Process for removing arsenic from diethylene triamine penta(methylene phosphonic acid) (DTPMPA)

A technology of diethylenetriaminepentamethylenephosphonic acid and process, which is applied in the field of arsenic removal process of diethylenetriaminepentamethylenephosphonic acid, and can solve the problems of increasing production cost, large consumption of ammonium thioacetate and difficulty in purchasing and other issues to achieve the effect of low cost and low price

Inactive Publication Date: 2011-06-15

SHANDONG TAIHE WATER TREATMENT TECH CO LTD

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the prior art, there is no process for dearsenic treatment of aminotrimethylene phosphonic acid, only a patent No. 200810230638.9 discloses a hydroxyethylene diphosphonic acid with an arsenic content ≤ 3ppm and its preparation process , the process uses ammonium thioacetate as the arsenic removal reagent in the production process of hydroxyethylidene diphosphonic acid, but ammonium thioacetate is expensive and difficult to purchase, and there are few domestic manufacturers, basically relying on imports, and the method uses The amount of ammonium thioacetate is too large, which greatly increases the production cost, which is not conducive to the practical application in industrialized production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

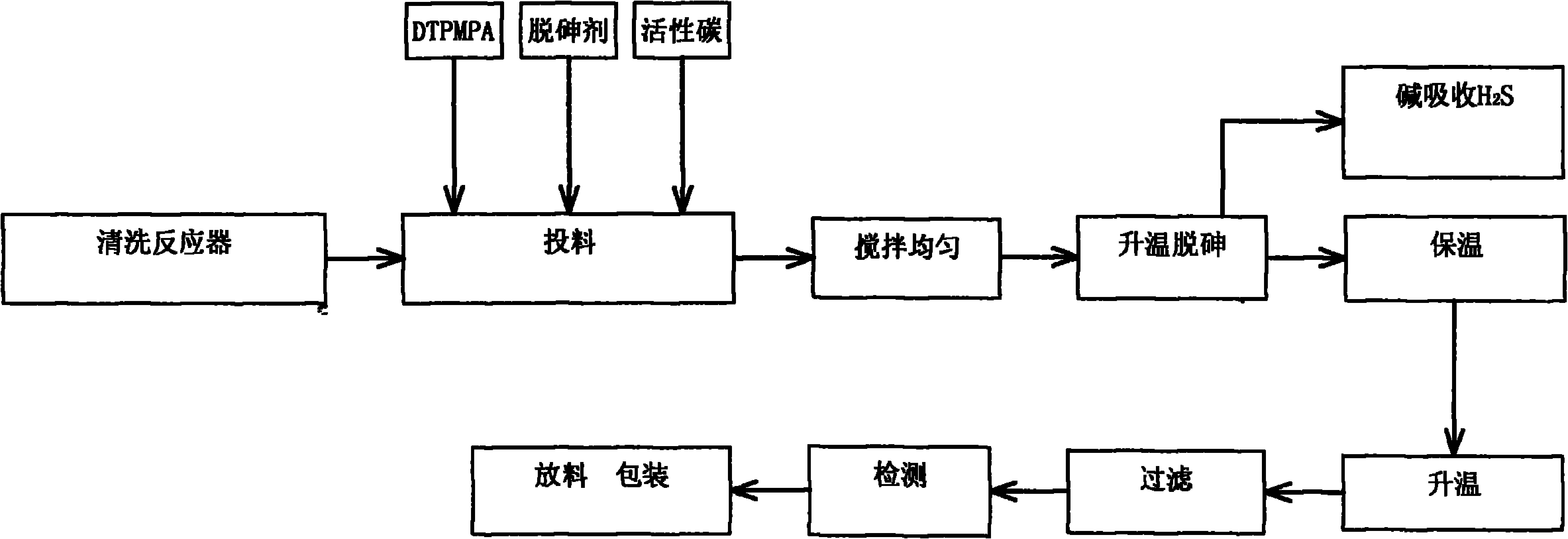

Login to View More Abstract

The invention provides a process for removing arsenic from diethylene triamine penta(methylene phosphonic acid) (DTPMPA). The process has the advantage of low production cost and comprises the following steps: adding 400-1000 parts by weight of DTPMPA which does not undergo arsenic removal treatment to a reaction kettle, pumping steam from the jacket of the reaction kettle to adjust the temperature of the materials in the kettle to 20-70 DEG C, then adding 0.1-1 part by weight of arsenic removing agent phosphorus pentasulfide, then adding 0.2-2 parts by weight of active carbon, washing the charging hole with 0.5-2 parts by weight of pure water after charging and then preserving the heat in the temperature range of 20-70 DEG C for 1-5 hours; and later filtering the DTPMPA, heating the clean DTPMPA after filtration to 80 DEG C, externally steaming the clean DTPMPA under negative pressure for 1-3 hours, before completing external steaming, firstly analyzing the activity, adding pure water for dilution according to the activity result, pumping cooling water from the jacket of the reaction kettle to cool the materials in the kettle to 40-50 DEG C and discharging the DTPMPA.

Description

A process for removing arsenic from diethylenetriaminepentamethylenephosphonic acid technical field The invention relates to a process for removing arsenic, in particular to a process for removing arsenic of diethylenetriaminepentamethylene phosphonic acid. Background technique Diethylenetriaminepentamethylenephosphonic acid, also known as diethylenetriaminepentamethylenephosphonic acid, has a molecular formula of C9H28015N3P5, and its English abbreviation is DTPMPA. It is an organic phosphonic acid scale and corrosion inhibitor. , zinc and other metal ions form stable complexes, dissolve oxides on the metal surface, and can still play a good role in corrosion and scale inhibition at 250 ° C, and is still very stable at high pH, not easy to hydrolyze, and generally light It is not easy to decompose under hot conditions, and its acid and alkali resistance and chlorine oxidation resistance are better than other organic phosphonic acids (salts). It can form a six-membered ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07F9/38

Inventor 程终发王忠英齐晓靓孙宝季王东海王燕平

Owner SHANDONG TAIHE WATER TREATMENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com