Held tip mechanism

A clamping, top-end technology, which is applied in the direction of clamping, tool holder accessories, metal processing machinery parts, etc., can solve the problems of the single top of the tail vertebra being easily damaged, large vibration, easy to produce overcut, etc., and achieve firm positioning , Anti-vibration, not easy to damage the effect

Inactive Publication Date: 2011-06-15

WUXI AIERFU BLADE

View PDF4 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

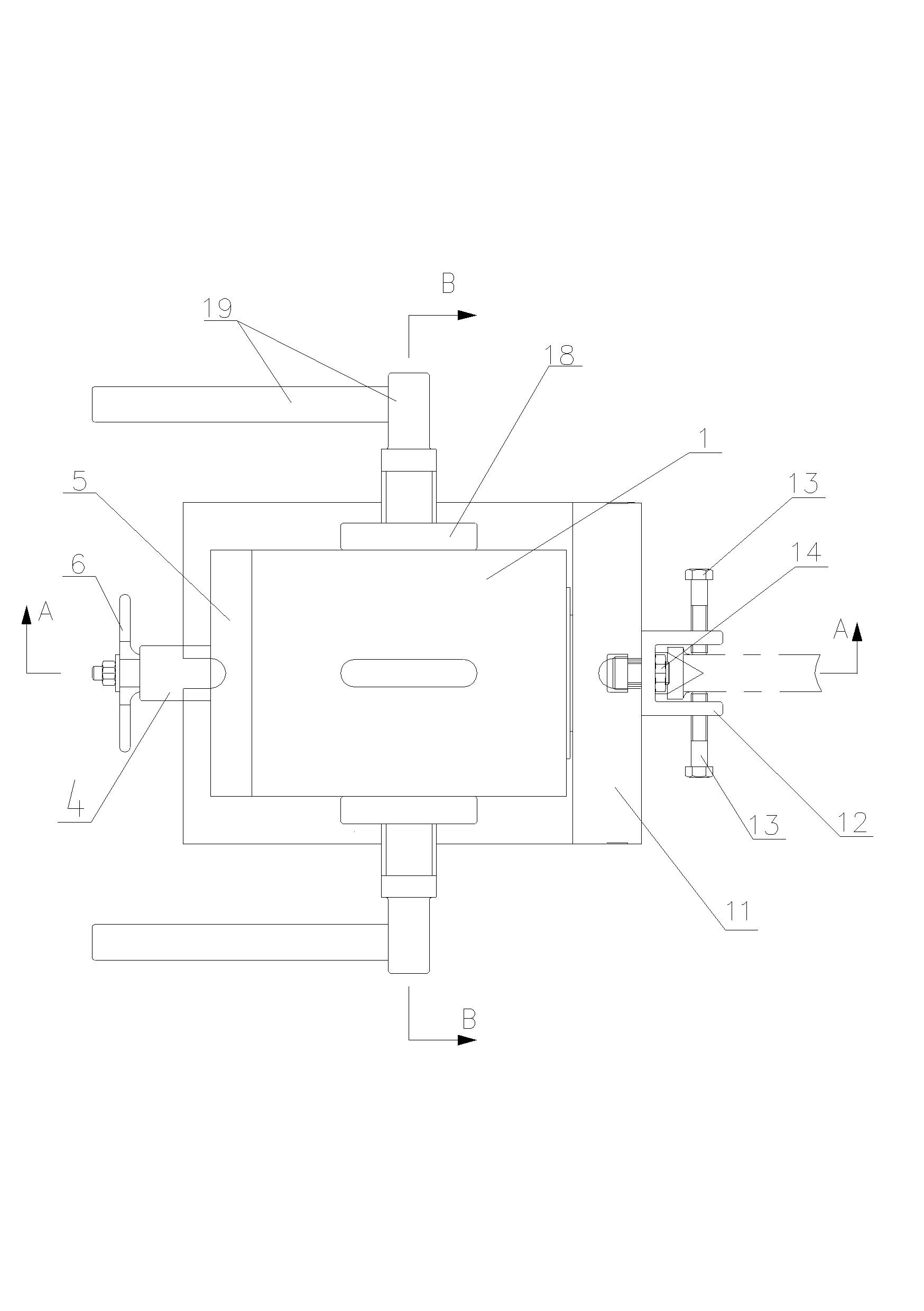

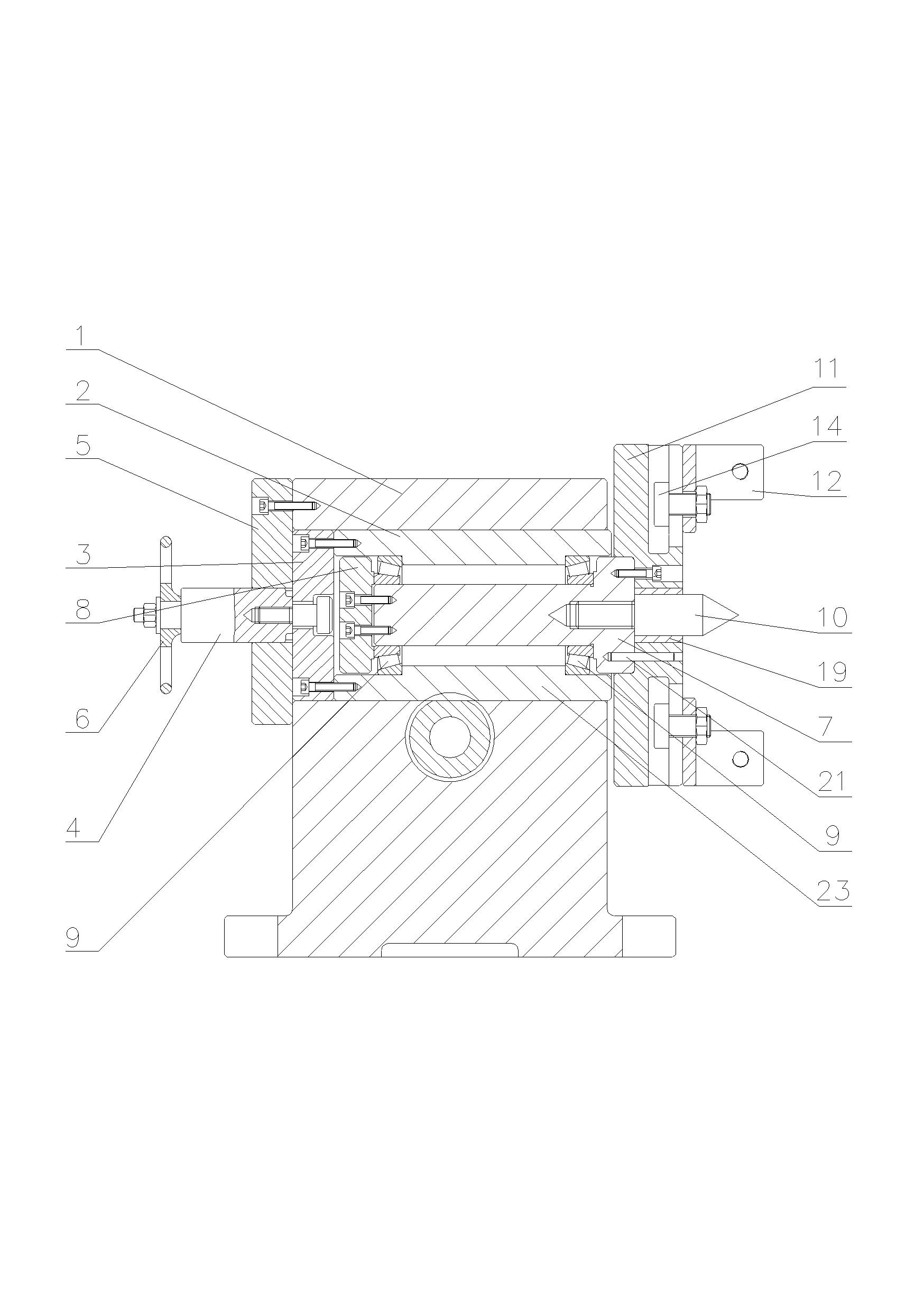

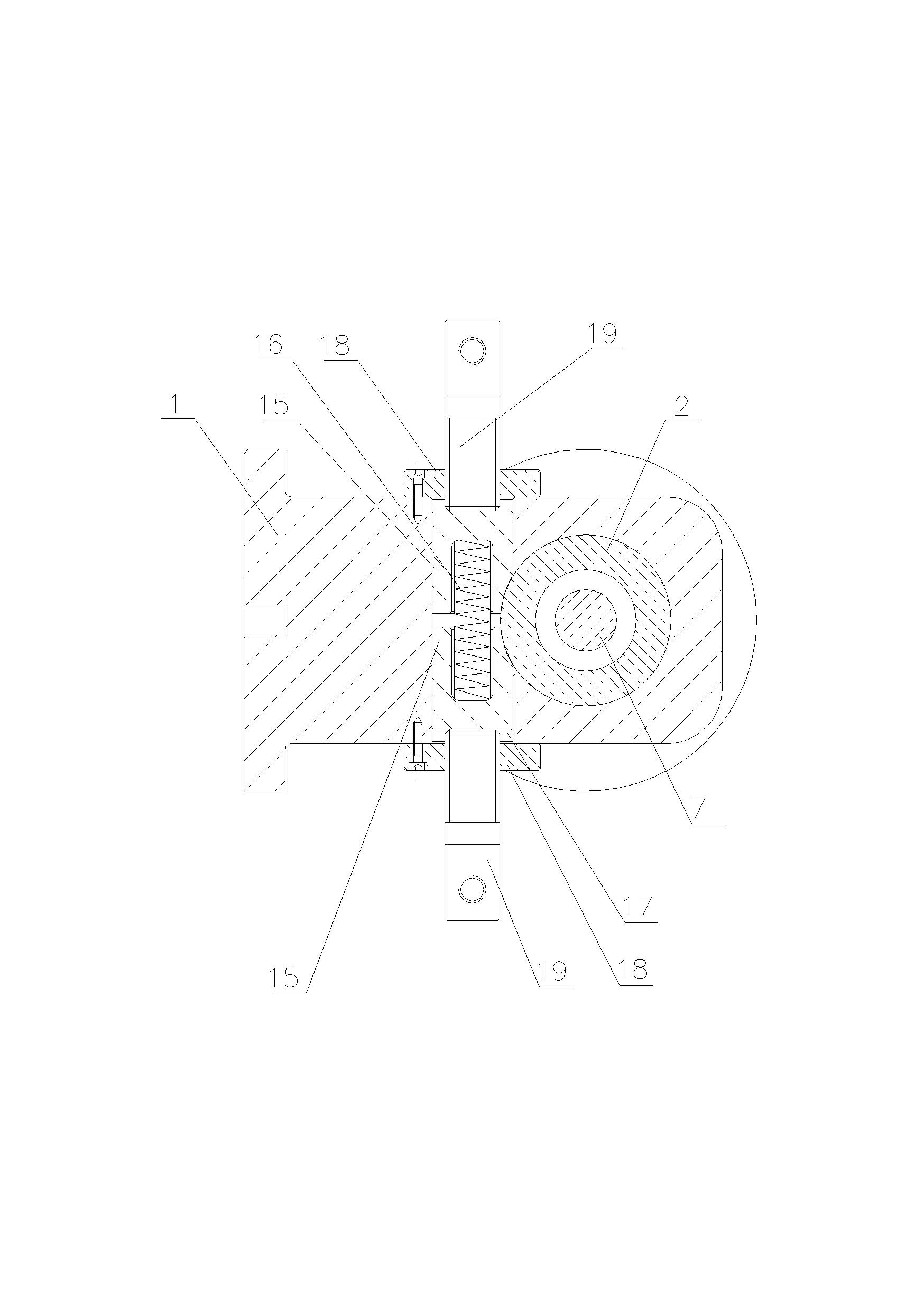

The invention provides a held tip mechanism, and relates to the technical field of processing of gas turbine blades. The held tip mechanism effectively prevents vibration of the blades, and does not generate over cutting phenomenon so that the single tip of