Processing technique for heavy crankshaft and shaft part milling frame stations and technique equipment

A technology of shaft parts and processing technology, applied in the field of heavy crankshaft and shaft parts rack processing, can solve the problems of poor rack surface quality, high cost, small load-bearing tonnage of machine tools, etc., to improve product quality and competitiveness, The effect of simplifying the machining process and improving the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

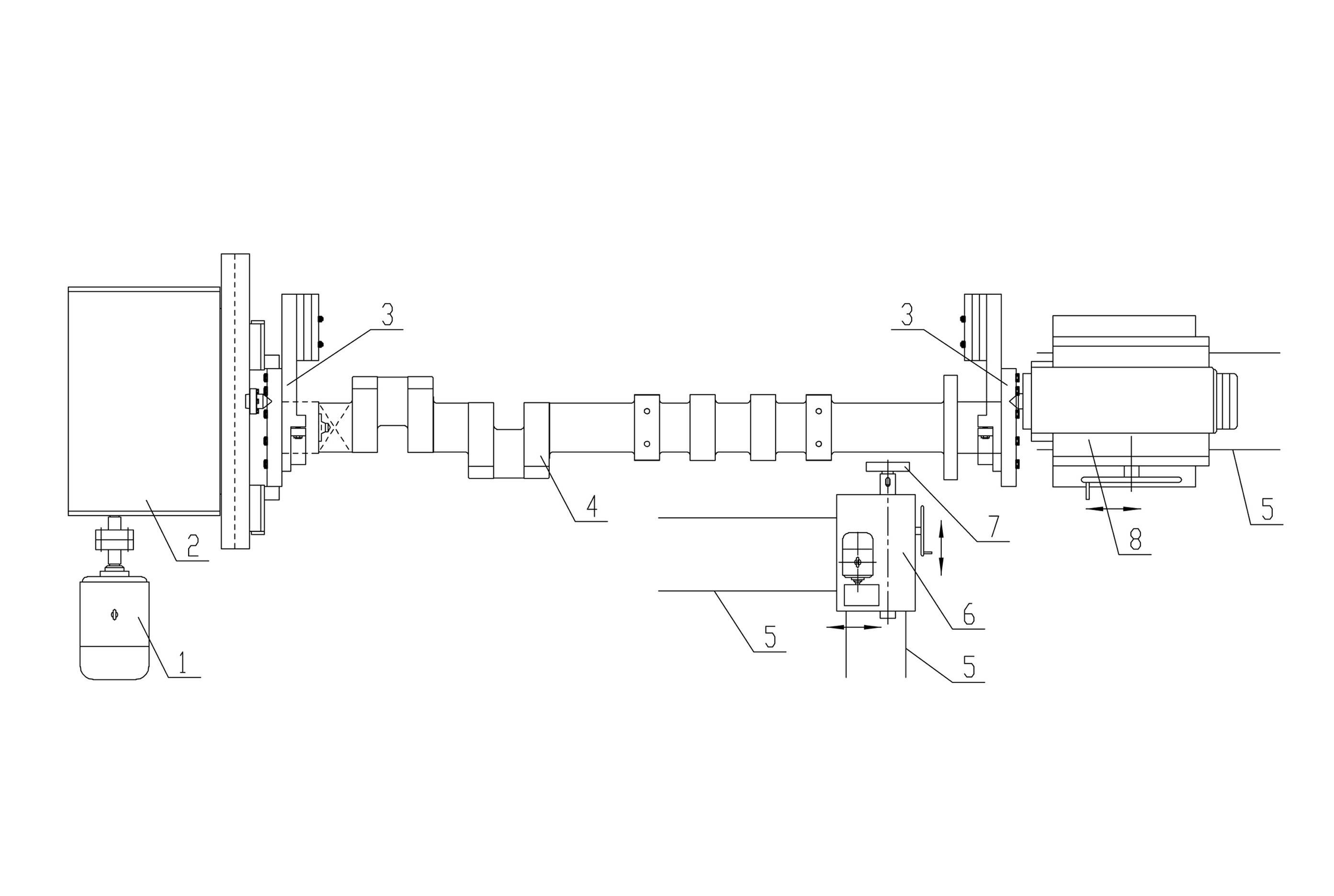

