Intensive acquisition system for milk

A technology of centralized collection and milk volume, applied in signal transmission systems, instruments, etc., can solve the problems of high cost ratio of metering devices, unfavorable scientific development of dairy industry, Chinese maintenance and other problems, so as to improve milking work efficiency and facilitate large-scale The effect of promoting and simplifying field wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

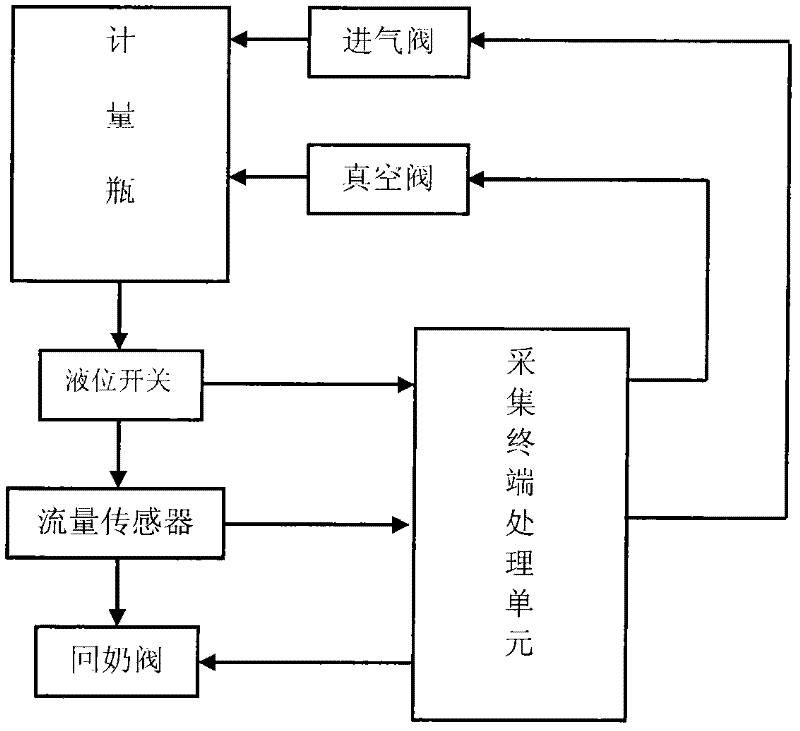

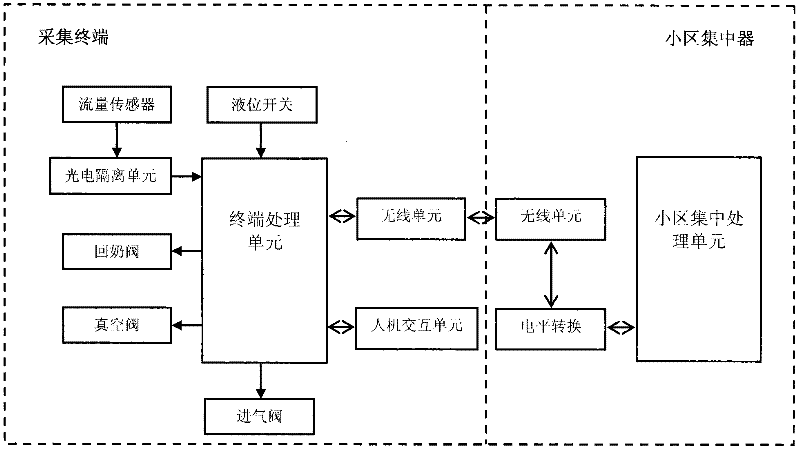

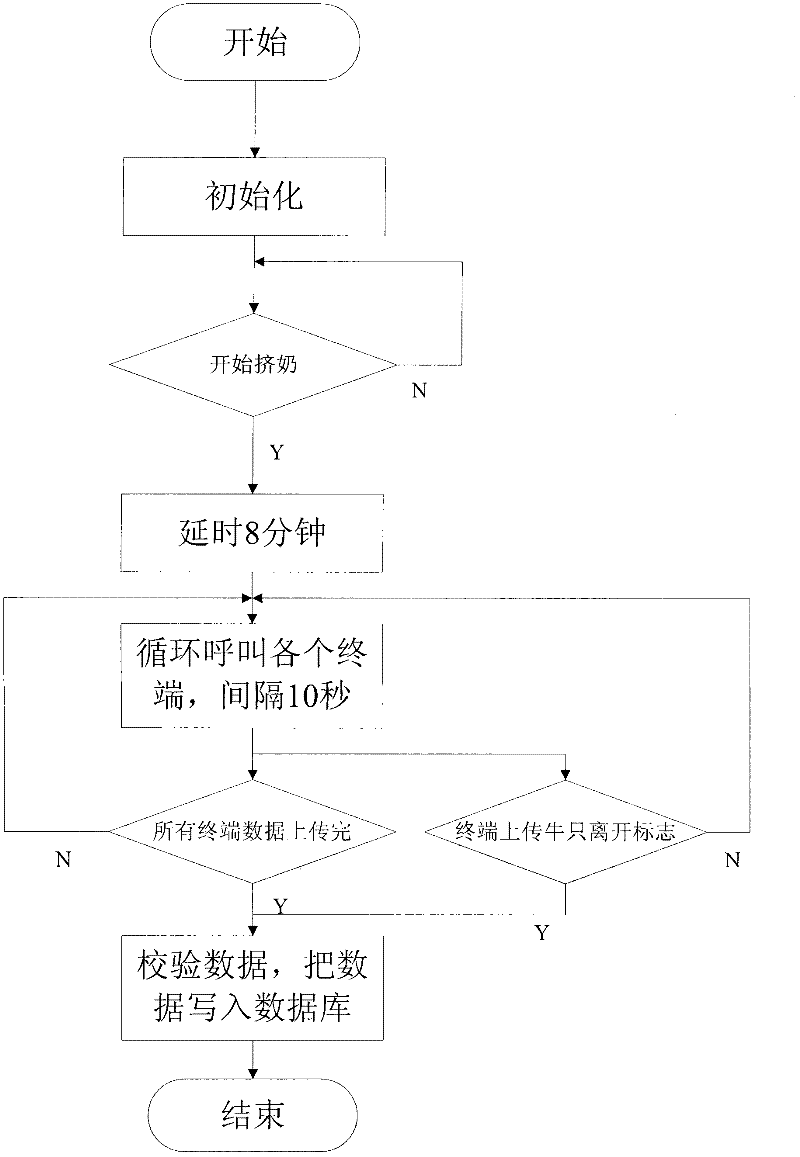

[0020] A centralized collection system for milk volume of the present invention includes a cell concentrator and a collection terminal, wherein the cell concentrator is composed of a centralized processing unit, a level conversion circuit and a wireless unit, and the collection terminal is composed of a terminal processing unit, a wireless unit, a man-machine Composed of interactive unit, milk return valve, vacuum valve, intake valve, liquid level switch, photoelectric isolation unit and flow sensor.

[0021] Described community concentrator, its centralized processing unit is host computer, and host computer processing software is installed on it, and software has the function of realizing control to collecting terminal and carrying out comprehensive processing to collected data, simultaneously software passes and actual milking operation process Combined with each other, it has a certain self-error correction function. Its input and output terminals are respectively connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com