Method for measuring pH value of carbonated concrete pore solution

A concrete and pore solution technology, applied in the direction of material inspection products, etc., can solve the problems that it is difficult to see the pH value of the carbonized concrete pore solution, the pH value of the press filter pore solution, and the difficulty of obtaining the press filter pore solution, etc., achieving low cost , the effect is good, and the effect of solving the difficulty of obtaining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Concrete specimens are made, the size is 3×10×10mm, the cement is 42.5 grade ordinary Portland cement, and the sand is medium sand with a fineness modulus of 2.8. After the specimens were cured for 28 days under standard conditions, in CO 2 The accelerated carbonization test was carried out in an environment with a concentration of 5%, a temperature of 20°C, and a relative humidity of 40%. Concrete mix parameters: the amount of cement is 400kg / m 3 , water-binder ratio 0.5, fine aggregate dosage 650 kg / m 3 .

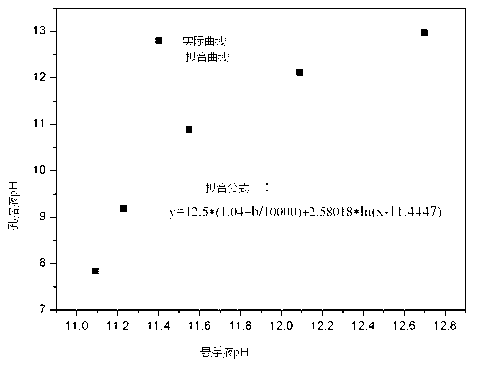

[0019] With the progress of carbonization, there is a fitting curve relationship between the pH value of the pore solution and the pH value of the suspension: , and the correlation coefficient is 0.98. At 3 days of carbonization, the measured pH values of the pore solution and suspension were 12.01 and 12.22 respectively, and the calculated value of the pore solution was 11.84, with a difference of 1.3% between the measured value and the calculated value; at...

Embodiment 2

[0021] Concrete specimens are made, the size is 3×10×10mm, the cement is 42.5 grade ordinary Portland cement, and the sand is medium sand with a fineness modulus of 2.8. After the specimens were cured for 28 days under standard conditions, in CO 2 The accelerated carbonization test was carried out in an environment with a concentration of 5%, a temperature of 20°C, and a relative humidity of 40%. Concrete mix parameters: the amount of cement is 450kg / m 3 , water-cement ratio 0.5, fine aggregate consumption 650 kg / m 3 .

[0022] As the carbonization progresses, the pH value of the pore solution is related to the pH value of the suspension as follows: , and the correlation coefficient is 0.98. At 3 days of carbonization, the measured pH values of the pore solution and suspension were 12.25 and 12.37 respectively, and the calculated value of the pore solution was 12.24, with a difference of 0.1% between the measured and calculated values; at 6 days of carbonization, the me...

Embodiment 3

[0024] Concrete specimens are made, the size is 3×10×10mm, the cement is 42.5 grade ordinary Portland cement, and the sand is medium sand with a fineness modulus of 2.8. After the specimens were cured for 28 days under standard conditions, in CO 2 The accelerated carbonization test was carried out in an environment with a concentration of 5%, a temperature of 20°C, and a relative humidity of 40%. Concrete mix parameters: the amount of cement is 500kg / m 3 , water-cement ratio 0.5, fine aggregate consumption 680 kg / m 3 .

[0025] As the carbonization progresses, the pH value of the pore solution is related to the pH value of the suspension as follows: , and the correlation coefficient is 0.98. At 3 days of carbonization, the measured pH values of the pore solution and the suspension were 12.35 and 12.45 respectively, and the calculated value of the pore solution was 12.39, with a difference of 0.3% between the measured value and the calculated value; at 6 days of carboniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com