Safety rope weaving machine

A rope braiding machine, safe technology, applied in braided fabrics, textiles and papermaking, etc., can solve problems such as lack, and achieve the effects of reduced processing costs, simple structure, and low processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific implementation plan

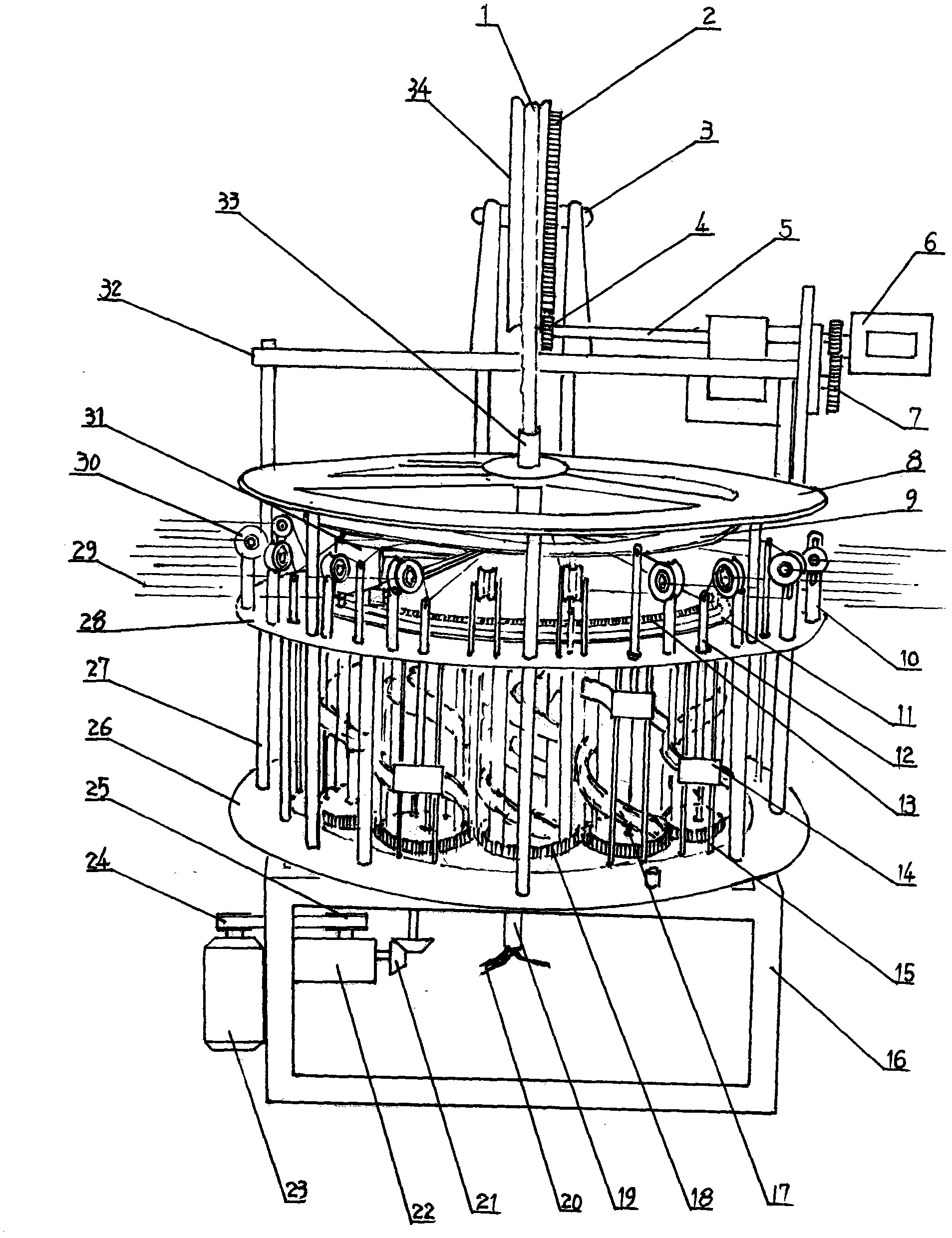

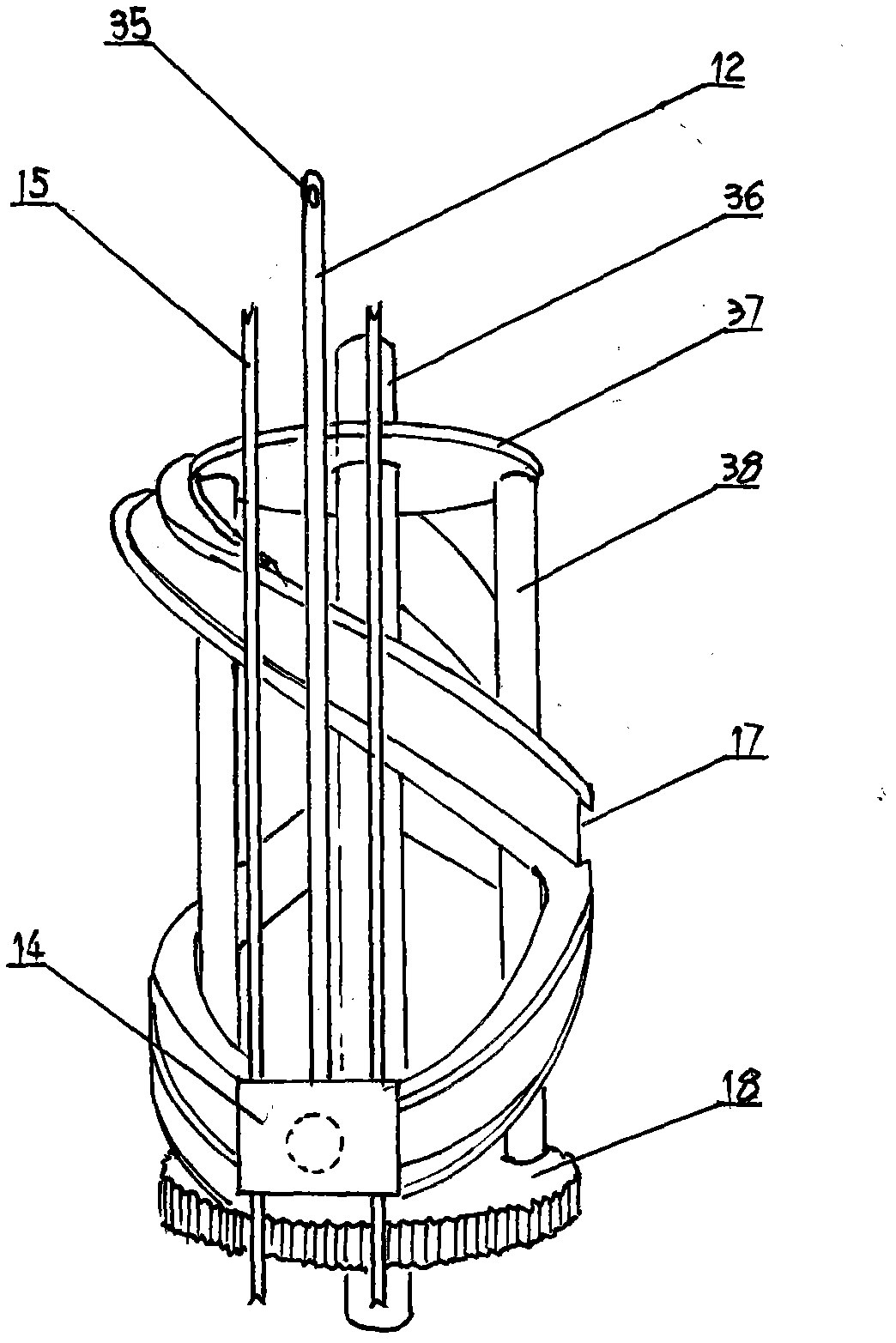

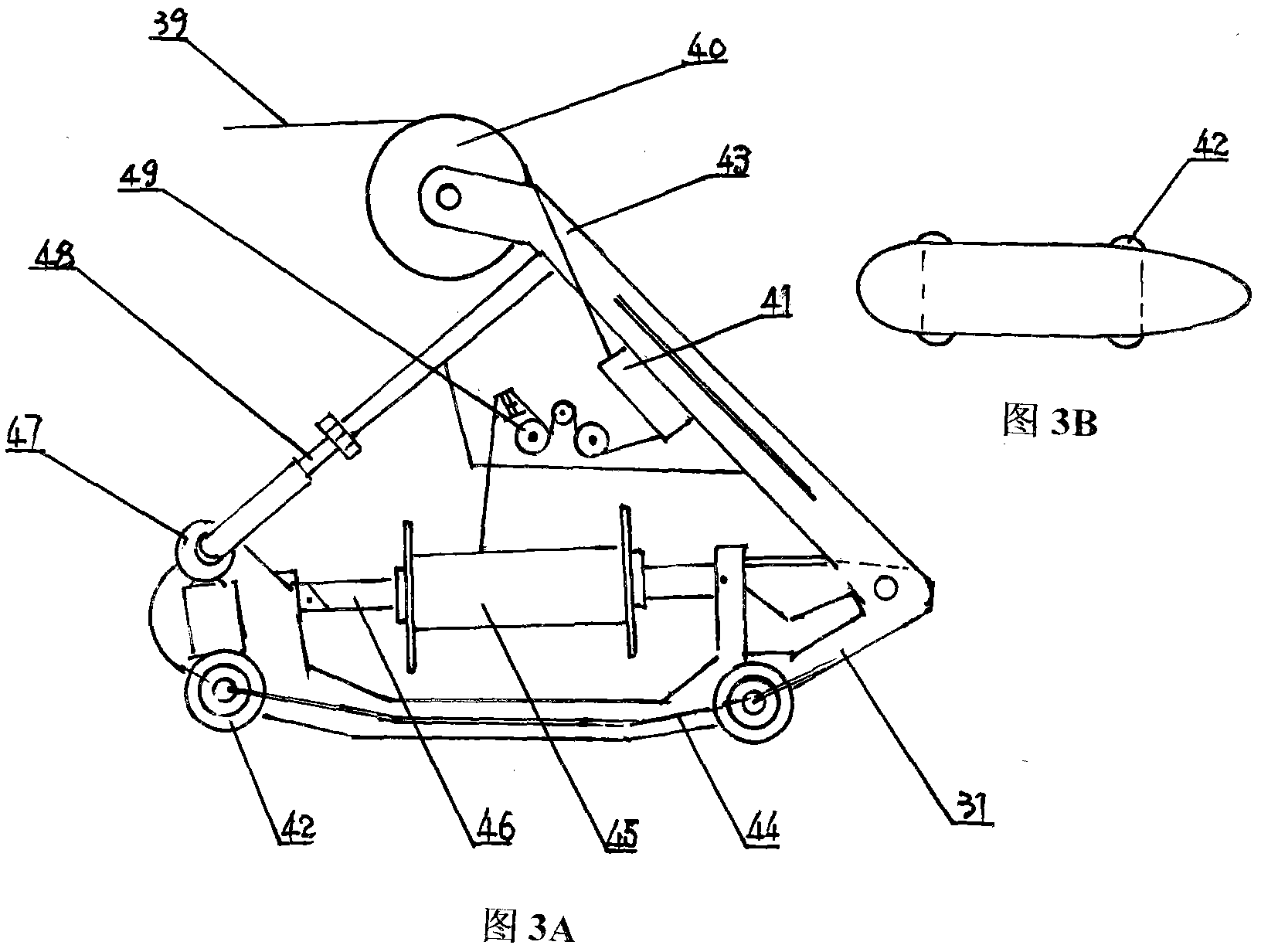

[0021] Such as Figure 1 to Figure 5 As shown, a safety rope knitting machine mainly consists of a motor 23, a conveyor belt 24, a base frame 16, a disc drive gear set 7, a traction lead wheel 34 and an upper table 8. The safety rope knitting machine includes a rope traction and lead-out device located at the upper end of the upper table, a warp wire braiding and rope grouping mechanism between the upper and middle tables, and a warp splitting rod up and down moving mechanism between the middle and lower tables. The motors driving the disk wheel transmission gear set 7, each transmission gear pair 21 and the gear transmission box 22 are all fixed on the chassis. The motor drives the input end 25 of the gear transmission box through the conveyor belt. There can be multiple output ends of the gear transmission box, which provide power of different speeds for each transmission gear pair. This is a traditional technology, so it will not be repea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com