ICF (inertial confinement fusion) power production. The energy and power of the ignition driver pulses are greatly increased, thereby increasing the intensity of target heating and making it easier to obtain reliable ignition. This design eliminates the need for storage rings. A further innovation is to give the HIF (Heavy Ion Fusion) driver the flexibility to drive individual chambers in the most general case where the total distance between the linac output and each of the multiple chambers is different. The use of multiple chambers drastically reduces the proportional capital investment and operating costs per power production unit, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com