Method for increasing endpoint carbon content of converter

A converter end-point and carbon content technology, which is applied in the end-point control of converter steelmaking to increase the carbon content of the converter end-point, can solve the problem of not being able to effectively control the end-point carbon content and the content of other components, eliminating high costs, and greatly affecting quality and other problems, to achieve the effect of compact production organization mode, effective heat, and reduced reblowing times

Inactive Publication Date: 2011-06-15

PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

View PDF2 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the content of [O] in molten steel obtained by high-strength supplementary blowing method is relatively high, which has a great impact on the quality of molten steel, and the elimination cost is also high

Therefore, the current end-point control methods for converter steelmaking cannot effectively control the carbon content and the content of other components at the end point, so it is urgent to improve the existing converter end point [C] control method to improve the end point of the converter. [C] content

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

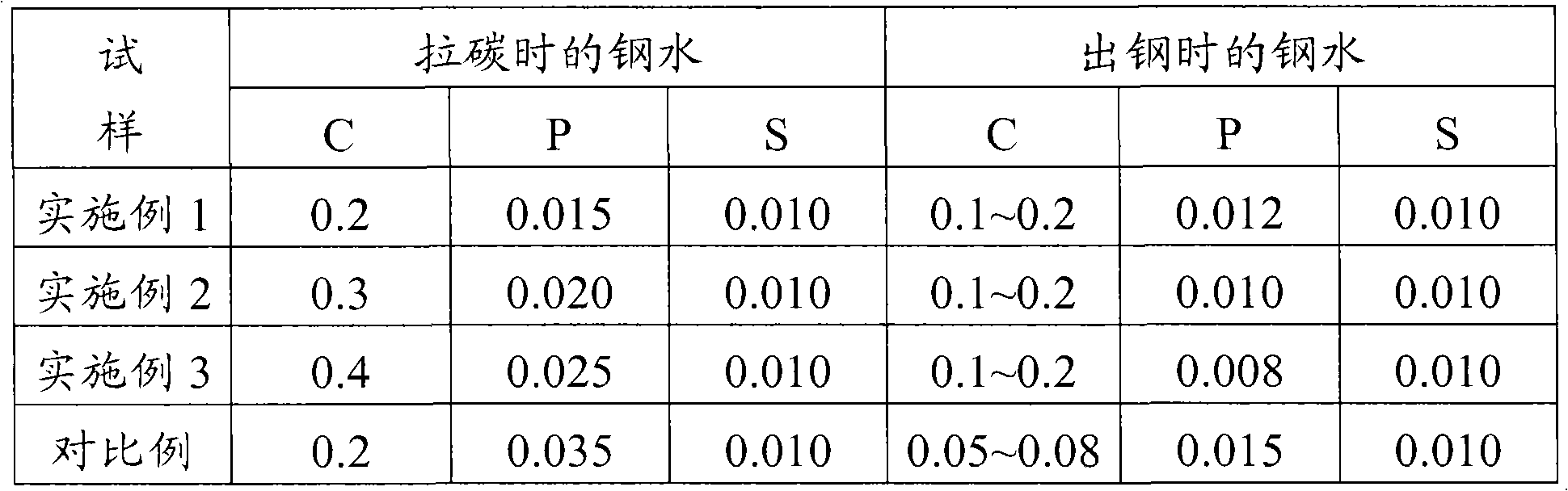

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for increasing the endpoint carbon content of the converter. The method comprises the following steps: adding steel scraps in the molten iron of a converter, then adding slag while controlling the initial basicity of slag to 2.5-3 and controlling the heating speed of the process; supplying oxygen, converting to control the phosphorus content of molten iron to lessthan 0.025%; and performing catch carbon while controlling the catch carbon temperature to 1620-1660 DEG C, controlling the carbon content of molten iron to 0.2%-0.4% and controlling the adding time of all the auxiliary materials to be less than 3min, wherein when a dephosphorization oxygen lance is used to supply oxygen, and the dephosphorization oxygen lance is 1.2m-1.6m above the liquid level of a molten bath in the converter during the preset time before catch carbon. The method of the invention adopts an compact production organization model, thus the number of reblowings can be reduced and the heat of the converter can be effectively utilized.

Description

The method of increasing the carbon content at the end point of converter technical field The invention relates to the field of steelmaking, in particular to the end point control of converter steelmaking, that is, a method for increasing the carbon content at the end point of the converter. Background technique Steelmaking end point control is an important operation at the end of converter blowing, because phosphorus and sulfur are always removed to the range required by the end point as far as possible in advance during the blowing process. Compared with molten steel temperature control, converter end point carbon control is particularly important. Important and difficult, it will affect the operation of the entire converter smelting process, so the main content of the converter's end point control is end point carbon control and molten steel temperature control. At present, oxygen converters often use "high carbon" operation to smelt high carbon steel. The so-called "...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C21C5/30

Inventor 聂绍刚陈靓李盛黄登华雷辉曾耀先

Owner PANGANG GROUP VANADIUM TITANIUM & RESOURCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com