Multipurpose capsule

A multi-purpose, capsule technology, applied in the directions of transportation and packaging, can solve the problems of waste of resources, inability to brew coffee powder completely, etc., and achieve the effects of good sealing performance, simple and reasonable structure, and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

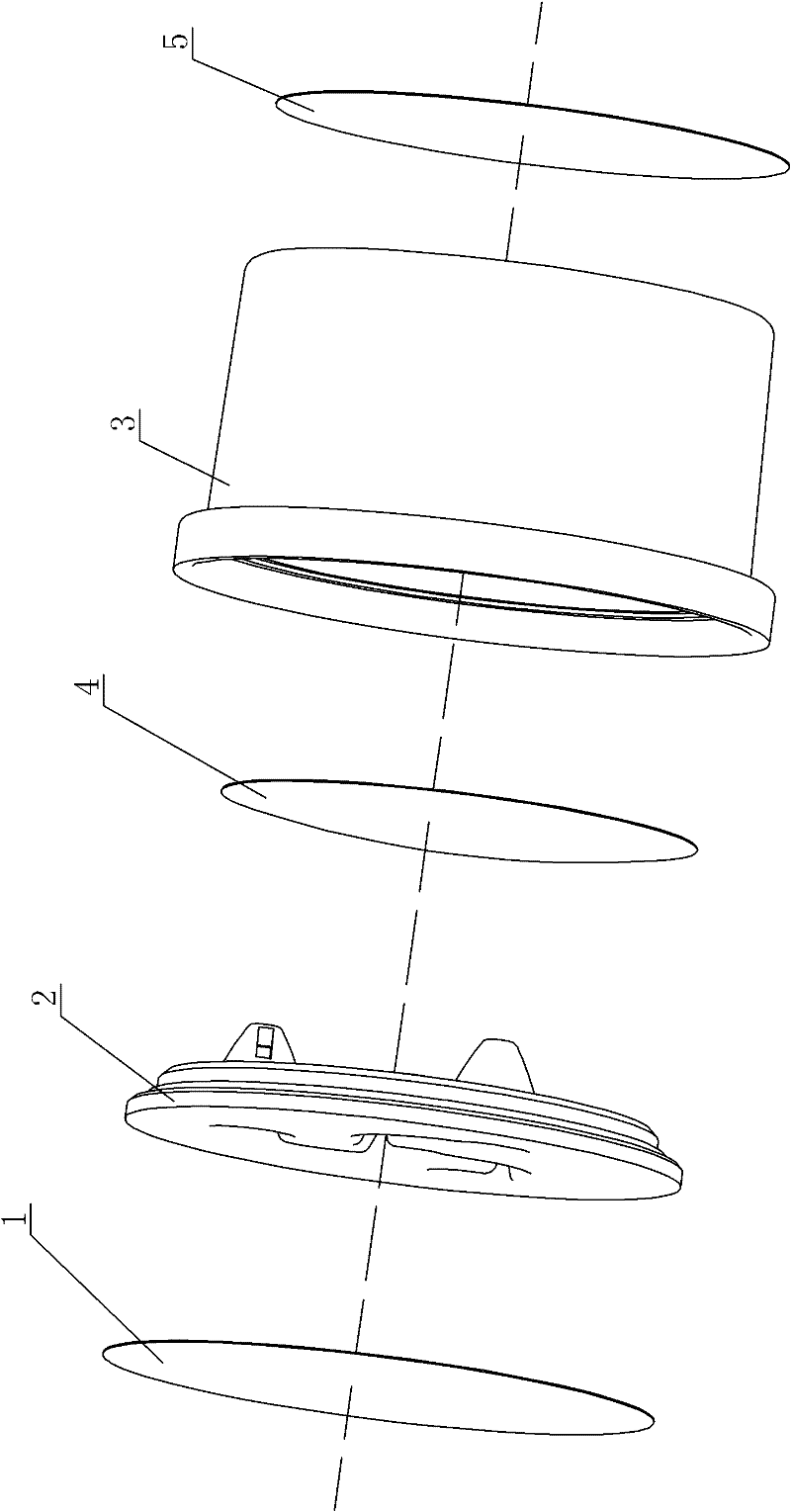

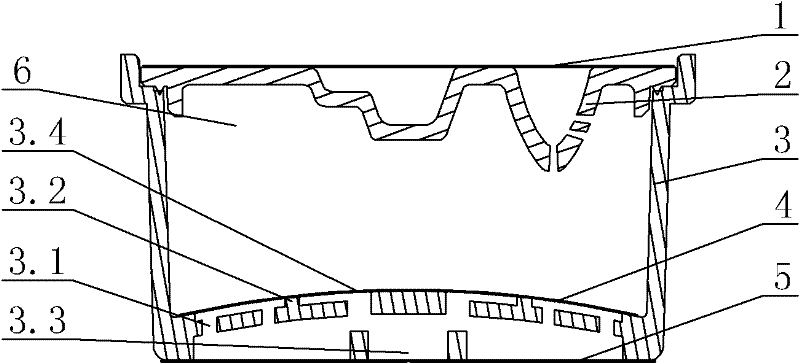

[0022] see Figure 1-Figure 4 , The multi-purpose capsule includes a capsule body 3 and a capsule cover 2 tightly covered thereon, both of which form a cavity 6, which can be used to hold coffee, tea leaves and the like for preparing beverages. The bottom of the capsule body 3 is provided with a water outlet 3.3, and the top of the capsule cover 2 is provided with a water inlet 2.3, and three flow channels 2.1 extend from the water inlet 2.3, and the flow channels communicate with the cavity 6.

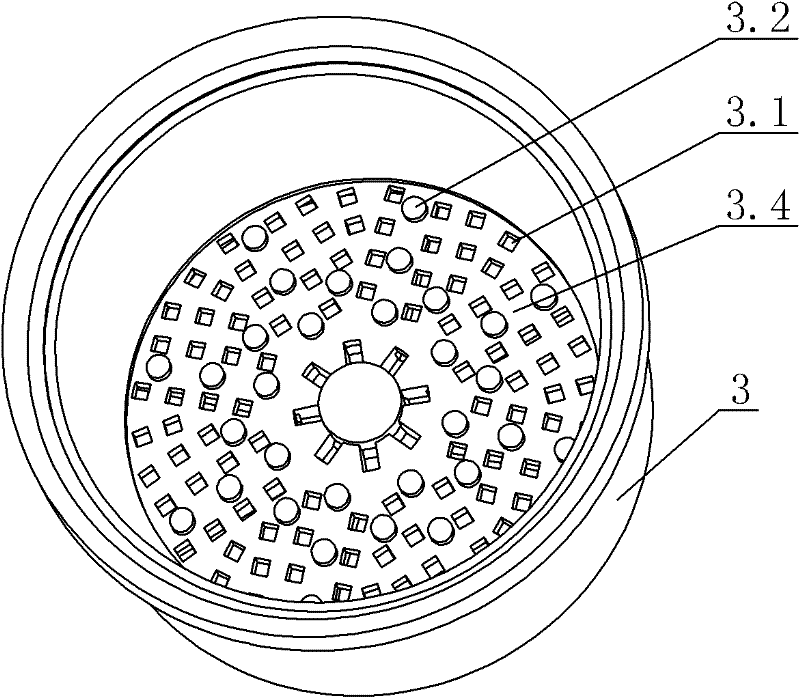

[0023] see image 3 The inner bottom surface 3.4 of the capsule main body 3 is a convex spherical surface, the inner bottom surface is evenly distributed with small holes 3.1, the small holes communicate with the cavity 6, and the small holes 3.1 are also provided with convex bumps 3.2 at intervals. The point 3.2 is covered with filter paper 4 that blocks the inner bottom surface 3.4, and the convex point 3.2 supports the filter paper 4 to prevent the filter paper from blocking the s...

no. 2 example

