Wafer spray cleaning method

A technology of wafers and nozzles, which is applied in the field of wafer spray cleaning and wafer cleaning, and can solve the problems of reduced cleaning efficiency and affecting output rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

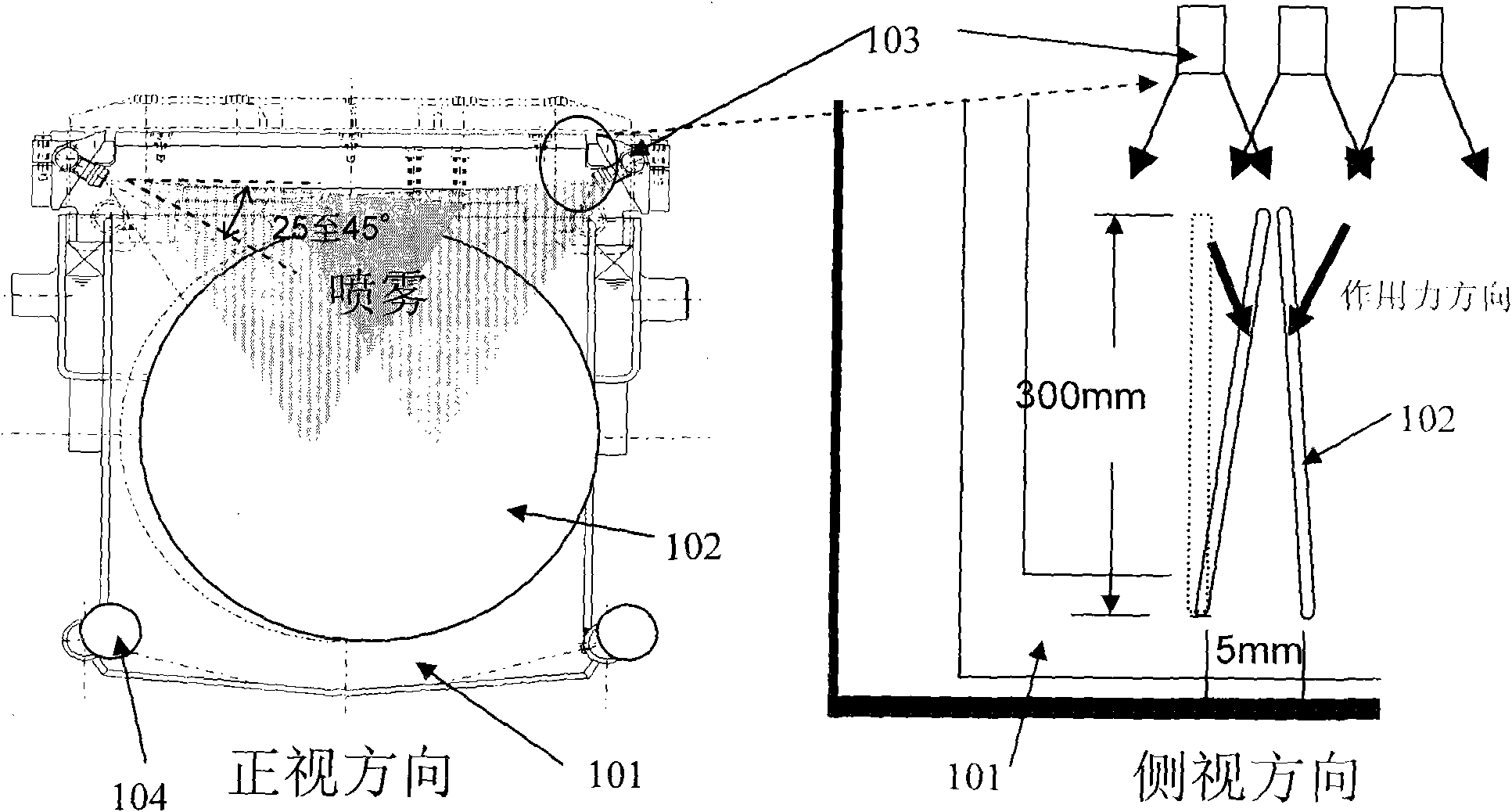

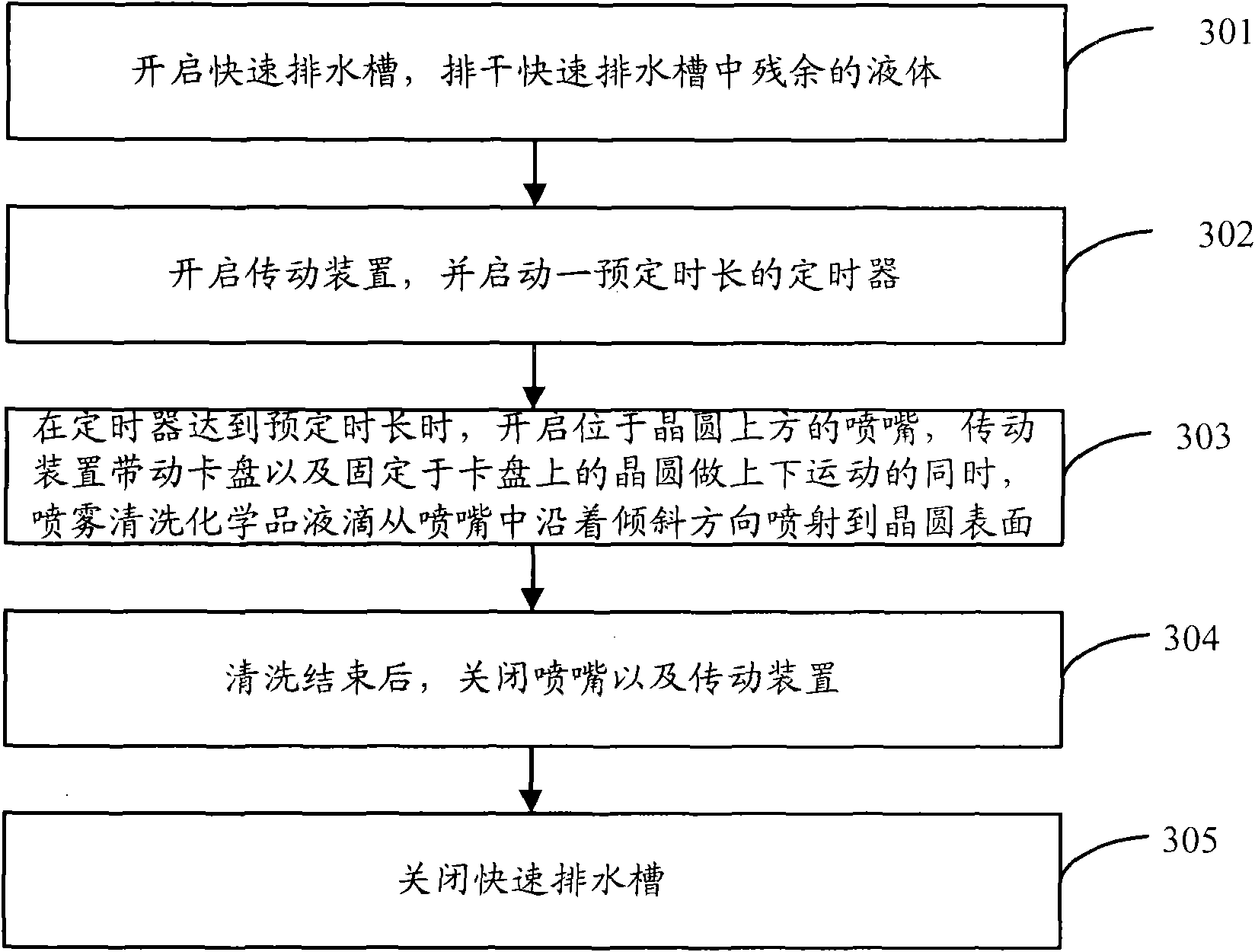

[0024] The object of the present invention is to keep the distance between the wafers at 5 mm, so that the swing range of the wafers during the spray cleaning process is small enough so that adjacent wafers do not contact. According to the previous analysis, the liquid droplets ejected from the nozzle exert a force on the wafer, and the moment of this force relative to the fixed point of the wafer is the root cause of the swing of the product circle. It is therefore the object of the present invention to actually reduce this moment.

