Method for folding plain edges of shuttleless glass fiber cloth

A technology of glass fiber cloth and glass fiber, which is applied in the field of hemming of shuttleless glass fiber edging cloth, can solve the problem that the warp force, weft force and thickness appearance of the glass fiber cloth cannot be satisfied, and the burr of the glass fiber cloth cannot be solved. problems, glass fiber has no elasticity, etc., to achieve the effect of improving labor efficiency, reducing friction, and improving operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In conjunction with the accompanying drawings, the following embodiments of the present invention are given: but the present invention is not limited to the following embodiments.

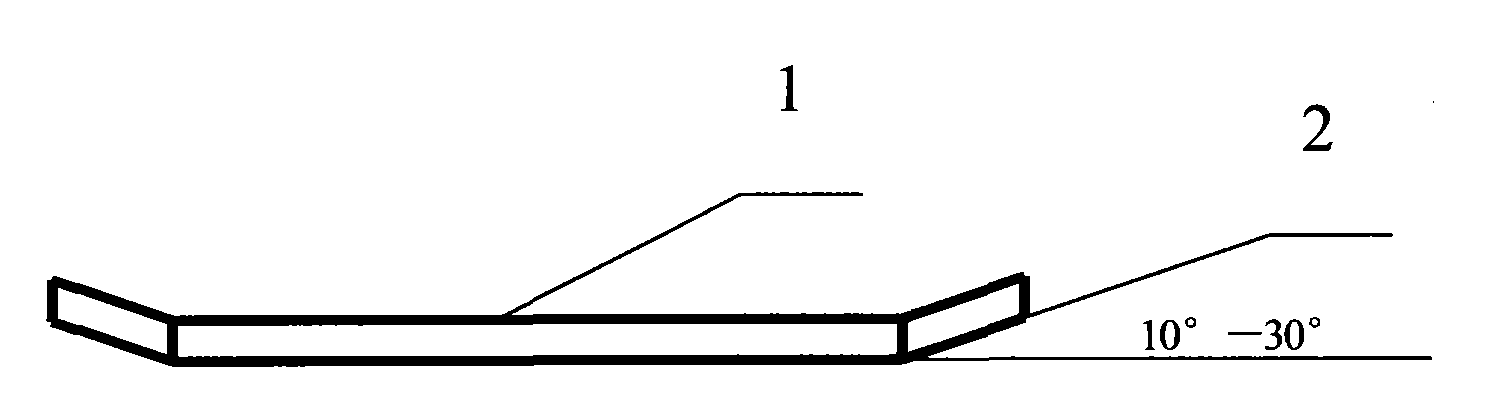

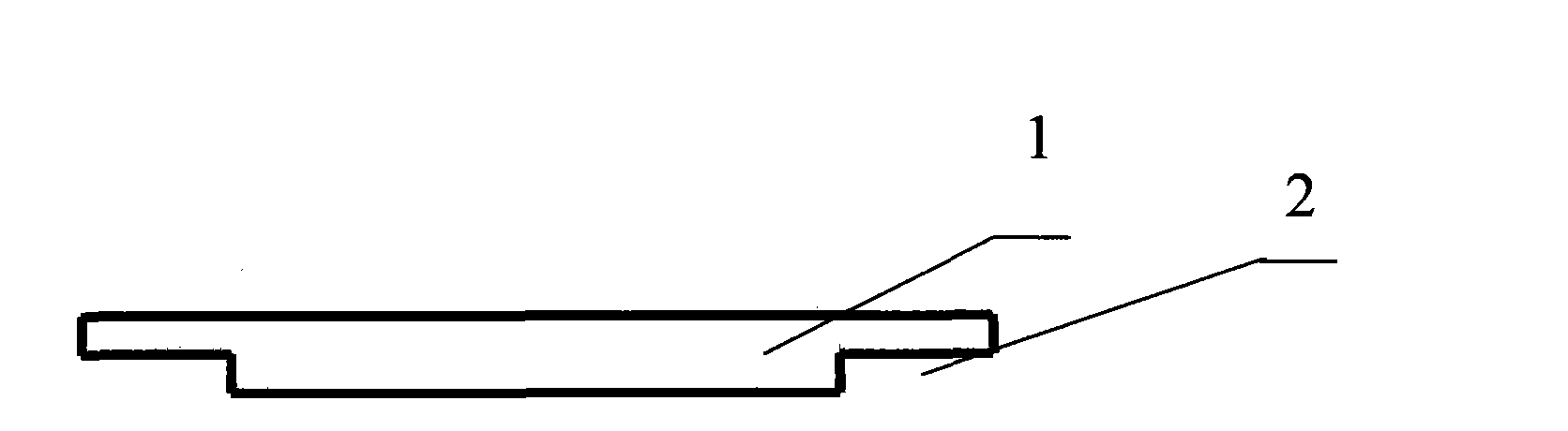

[0014] The shuttleless glass fiber fabric edge folding method of the present invention is to arrange a support plate 1 at the weaving opening position of the existing shuttleless glass fiber loom, and the both ends of the support plate 1 have an upwardly inclined inclination angle. 2 Play the role of holding up and serving as a cloth temple, with an inclination angle of 10-30 degrees (such as Figure 1-2 shown).

[0015] The weaving of glass fiber cloth is still a traditional textile process, and the hemming (bright edge) part on both sides of the glass fiber cloth cloth adopts the modified twill weave weaving process. The number of said folded (bright edge) glass fiber yarns is 30 each. The selection of the number of folded glass fiber yarns is determined after repeated trials, because le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com