High-temperature-stable La(Fe,Si)13-based multi-interstitial-atom hydride magnetic refrigeration material with large magnetic entropy change and preparation method thereof

A magnetic refrigeration material, high-temperature stable technology, applied in the direction of magnetic materials, metal hydrides, heat exchange materials, etc., can solve the problems of difficulty in ensuring the uniformity of interstitial hydrides, complex process flow, and reduced material performance. Rich, simple preparation process, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

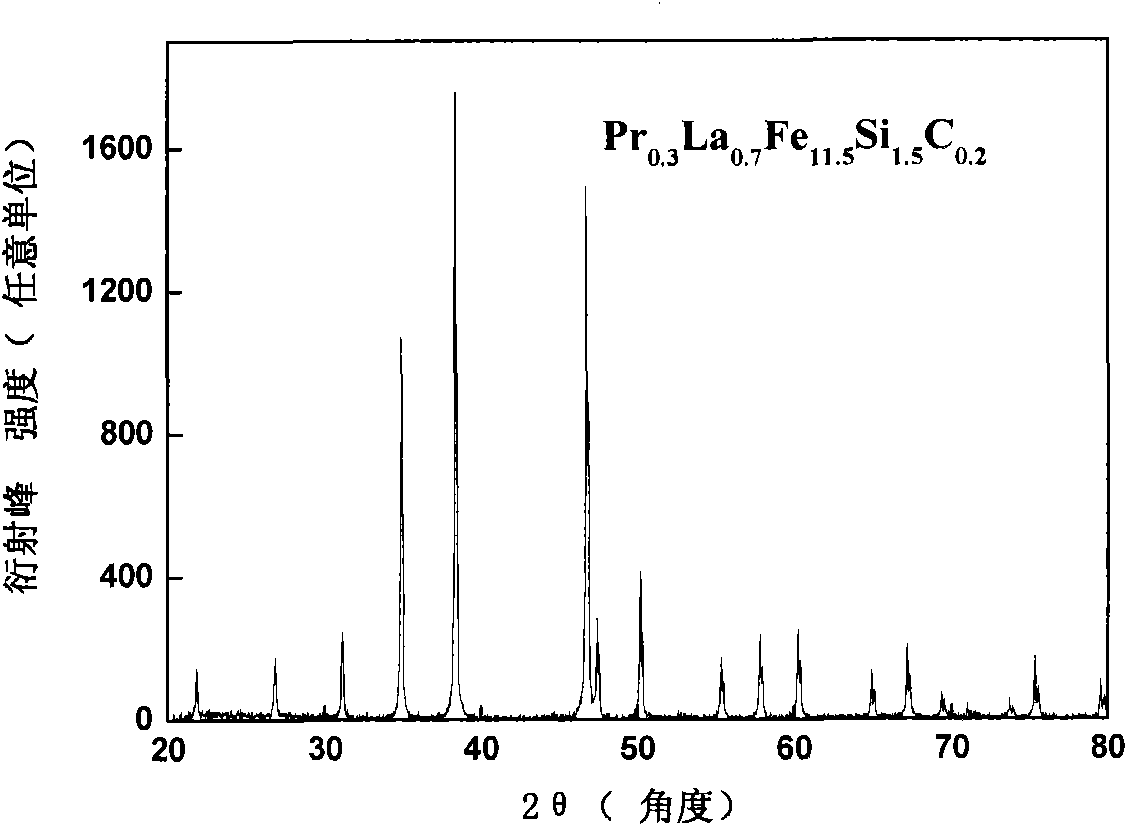

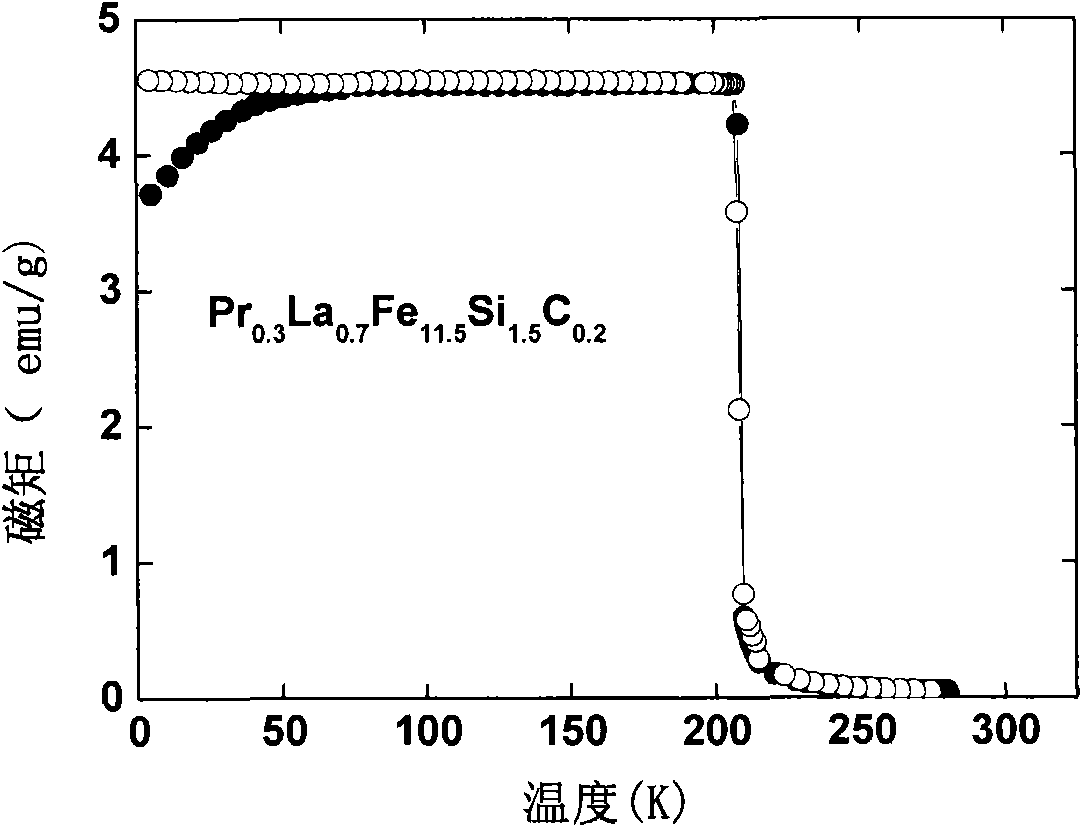

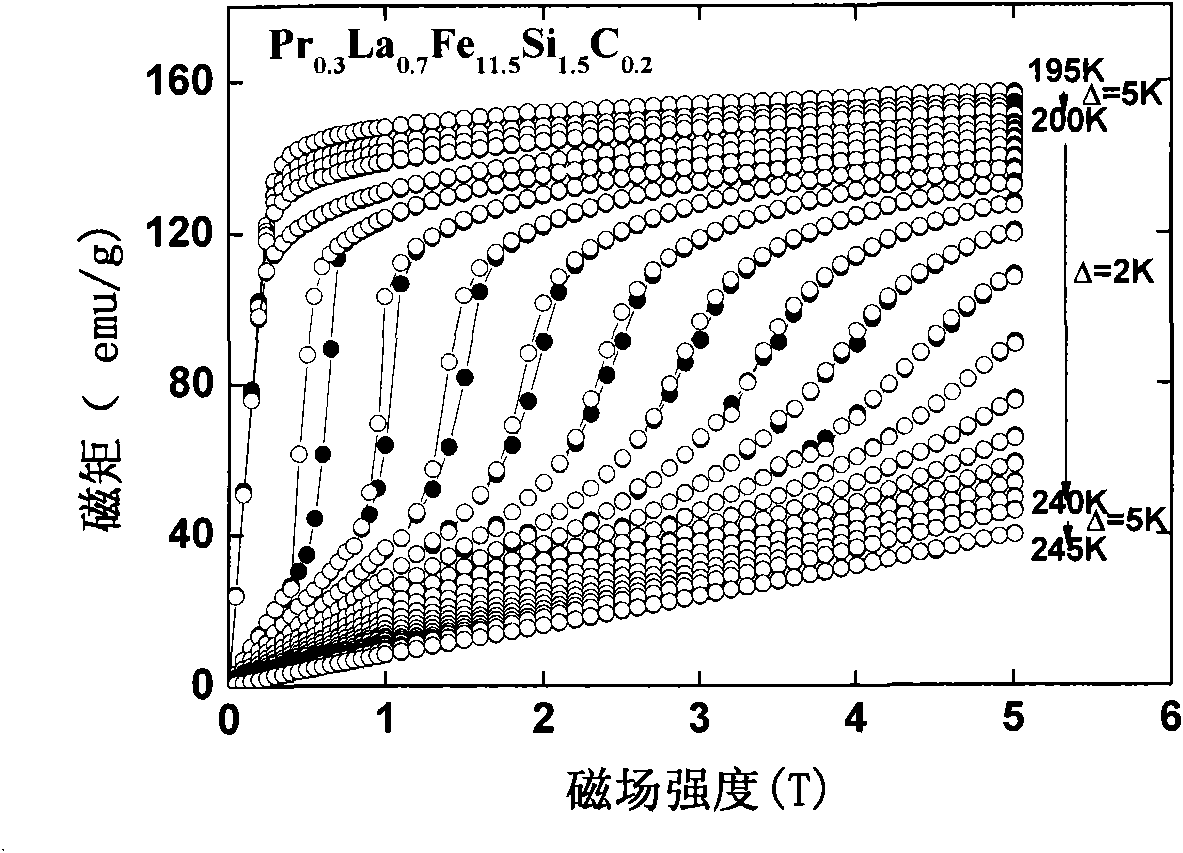

[0084] Embodiment 1 prepares Pr 0.3 La 0.7 Fe 11.5 Si 1.5 C 0.2 Interstitial master alloy

[0085] The preparation formula is Pr 0.3 La 0.7 Fe 11.5 Si 1.5 C 0.2 The gap master alloy, the specific process is:

[0086] i) According to the chemical formula Pr 0.3 La 0.7 Fe 11.5 Si 1.5 C 0.2 Weighing materials, commercially available rare earth metal La, Pr (manufacturer name: Hunan Shenghua Rare Earth Metal Material Co., Ltd.) and Fe, Fe-C master alloy (carbon content is 4.03% by weight), and Si with purity higher than 99.9% by weight Raw materials are mixed; wherein, the rare earth metals La and R are excessively added by 5% (atomic percentage) to compensate for volatilization and burning loss during the smelting process;

[0087] ii) Put the raw materials prepared in step i) into the electric arc furnace, and evacuate to 2×10 -5 Above Pa, after cleaning 1 or 2 times with the usual high-purity argon gas cleaning method, use the usual method t...

Embodiment 2

[0101] Embodiment 2: prepare Pr 0.3 La 0.7 Fe 11.5 Si 1.5 C 0.2 H 0.6 and Pr 0.3 La 0.7 Fe 11.5 Si 1.5 C 0.2 H 1.2

[0102] interstitial master alloy Pr 0.3 La 0.7 Fe 11.5 Si 1.5 C 0.2 Introduce the interstitial H atoms again to prepare the chemical formula Pr 0.3 La 0.7 Fe 11.5 Si 1.5 C 0.2 h 1.2 and Pr 0.3 La 0.7 Fe 11.5 Si 1.5 C 0.2 h 1.2 The compound, the specific process is:

[0103] The fresh Pr prepared by embodiment 1 0.3 La 0.7 Fe 11.5 Si 1.5 C 0.2 The interstitial master alloy is broken into particles, placed in a high-pressure container, and vacuumed to 2×10 -5 Above Pa, at 350°C, pass high-purity H into the high-pressure vessel 2 , the gas pressure is 1.0 and 1.5 atmospheres respectively, and the inhalation time is kept for 5 hours and 2 hours; then put the high-pressure container into water at room temperature (20°C), and at the same time, use a mechanical pump to remove the remaining hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com