the caudal vertebra is not easily damaged. The held tip mechanism comprises a base and a rotary shaft sleeve, wherein the rotary shaft sleevetransversely passes through the base, the tail end of the rotary shaft sleeve is connected with a hand wheel, and the front end of the rotary shaft sleeve is connected with a tip. The held tip mechanism is characterized in that: a rotary disc is sleeved on the external circular face of the tip, the circle center of the rotary disc is positioned on the central line of the tip, and clamping frames are fastened at two ends of the same diameter of the rotary disc.

Description

Clampable top mechanism technical field The invention relates to the technical field of steam turbine blade processing, in particular to a clampable tip mechanism. Background technique The steam turbine blade profile is a twisted profile. The blade profile is usually processed by three center holes for positioning, two center holes for the root, and one center hole for the top. With the development of technology, the width of the blade profile of the unit is getting larger and heavier, which brings certain difficulties to the CNC rotary machining and clamping of the blade profile. In the actual production process of the blade, two problems arise. Problem 1: The tip of the blade enters and exits the steam side, and the vibration is large during processing, which is prone to overcutting; Problem 2: Due to the heavy blade, the original single tip of the tail vertebra of the machine tool is easily damaged. Contents of the invention In view of the above problems, the pres...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23B33/00B23Q3/06

Inventor 张国新

Owner WUXI AIERFU BLADE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com