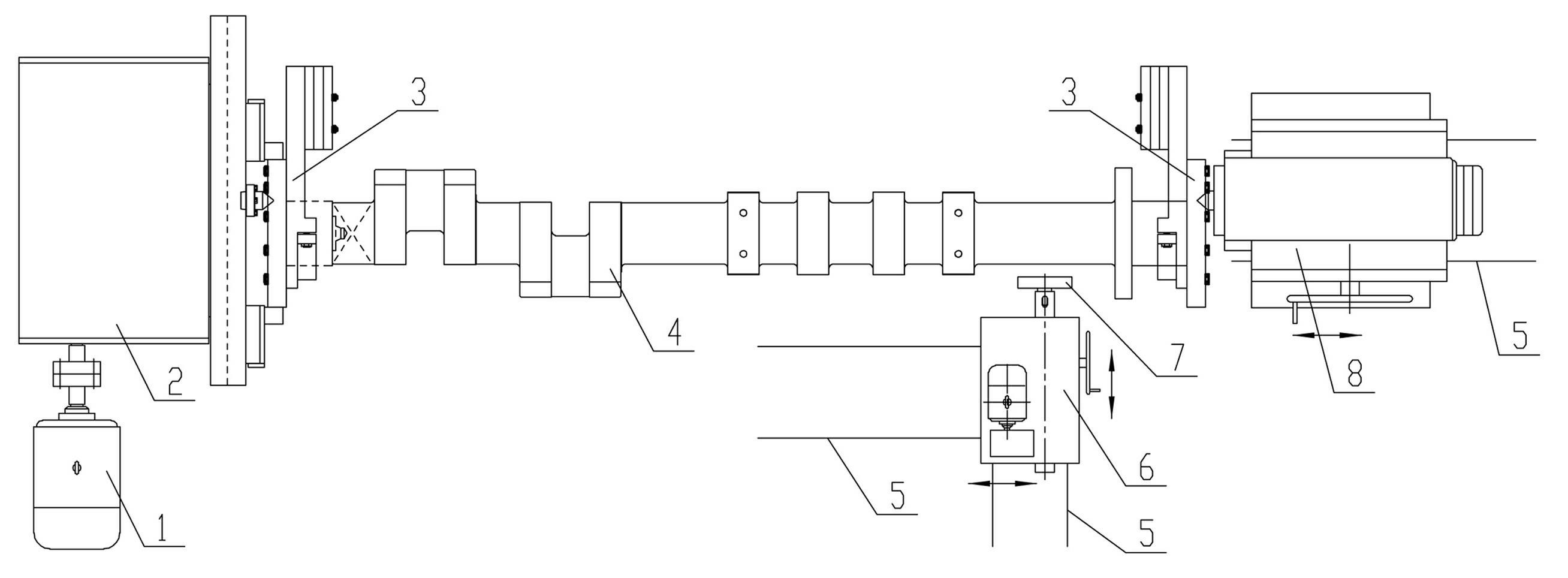

[0026] Such as Figure 1-2 As shown: the technical solution is to add a counterweight mechanism, change the traditional turning to milling, and break away from the support of the center frame and the processing of large-tonnage rough turning machine tools, forming a new processing technology. The process equipment is mainly composed of a DC motor 1, a rotating mechanism 2, a counterweight mechanism 3, a workpiece 4, a slideway 5, a boring and milling power head 6, a milling cutter disc 7, and a clamping mechanism 8.

