Heat exchange equipment applying multi-layer heat exchange tubes

A technology of heat exchange equipment and heat exchange tubes, which is applied in heat exchange equipment, lighting and heating equipment, tubular elements, etc., can solve the problems of large loss of raw materials, local corrosion of enhanced heat exchange tubes, and limitation of processing technology, and achieve the design life And the effect of long service life, improving heat exchange efficiency and reducing manufacturing cost

Inactive Publication Date: 2011-06-15

SHANGHAI KEMI STEEL TUBE

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

1. Due to the specifications of cold processing equipment, the finished heat exchange tubes are greatly limited in terms of specifications and length;

2. Due to the cold processing steps, the loss of raw materials is relatively large;

3. Due to the complex cold processing process, the processing accuracy of the product is uneven;

4. It is difficult to guarantee the quality of the finished product by the inspection method and inspection method of the cold processing process;

5. Limited by the processing technology, the tube making efficiency is not high;

6. Most of these four types of heat exchange tubes have special shapes, which bring a lot of inconvenience to the production of heat exchanger equipment such as the disposal of bellows and baffles of outer grooved tubes;

7. These four types of heat exchange tubes have been cold-worked, and there are residual stresses on the tube body, which will form turbulent flow when the medium passes through, which strengthens the local corrosion of the heat exchange tubes, so it has a certain impact on the service life of the heat exchanger equipment. negative impact

Due to the above reasons, the heat exchange equipment in the prior art has entered a technical bottleneck, and it is difficult to greatly increase the heat exchange area and heat exchange efficiency, which restricts the development of heat exchange equipment and is difficult to meet the needs of the market

