Wind machine blade airfoil profile capable of controlling flow stalling through standing vortex

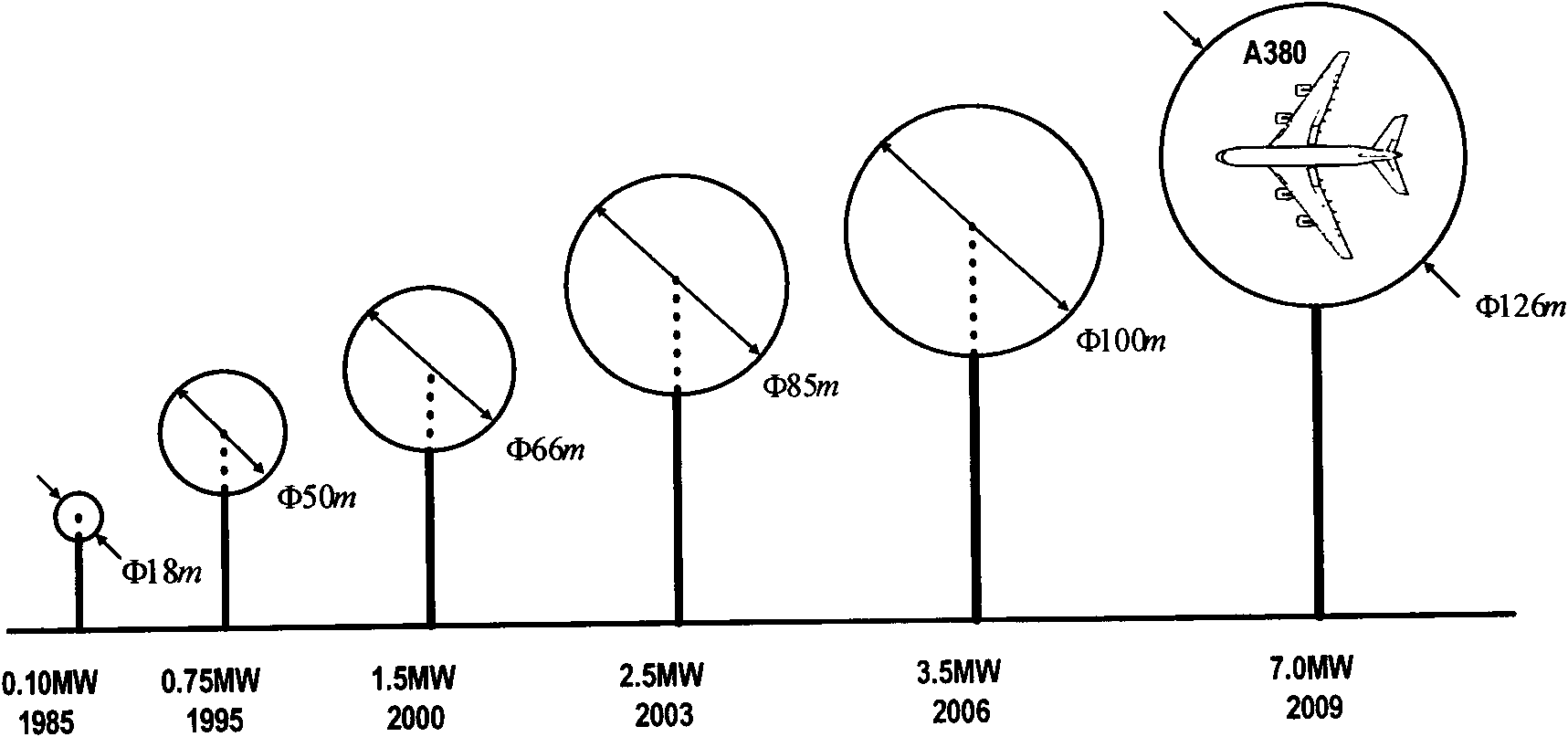

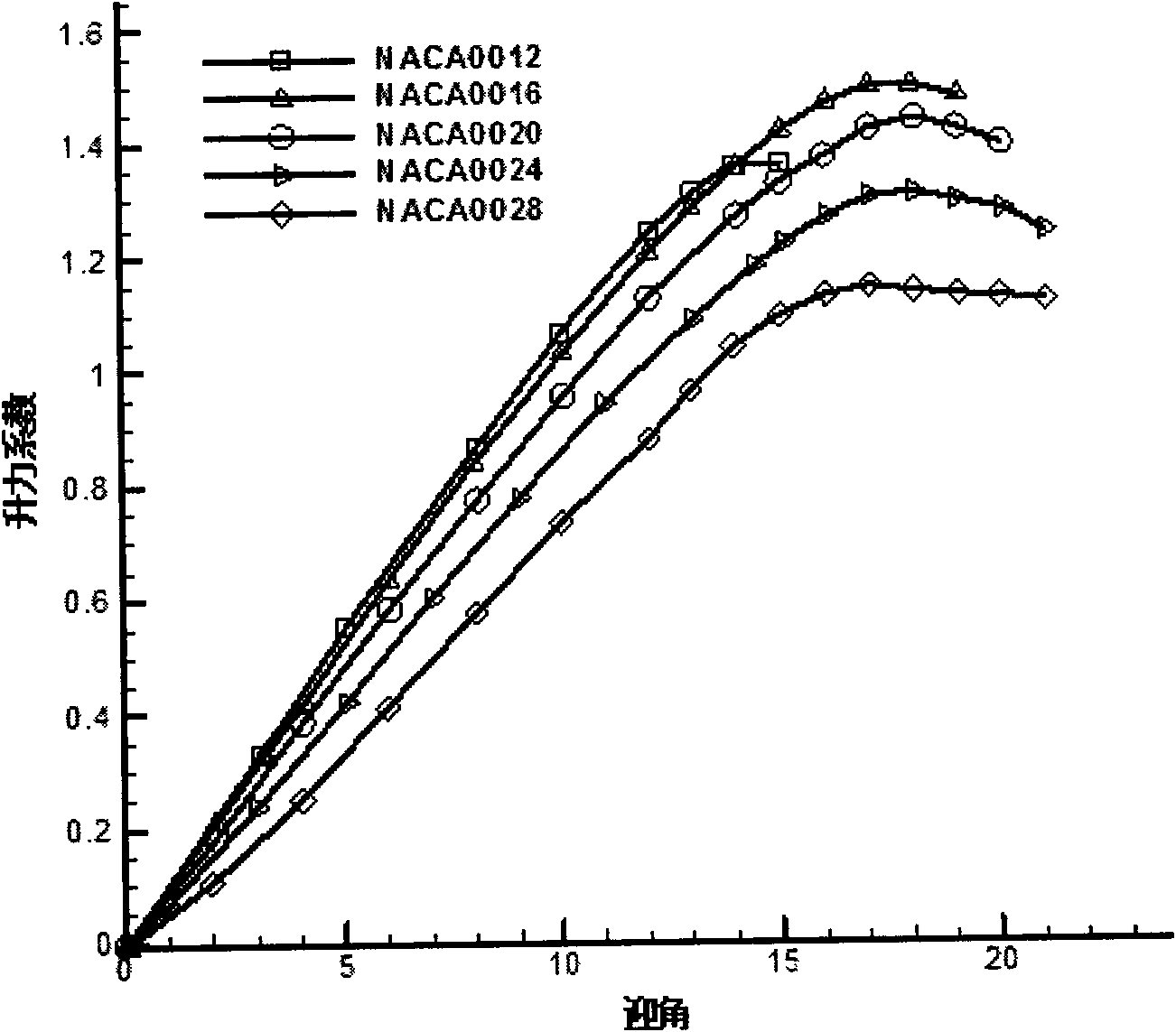

A wind turbine blade, flow control technology, applied to the airfoil of the wind turbine blade. In this field, it can solve the problems of high angle of attack, high lift and flow stall, and achieve the effect of expanding the working range of angle of attack, reducing the risk of structural damage, and reducing unsteady loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In this implementation, the purpose of this embodiment is realized by modifying the upper surface of the basic airfoil and installing Gurney flaps at the trailing edge point of the basic airfoil.

