Preparation method of polyester polyol of modified isocyanate, preparation method of isocyanate prepolymer and preparation method of polyurethane elastomer

A technology of isocyanate prepolymerization and polyester polyol, which is applied in the field of isocyanate modified polyester polyol preparation, isocyanate prepolymer preparation and polyurethane elastomer preparation, which can solve the problems of increased material cost, inconvenient processing, high melting point, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

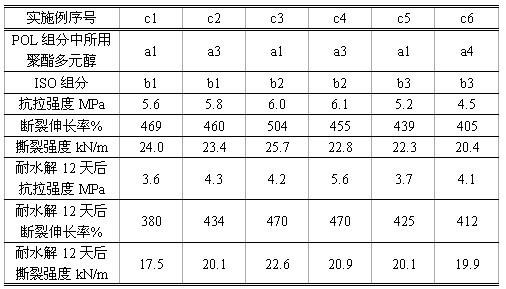

Examples

Embodiment 1

[0013] Commercially available dry polyethylene adipate / diethylene glycol a1 has a hydroxyl value of 75 mgKOH / g, and the molar ratio of ethylene glycol to diethylene glycol is 1:1 for comparison.

Embodiment 2

[0015] Commercially available dry polyethylene adipate / diethylene glycol a2 has a hydroxyl value of 200 mgKOH / g, and the mass ratio of ethylene glycol to diethylene glycol is 1:1 for comparison.

[0016] Embodiment 1 of the present invention

[0017] Weigh polyester polyol a1 and carbodiimide-modified MDI in a molar ratio of 2.1:1, place in a reaction kettle, react at 60-80°C for 2-3 hours under the protection of nitrogen, and discharge to obtain Isocyanate-modified polyester polyol a3. Among them, the carbodiimide-modified MDI is provided by Dow Chemical Company, the brand is Isonate 143L, 2~2.2 functionalities, and the NCO mass fraction is 28%~30%, which is used to improve the hydrolysis resistance and storage stability of MDI .

[0018] Embodiment 2 of the present invention

[0019] Weigh polyester polyol a2 and carbodiimide-modified MDI at a molar ratio of 2.2:1, place in a reaction kettle, react at 60-80°C for 2-3 hours under the protection of nitrogen, and discharge t...

Embodiment 3

[0035]Prepare the POL components and weigh them respectively: polyester polyol is a3 100 kg, chain extender ethylene glycol 8 kg, catalyst Dabco EG 1.6 kg (U.S., produced by Air Products, commercially available), foam stabilizer DC193 (U.S. , produced by Air Products, commercially available) 0.25 kg and foaming agent water 0.45 kg. Put the weighed raw materials in a reaction kettle at 20-50°C, mix them well for 2-4 hours, discharge them, and keep them sealed. The temperature of the POL component and the ISO (prepolymer b2) component was adjusted so that the temperature of the POL component was 38-40°C, and the temperature of the ISO component was 41-43°C. Using a low-pressure foaming machine, according to the ratio of isocyanate index to 100%, quickly mix the POL component and ISO component in the mixing chamber at a speed of 6000 rpm, and pour it into a mold with a mold temperature of 45°C. Molding, keeping the pressure for 5 minutes, demoulding, and then curing at 75°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com