Pad structure and manufacturing method thereof

A gold layer and nanotechnology, applied in the direction of electrical connection of printed components, formation of electrical connections of printed components, semiconductor/solid-state device manufacturing, etc., can solve problems such as insufficient wear resistance of the nickel-gold layer surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Throughout the following specification, "pad" or "pad structure" broadly refers to a bonding pad or a contact pad structure, where the bonding pad can be a wire-bond finger or a solder bond pad. ), etc., and the contact pads may include electrical contact gold fingers on the substrate, for example, external contact fingers of a DRAM, or input / output pads (input / output pads) on an integrated circuit chip, and the like. Although, in the following preferred embodiments, the exposed electrical contact or pad structure on the circuit board or package substrate is used as an example for illustration, the present invention is not limited to these application fields, but should be based on the attached The scope of the invention is defined by the claims.

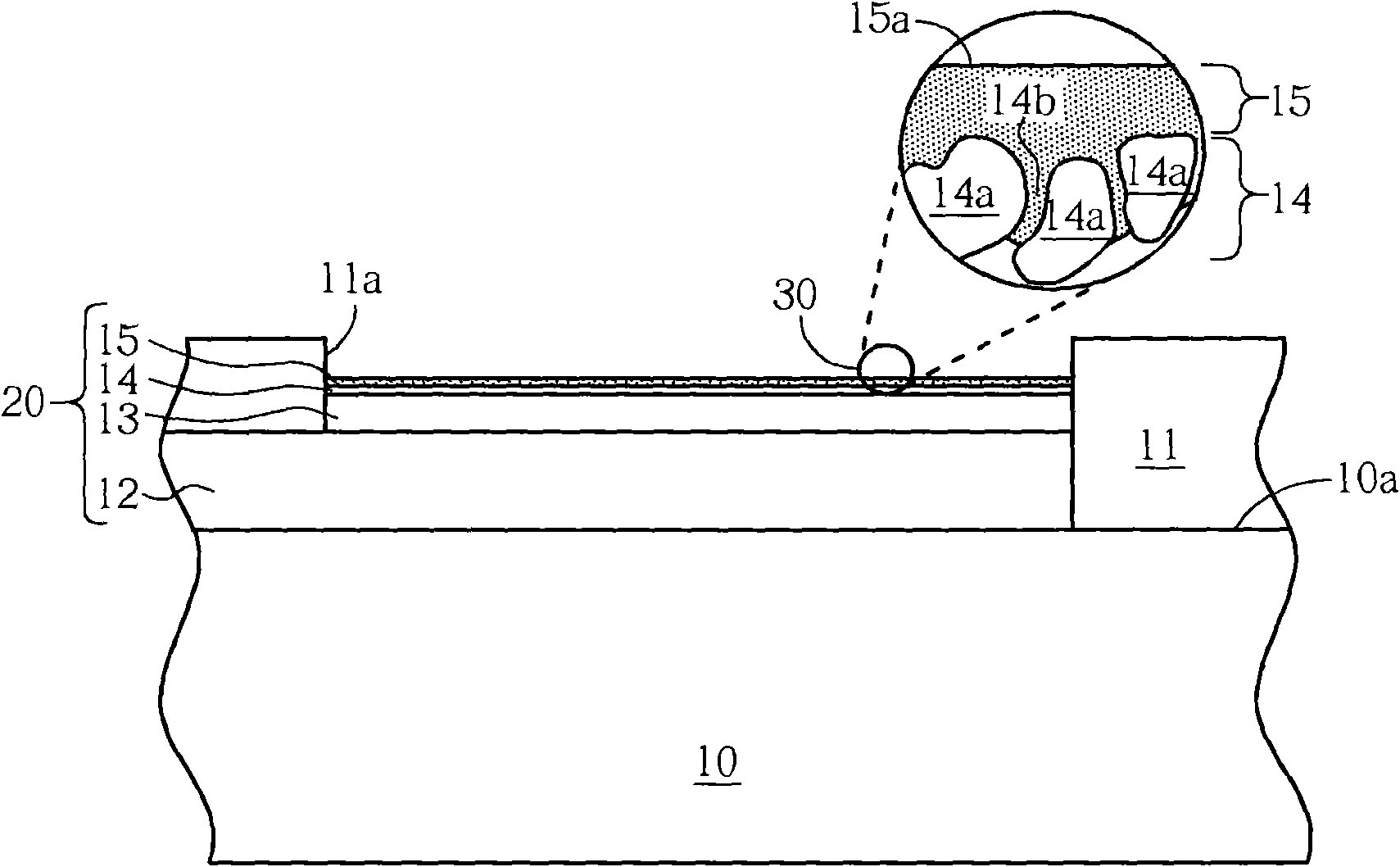

[0038] Please refer to figure 1 , which is a schematic cross-sectional view of a pad structure according to a preferred embodiment of the present invention. Such as figure 1 As shown, according to the preferred embodiment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com