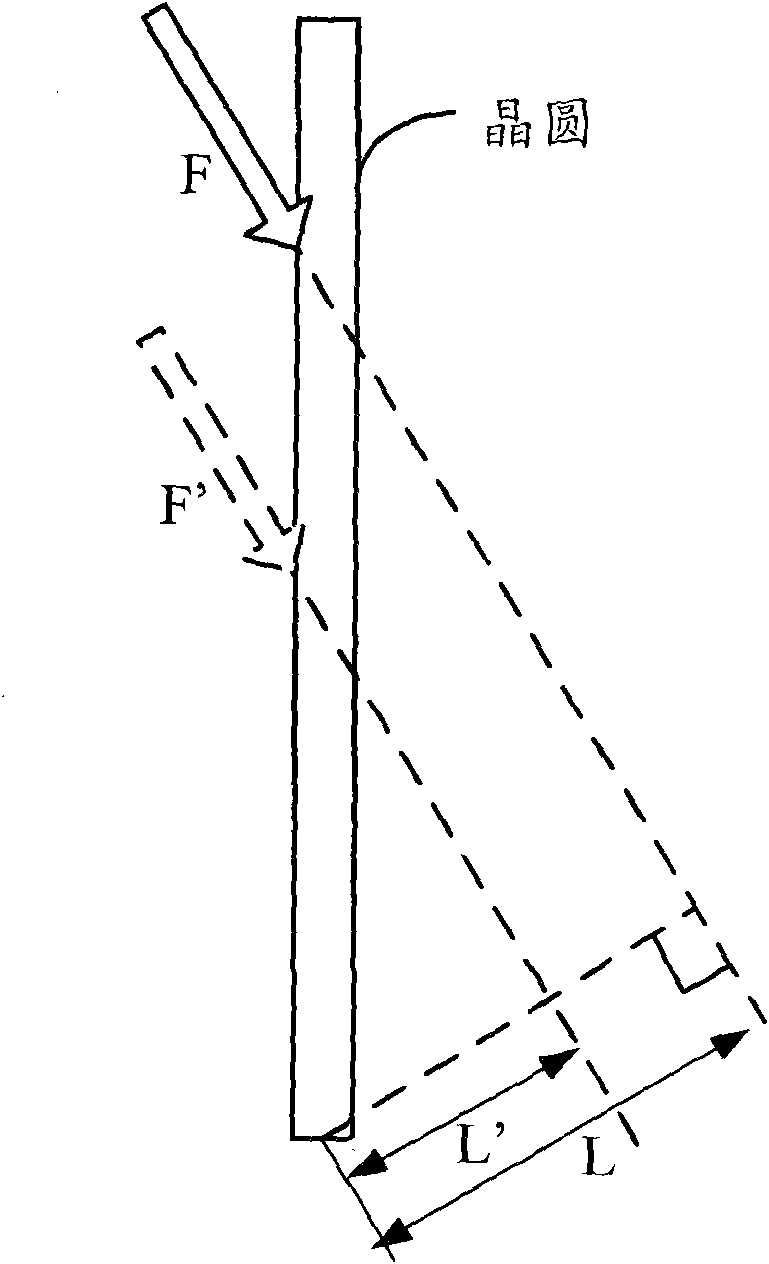

[0025] According to the physical definition of torque: torque M=L×F, where F is the force, L is the distance from the point of action of F to the axis of rotation, figure 2 It is a schematic diagram of the wafer being subjected to the droplet force during the spray cleaning process. From figure 2 It can be seen intuitively that to reduce the moment M, the options available include:

[0026] (1), reduce the size of the force F. The force F i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com