Grinding method for ensuring template planeness of high-precision die

A flatness and high-precision technology, applied in the field of grinding, can solve problems such as deformation and inability to meet high-precision molds, and achieve the effects of ensuring special requirements, reducing scrap rate, and reducing positional errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

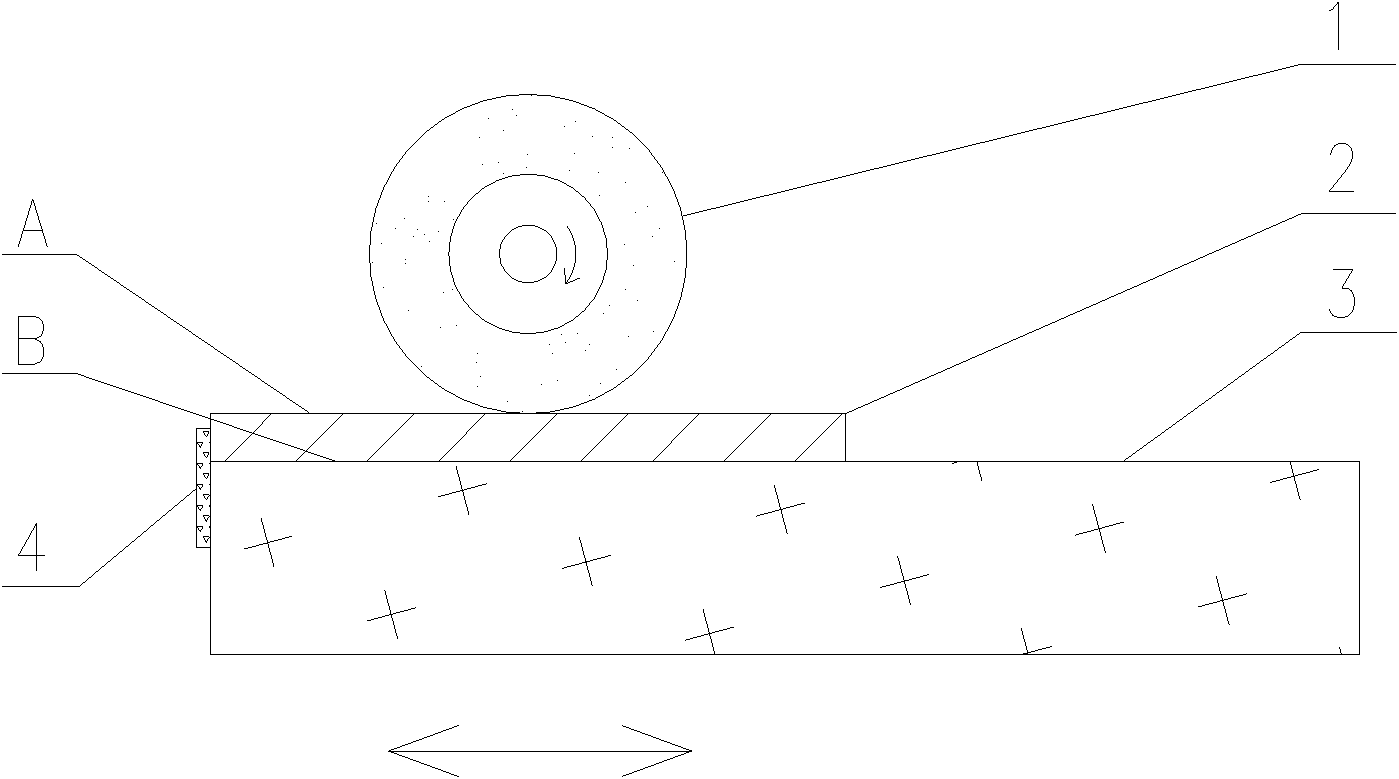

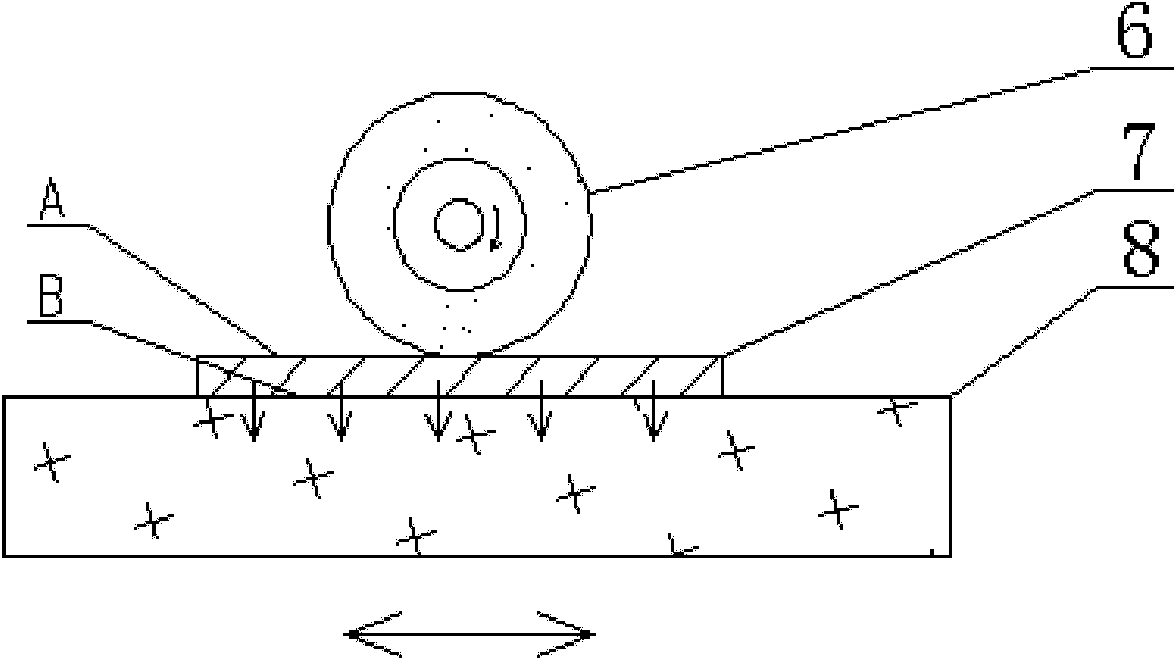

[0022] A grinding method to ensure the flatness of high-precision mold templates. The grinding process of the template plane: (1) Put the template 2 on the electromagnetic chuck 3 of the grinder, rotate the magnetic button to make the electromagnetic disk in a magnetized state, and adjust the grinding wheel , rough grinding one side; (2) Install a baffle on one side of the electromagnetic chuck 3, and the template 2 is close to the baffle 4, and coarsely grind the other side; (3) Rotate the magnetic button to make the electromagnetic disk 3 in a demagnetized state, and finish dressing the grinding wheel 1 , the template 2 uses the residual magnetism and the baffle plate 4 to repeatedly finely grind both sides, so that the flatness of the template 2 reaches the requirement within 0.01mm.

[0023] Concrete structure and working process thereof of the present embodiment:

[0024] The grinding method of the high-precision mold template of the present invention, the grinding machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com