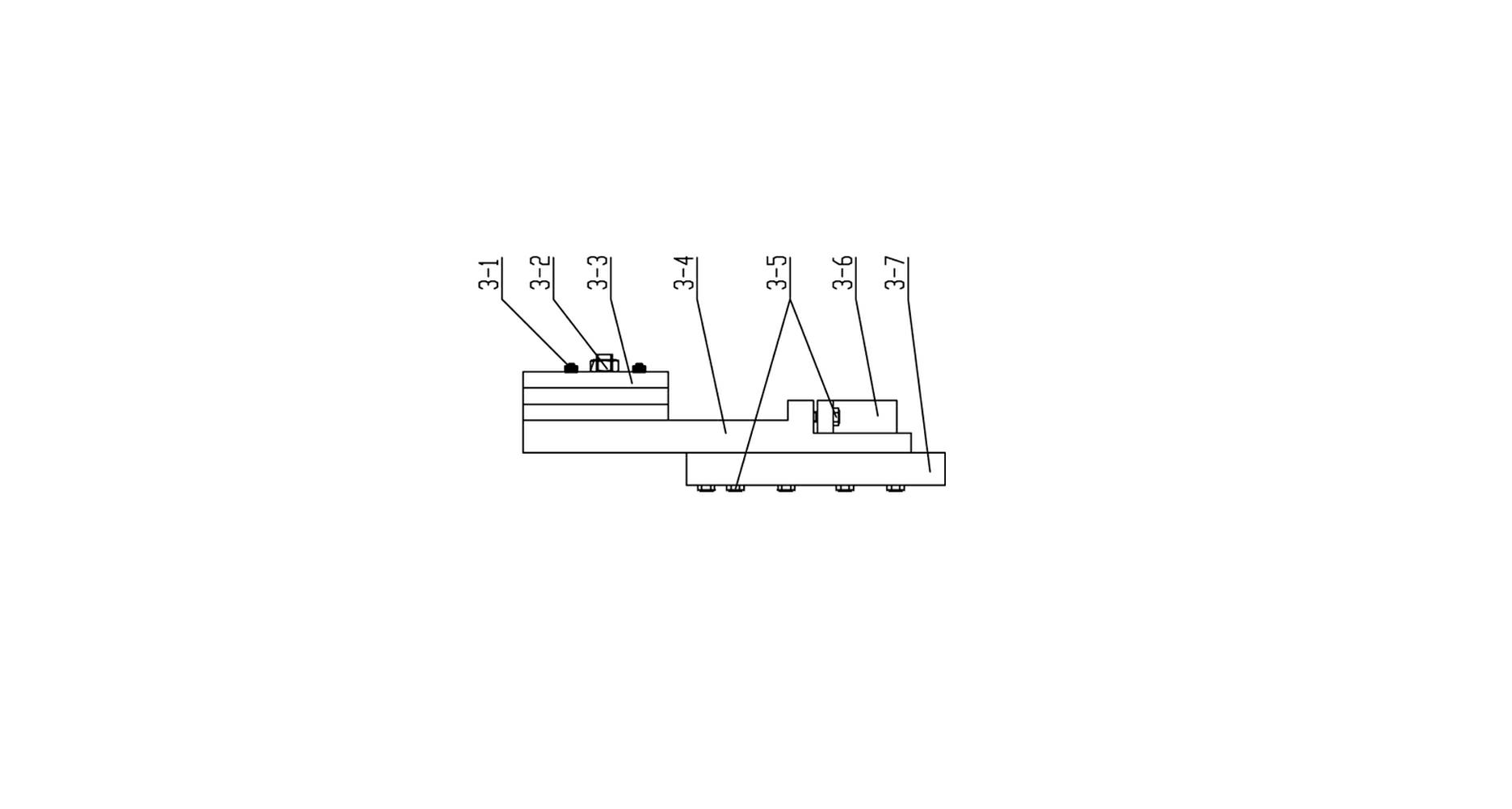

[0027] The counterweight mechanism consists of stud bolts 3-1, T-shaped bolts 3-2, counterweight blocks 3-3, counterweight carcass 3-4, closing bolts 3-5, gland 3-6, top plate 3- 7 composition. The stud bolt 3-1 and the T-bolt 3-2 fix the counterweight 3-3 on the counterweight carcass 3-4, and the gland 3-6 and the counterweight carcass 3-4 are tightened to secure the workpiece 4. The shaft ends are clamped, and the counterweight carcass 3-4 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com