Device for automatically extracting biological component on the basis of electromagnetic propulsion grinding and centrifugal separation

An electromagnetic drive and centrifugal separation technology, applied in biochemical equipment and methods, biochemical instruments, biomass post-processing, etc., can solve the problems of difficult implementation and high cost, and achieve the advantages of convenient operation, less moving parts, and improved work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention proposes an automatic extraction device for biological components based on electromagnetically driven grinding and centrifugal separation. The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

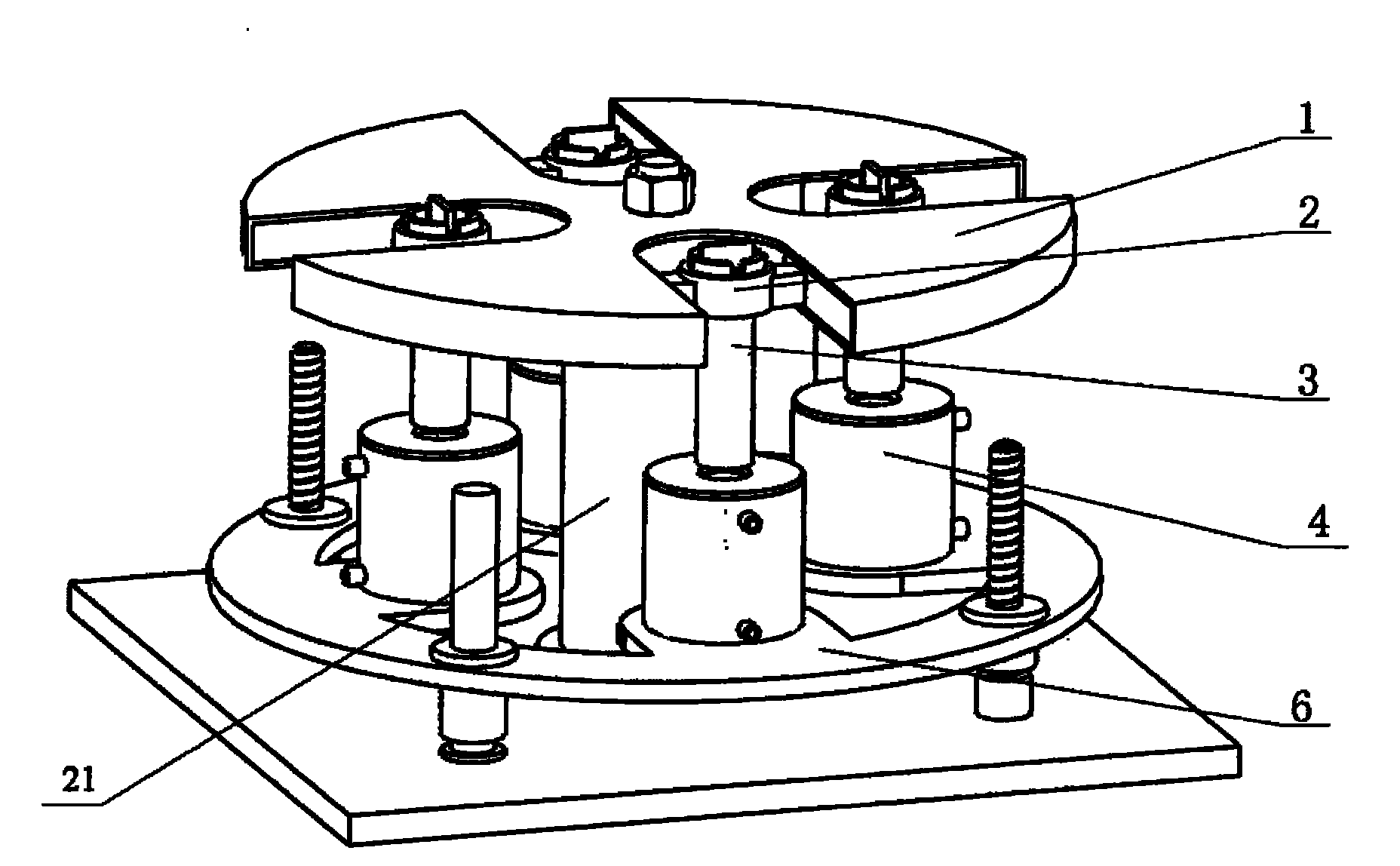

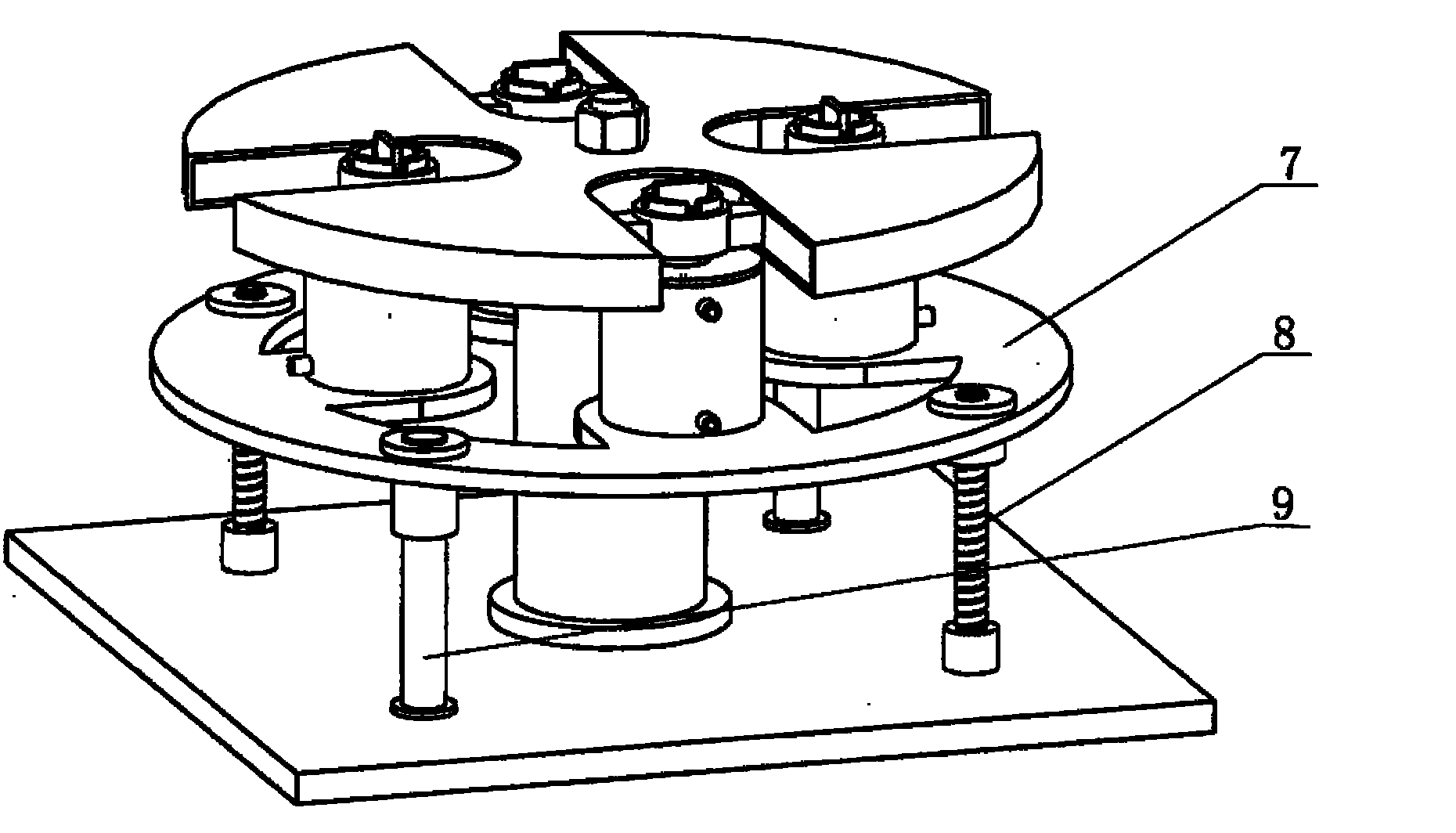

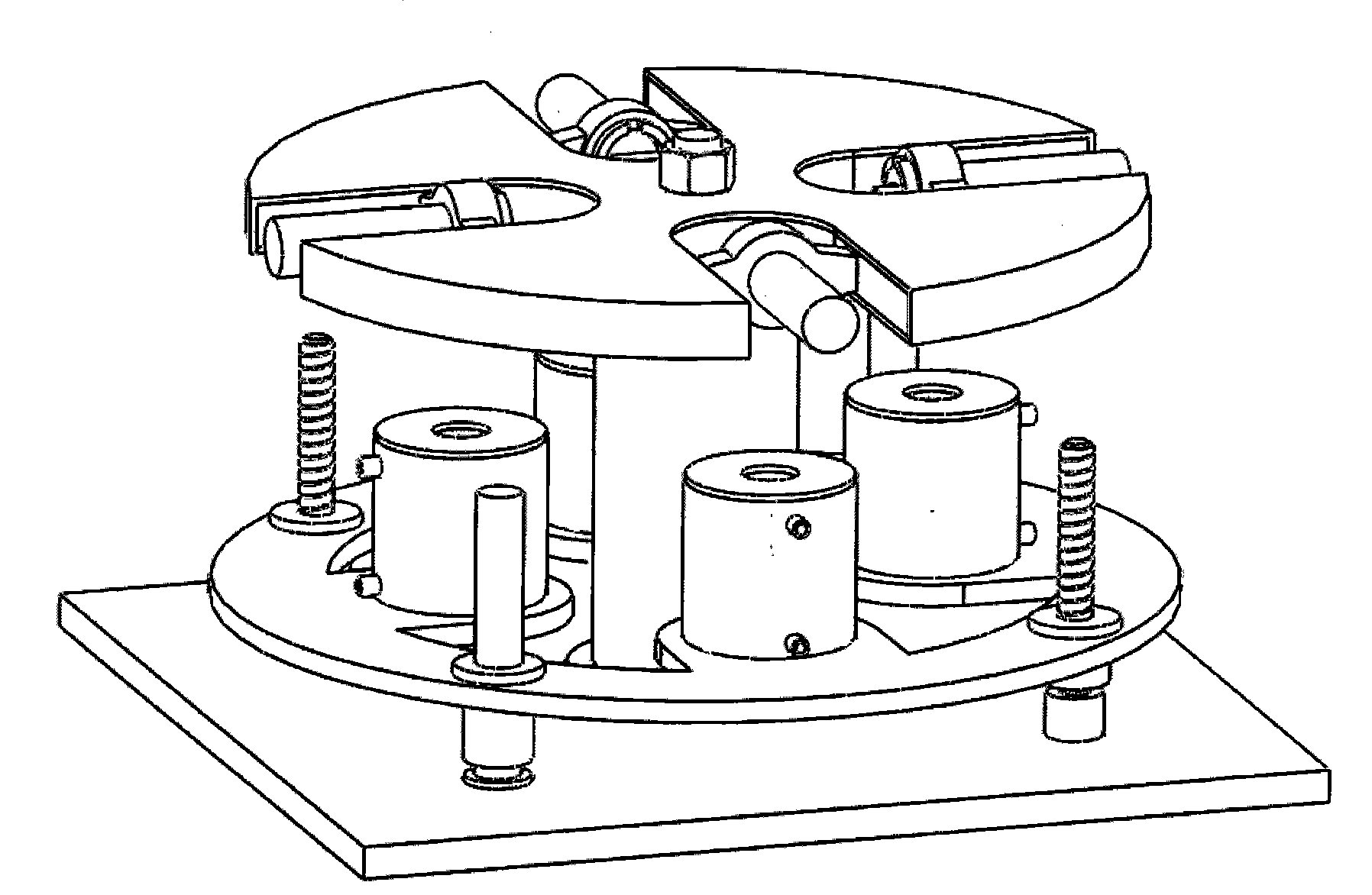

[0026] Such as Figure 1-Figure 5 As shown, the structure of the device includes: a lifting mechanism 6, an electromagnetic drive module 5 installed on the lifting mechanism 6, a central shaft 21, a centrifugal rotor body 1 installed on the top of the central shaft 21, and a centrifugal rotor body suspended on the centrifugal rotor body 1. Hanger 2, and the operation bottle 3 installed on the centrifugal hanger 2.

[0027] The centrifugal rotor body 1 adopts a horizontal rotor structure, and four centrifugal hangers 2 are evenly arranged around the axis on the centrifugal rotor body 1 . The main structure of the centrifugal rotor body 1 is an axisymmetric disc, and a corresponding groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com