[0027] see Figure 5 , this multi-purpose capsule, its capsule cover 2 is compared with the first embodiment, and the main difference is that it is set on the capsule water inlet 2.2 and the shower hole 2.22 with smaller aperture and more holes is connected with the cavity 6, and the shower hole 2.22 Compared with the brewing hole 2.21, when the former is working, the sprayed water flow column is more, denser, and wider in range, and the contact with the brewing material in the capsule main body 3 is more sufficient, so that the brewing is more sufficient. Its flow channel 2.1 can adopt inline shape, wave shape, or right angle shape. Other unmentioned parts are the same as the first embodiment.

no. 3 example

[0029] see Figure 6 , this multi-purpose capsule, its capsule cover 2 compares first embodiment, and main difference is that its water inlet end 2.3 is positioned at one side of capsule cover 2; The one-shaped flow channel 2.1, the angle between the flow channels 2.1 is 60 degrees, the flow channel 2.1 can disperse the water flowing through the water inlet 2.3 into multiple streams, and set the water inlet 2.2 of the capsule with a smaller aperture, The shower holes 2.22 with more holes are injected into the cavity 6 . It enters water from one side of the capsule cover 2, so that when brewing, the brewed matter in the capsule main body 3 will be rolled by the washing of the water flow, so as to make the brewing more sufficient. The runner 2.1 can also be arc-shaped, wave-shaped, or right-angled. Other unmentioned parts are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com