Automatic corn haymaking and laying machine

A laying machine and automatic technology, applied to harvesters, cutters, transmissions, etc., to improve operating efficiency, reduce labor costs, and facilitate loading and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

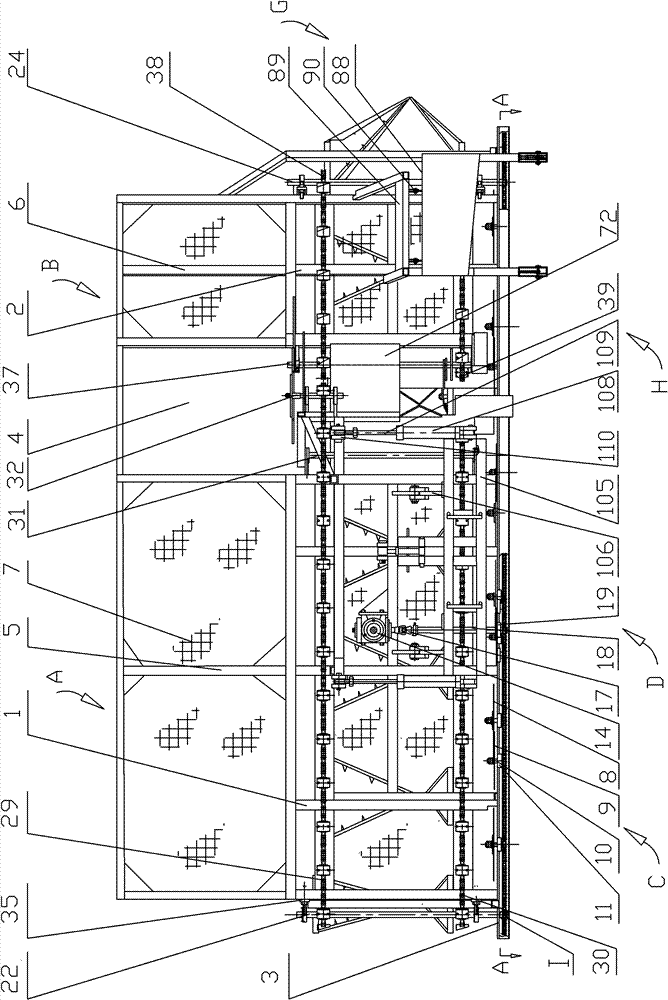

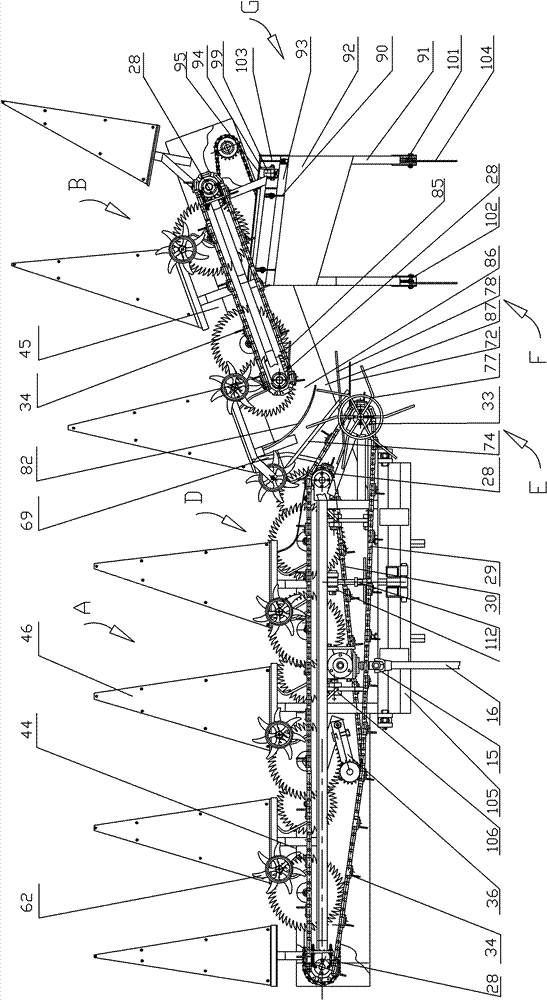

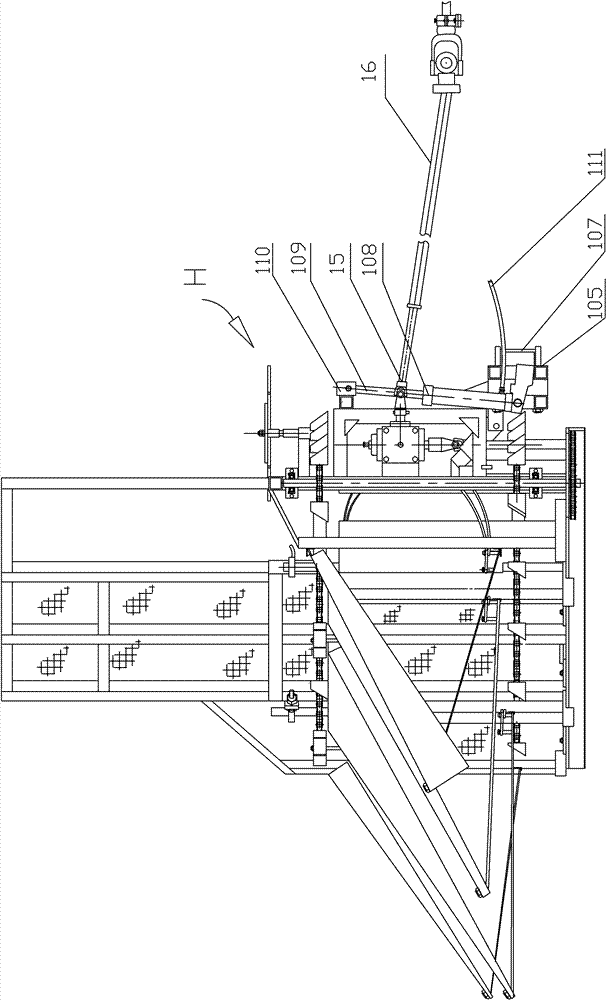

[0027] Referring to Figure 1, figure 2 , image 3 , Figure 4 , Figure 5 As shown, a corn cutting and drying automatic laying machine is mainly composed of a main frame assembly A, an auxiliary frame assembly B, a cutting device C, a transmission device D, a supporting device E, a transfer escort device F, and an automatic laying machine with horizontal poles. G and lifting device H are composed of eight parts; the main frame assembly A and auxiliary frame assembly B are respectively connected to the left and right ends of the base 3 of the cutting device C, and the main frame assembly A is connected to the auxiliary frame assembly through the transmission device D B. The two ends of the side base 3 of the main frame assembly A and the sub-frame assembly B are respectively provided with a supporting device E, and a lifting device H is arranged in front of the main frame assembly A. In the sub-frame assembly B is provided with a transfer escort device F, and the front end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com