Electric locomotive device system for generating and charging by vacuum energy

An electric locomotive and vacuum technology, applied in the direction of generators/motors, electromechanical devices, electric vehicles, etc., can solve the problems of self-charging, etc., and achieve the effects of easy storage, easy implementation and popularization, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

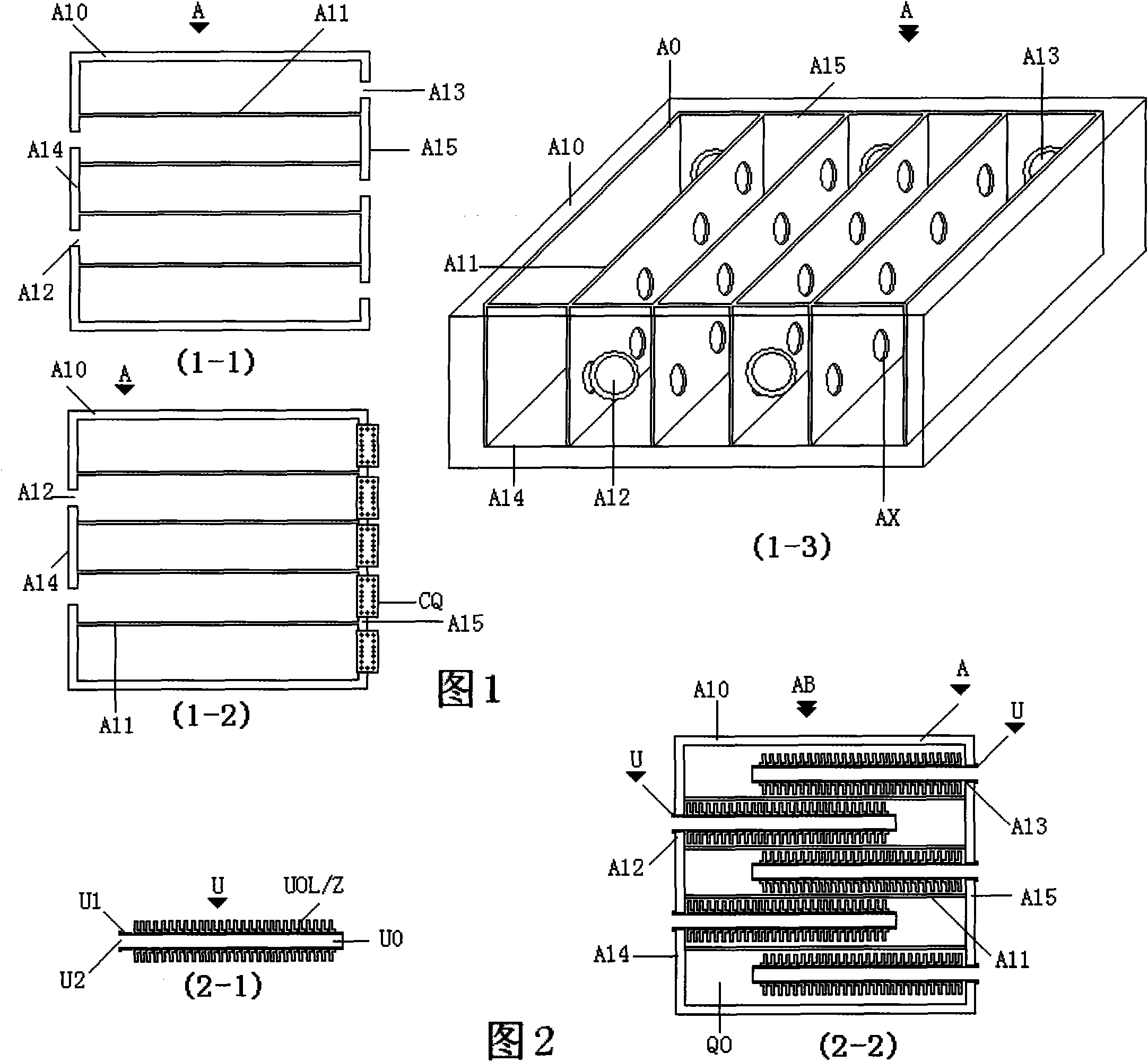

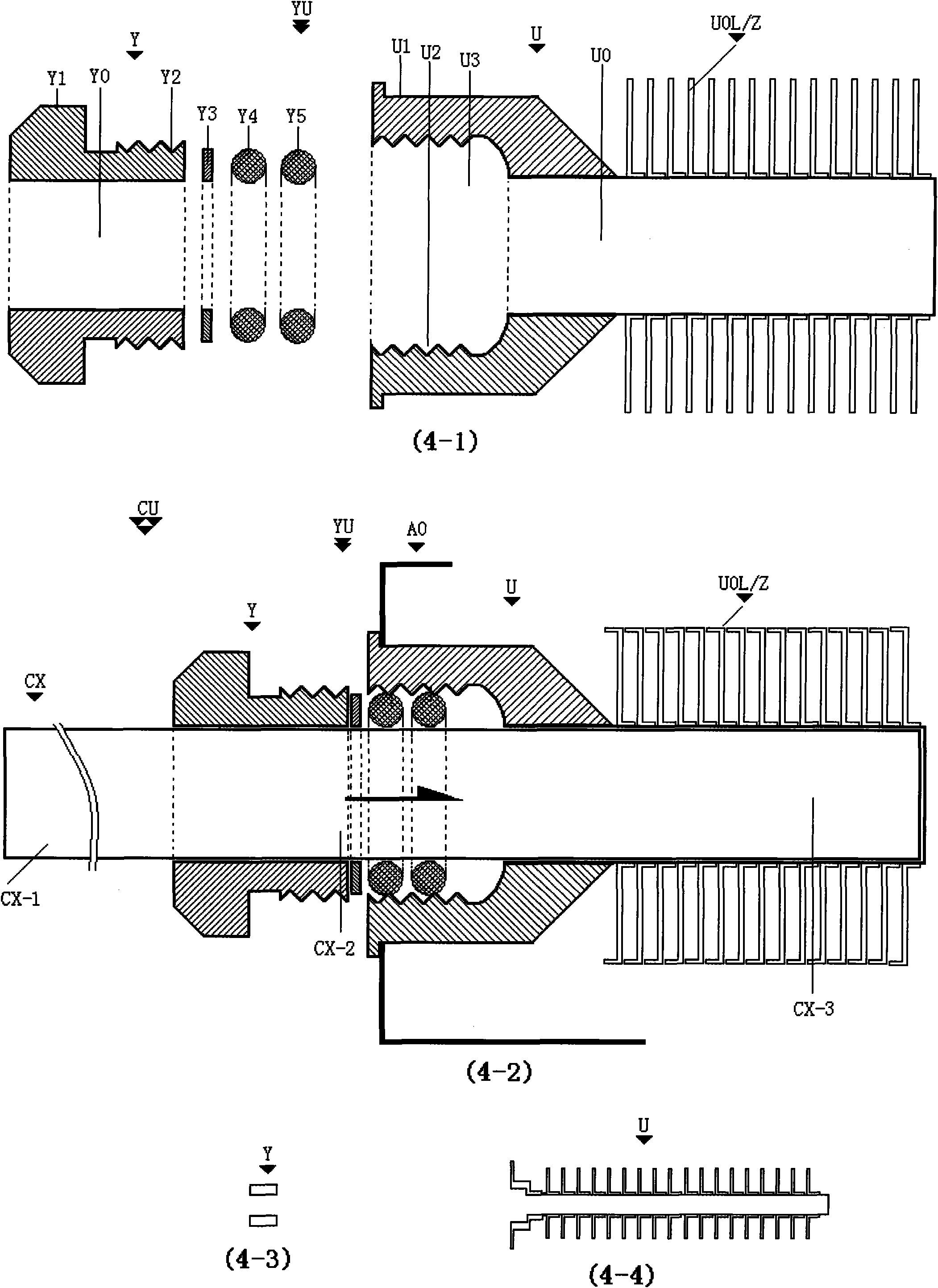

[0107] exist figure 1 , 2 , 3 middle: heat source box (A), vacuum shell (A10), vertical hole spacer (A11), casing hole (A12), casing hole (A13), front box plate (A14), rear box plate ( A15), rectangular vacuum energy pump (CQ); vacuum energy storage heat source box (AB), casing (U), nut seat (U1), internal thread (U2), U-shaped tube (U0), fin (U0L / Z), heat gathering source box (A), vacuum energy liquid (Q0); rectangular pump (CQ), heat gathering source vacuum energy pump box (ABC), heat gathering source box (A), heat gathering source vacuum energy pump (C1), Heat source vacuum energy pump (C2), vacuum shell pump (C3), energy gathering end (C1-1), energy gathering end (C2-1), energy gathering end (C3-1), energy transmission section (C1-2 ), energy transmission section (C2-2), energy transmission section (C3-2), energy dissipation end (C1-3), energy dissipation end (C2-3), energy dissipation end (C3-3), bushing ( U), front box plate (A14), rear box plate (A15), rectangular v...