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

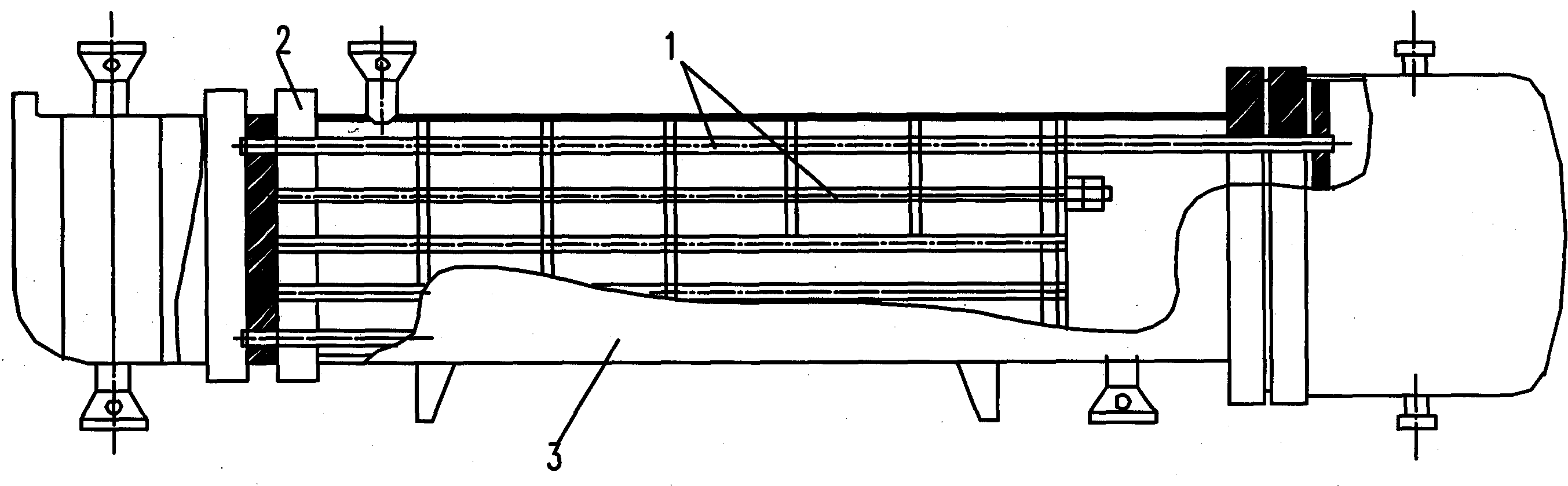

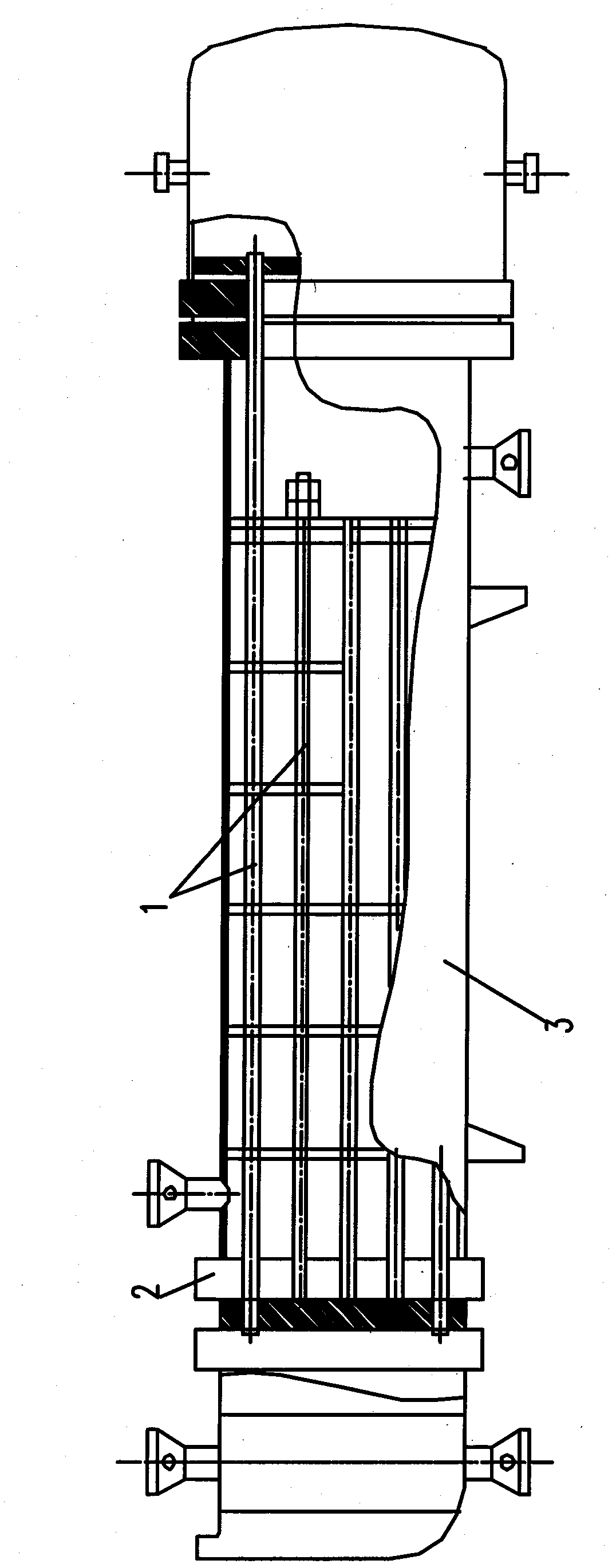

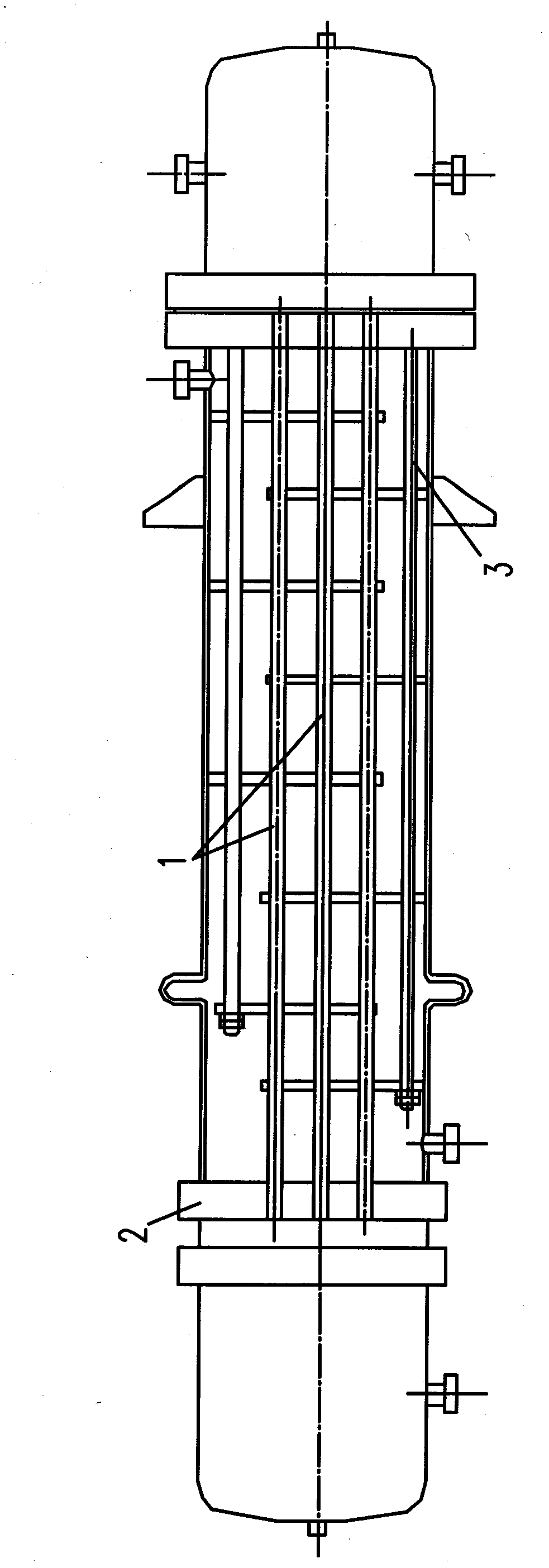

The invention discloses heat exchange equipment applying multi-layer heat exchange tubes. The heat exchange equipment at least comprises a tube bundle body, wherein a tube plate is arranged on the tube bundle body, and a plurality of multi-layer heat exchange tubes are penetrated in the tube plate; each multi-layer heat exchange tube at least comprises an outer tube, and the outer tube is internally provided with a medium channel; the medium channel is internally provided with a heat exchange part which divides the heat exchange channel into a direct heat exchange area exchanging heat with the outer tube and an indirect heat exchange area exchanging heat with the heat exchange part; and the heat exchange medium in the indirect heat exchange area exchanges heat energy with the heat exchange medium of the direct heat exchange area through the heat exchange part. In the invention, because the multi-layer heat exchange tubes are adopted, the heat exchange efficiency of the indirect heat exchange is greatly increased. The heat exchange equipment also has the advantages of low cost, convenience for manufacturing, and the like and is suitable for various industries such as petroleum, chemical engineering, chemical fertilizers, boilers, pharmacy, food, power, nuclear energy, environmental protection, heat supply, and the like.

Description

Heat exchange equipment using multilayer heat exchange tubes technical field The invention relates to the technical field of mechanical equipment, in particular to a heat exchange device for heat exchange. Background technique Heat exchange equipment is an important equipment widely used in many industries, and it is also one of the key equipment for energy saving and consumption reduction. As we all know, the core of the efficiency and energy saving of heat exchange equipment lies in the heat exchange tubes. At present, the most used in the world is the seamless tube of various materials, but its effectiveness has been brought into full play, so the emergence of special-shaped tubes for high-efficiency heat exchangers has greatly improved the efficiency of various heat exchange equipment , its main features are as follows: According to the standard of GB / T24590-2009 "Special Type Tubes for High Efficiency Heat Exchangers", my country's current high-efficiency heat exc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F28F1/00F28F1/10

CPCY02P20/10

Inventor 孔祥锋

Owner SHANGHAI KEMI STEEL TUBE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com