Magnetic liquid sealing device with heating by electromagnetic waves

A magnetic liquid and sealing device technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of shaft speed reduction and safety performance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described with accompanying drawing as specific embodiment:

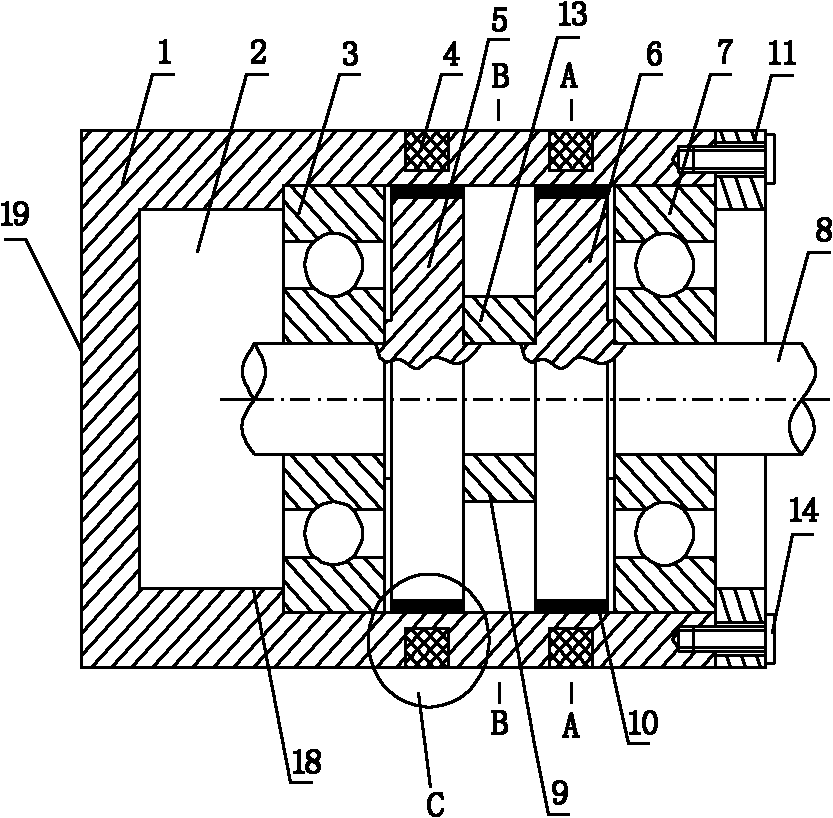

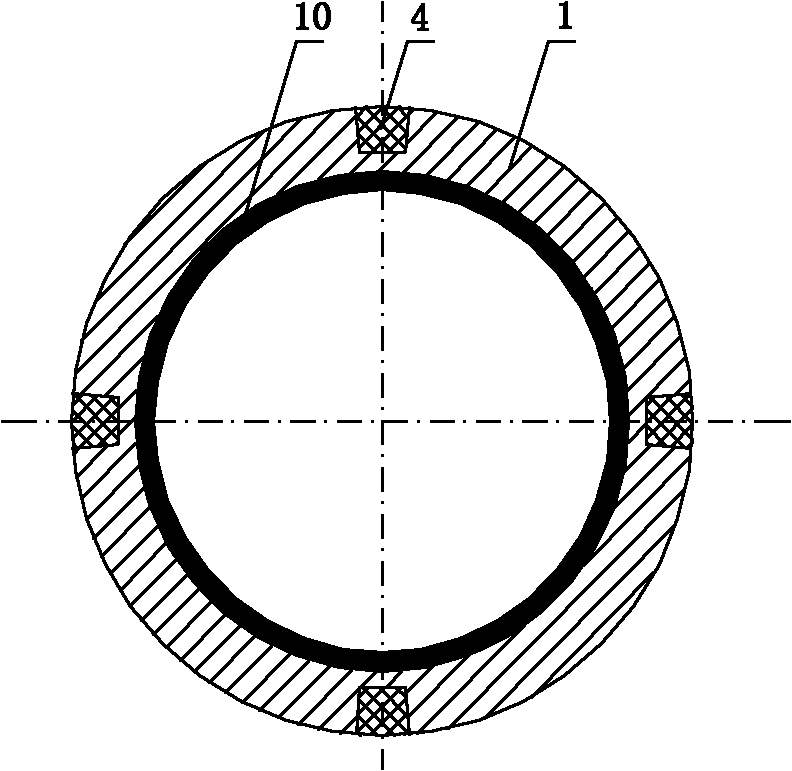

[0025] A magnetic liquid sealing device with electromagnetic wave heating, such as figure 1 , the sealing device includes: a metal sleeve, a sealing space, a bearing, a pole piece, a transmission shaft, a permanent magnet, a magnetic fluid, and a screw.

[0026] The transmission shaft 8 of the sealing device, such as Figure 5 , it is a stepped shaft including the first shaft shoulder 15, the first pole piece 5, the intermediate shaft diameter 17, the second pole piece 6 and the second shaft shoulder 16; the first pole piece 5 and the second pole piece 6 are transmission shafts 8 steps with the same outer diameter and thickness.

[0027] The first bearing 3 is installed on the first shaft shoulder 15 of the drive shaft, such as figure 1 and Figure 5 .

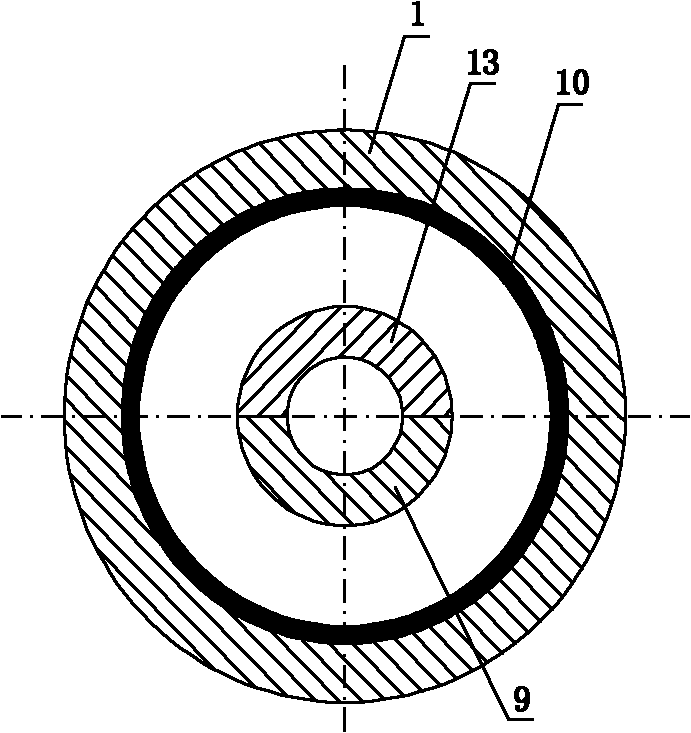

[0028] The first permanent magnet 13 and the second permanent magnet 9 are semicircular rings with the same struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com