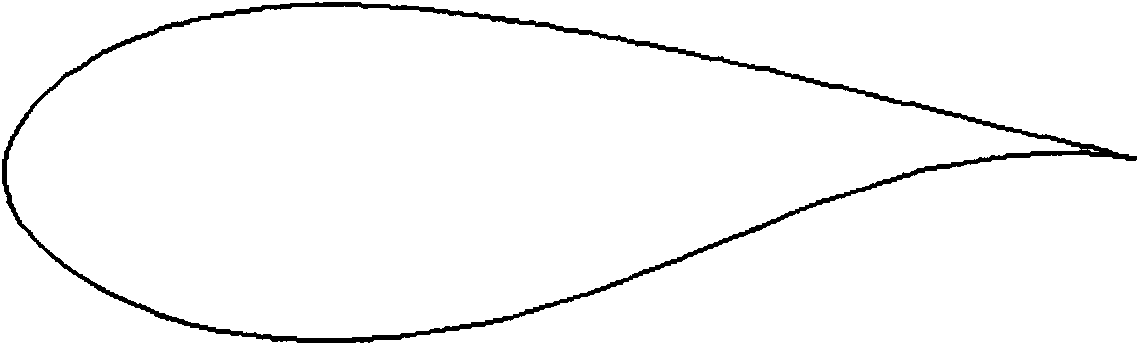

[0025] as attached image 3 As shown, this embodiment selects the FFA-W3-301 fan airfoil as the basic airfoil. The chord length of the basic airfoil is 983.5mm.

[0026] as attached Figure 4 As shown, on the upper airfoil of the basic airfoil, the airfoil between the modification starting point 1 and the airfoil trailing edge point 6 is modified. Place the upper surface of the base airfoil in the xoy plane and make the chord of the airfoil coincide with the x-axis.

[0027] The leading edge point of the airfoil is located at the coordinate origin O, and the trailing edge point of the airfoil is located on the positive semi-axis of the x-axis.

[0028] When trimming, the position of 30% chord length from the upper airfoil to the leading edge point of the airfoil is taken ...

Embodiment 2

[0038] This implementation is to make a fan airfoil for wind power generation.

[0039] In this implementation, the purpose of this embodiment is realized by modifying the upper surface of the basic airfoil and installing Gurney flaps at the trailing edge point of the basic airfoil.

[0040] as attached image 3 As shown, this embodiment selects the FFA-W3-301 fan airfoil as the basic airfoil. The chord length of the basic airfoil is 983.5mm.

[0041] as attached Figure 5 As shown, on the upper airfoil of the basic airfoil, the airfoil between the modification starting point 1 and the airfoil trailing edge point 6 is modified. The upper surface of the basic airfoil is placed in the xoy plane, so that the leading edge point of the airfoil is located at the coordinate origin O, and the trailing edge point of the airfoil is located on the positive semi-axis of the x-axis.

[0042] When trimming, take the position of 35% chord length from the upper airfoil of the airfoil to the...

Embodiment 3

[0052] This implementation is to make a fan airfoil for wind power generation.

[0053] In this implementation, the purpose of this embodiment is realized by modifying the upper surface of the basic airfoil and installing Gurney flaps at the trailing edge point of the basic airfoil.

[0054] as attached image 3 As shown, in this embodiment, the NACA-63-430-V fan airfoil is selected as the basic airfoil. The chord length of the basic airfoil is 1000mm.

[0055] as attached Figure 5 As shown, on the upper airfoil of the basic airfoil, the airfoil between the modification starting point 1 and the airfoil trailing edge point 6 is modified. The upper surface of the basic airfoil is placed in the xoy plane, so that the leading edge point of the airfoil is located at the coordinate origin O, and the trailing edge point of the airfoil is located on the positive semi-axis of the x-axis.

[0056] When trimming, the position of 40% of the chord length from the upper airfoil to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Chord length | aaaaa | aaaaa |

| Chord length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com