Embodiment 2

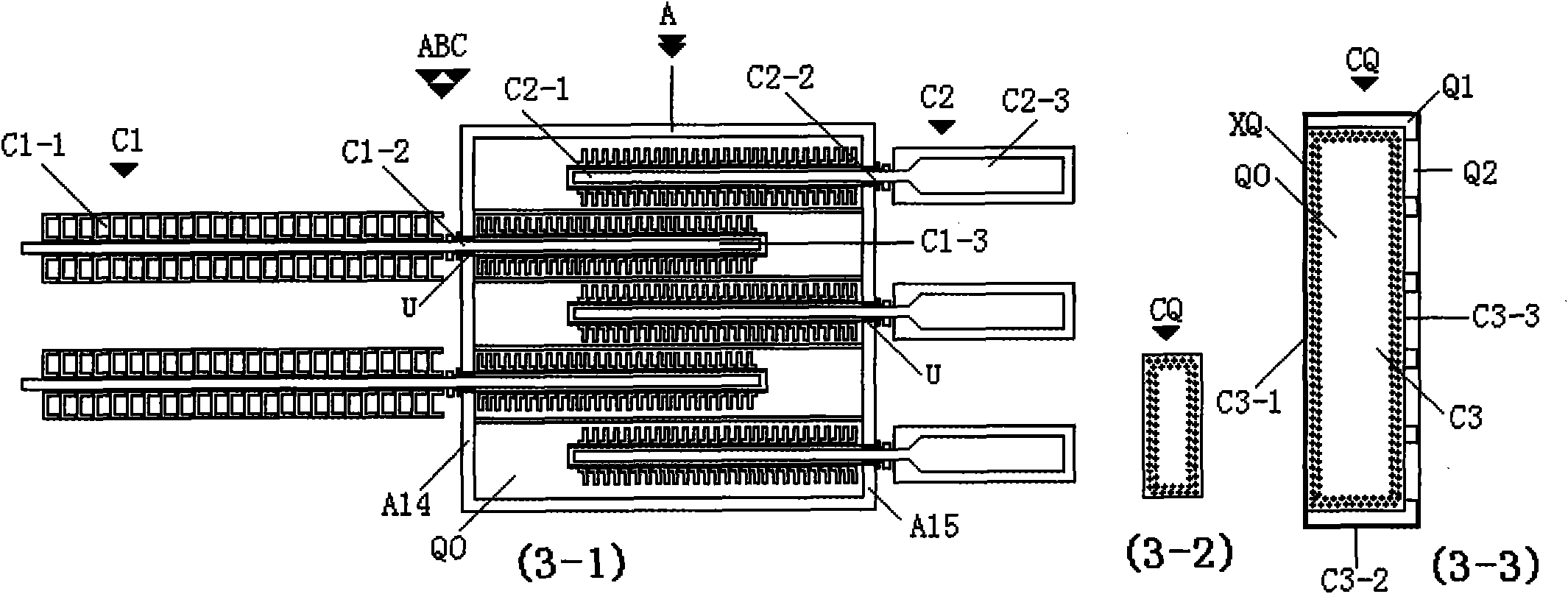

[0114] exist Figure 4 Middle: pump casing (YU), pump bolt (Y), round hole (Y0), bolt handle (Y1), external thread (Y2), gasket (Y3), rubber ring (Y4), rubber ring (Y5), Sleeve (U), nut seat (U1), internal thread (U2), inner hole (U3), U-shaped tube (U0), fins (U0L / Z), vacuum energy pump (CX), energy gathering end ( CX-1), energy transmission section (CX-2), energy dissipation end (CX-3), outer box tube (A0).

[0115] In the figure: the pump casing (YU) consists of the casing (U) connected by the pump pin (Y);

[0116] The pump bolt (Y) is composed of a bolt handle (Y1) with a round hole (Y0) and an external thread (Y2); and a gasket (Y3), an apron (Y4), and an apron sleeve (Y5) are used in the vacuum energy pump (CX) outside the energy gathering end (CX-1), energy transmission section (CX-2) or energy dissipation end (CX-3);

[0117] The sleeve (U) is connected by a U-shaped tube (U0) connected by a nut seat (U1) with an inner hole (U3) and an internal thread (U2) and a fi...

Embodiment 3

[0120] exist Figure 5 , 6 , 7 and 8: bushing heat accumulation box (AB), rectangular vacuum energy pump (CQ), vacuum shell (Q1), concave frame (Q2), convex frame (Q3), vacuum energy liquid (Q0), Sintering layer (XQ), heat-gathering vacuum energy pump (C), energy-gathering end (C-1), energy transmission section (C-2), energy-dissipating end (C-3), vacuum energy liquid (Q0), sintering Layer (XQ), Comb Right Angle (LE1), Comb Right Angle (LE2), Casing Heat Collector Box (AB), Back Box Plate (A15), Energy Isolation Surface (QQ); Vertical Pump (CQC1), Single Soft Pump (CQC2), double soft pump (CQC2), pump vacuum shell (QQ), energy transmission section (CQC-2), energy gathering end (CQC-1), hose section (CS), hose section (CS1), Hose section (CS2); type 3 pump generator (CQ-3A), type 6 pump generator (CQ-3B), vacuum energy pump (CQC), energy transmission section (CQC-2), pump hole (Q0) , pump generator (CQ-3B), vacuum shell (Q1), concave frame (Q2), convex frame (Q3), rear end (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com