Complete device of spiral corrugated steel pipe and method for producing spiral corrugated steel pipe

The technology of corrugated steel pipe and complete set of equipment is applied to the field of spiral corrugated steel pipe production by complete equipment of spiral corrugated steel pipe.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

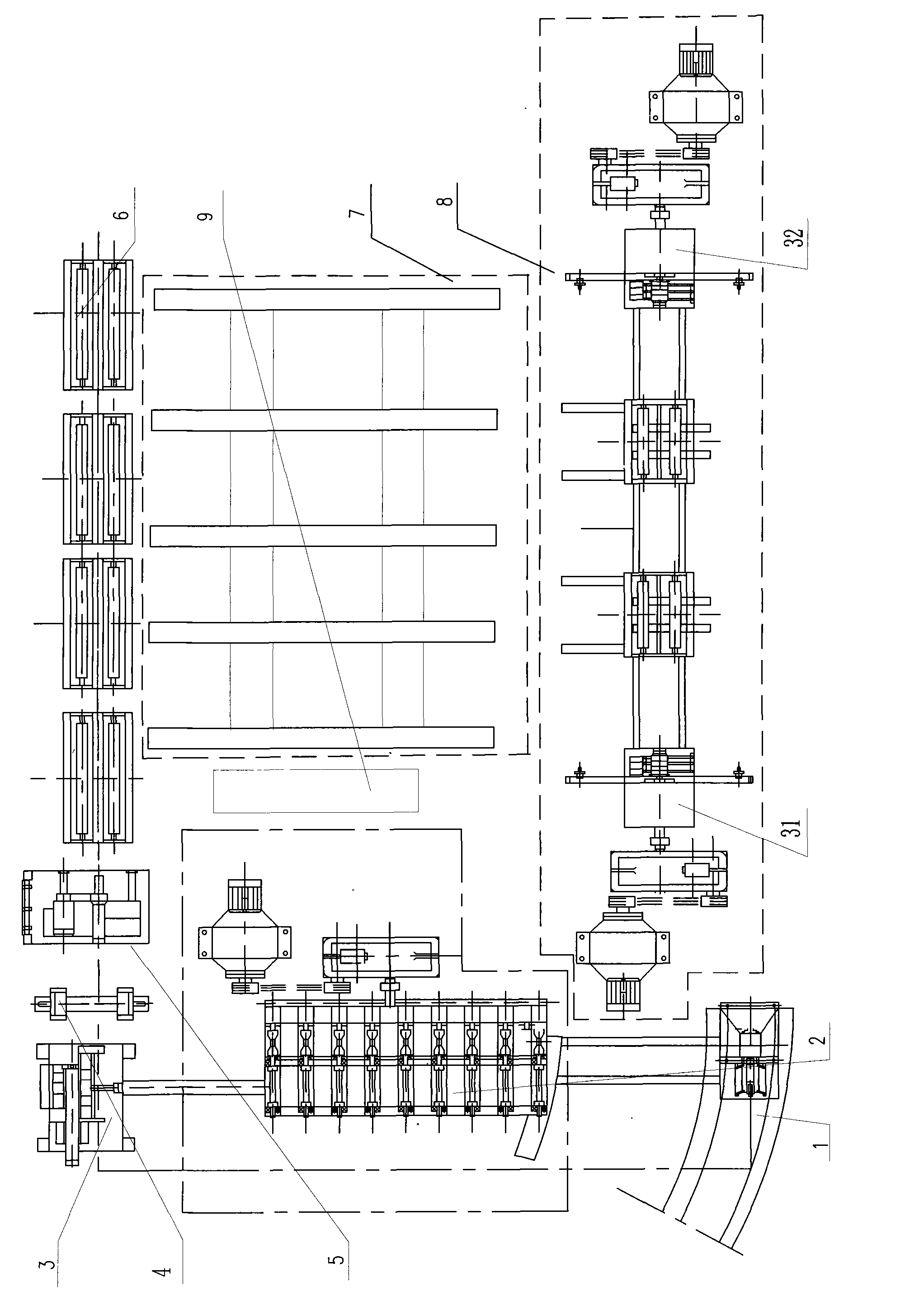

[0034] A complete set of equipment for spiral corrugated steel pipes, which consists of: an unwinding machine 1, the outlet of the unwinding machine 1 is connected to the inlet of the forming machine 2, the outlet of the forming machine 2 is connected to the inlet of the forming machine 3, and the forming machine 3 outlets are connected to transition bracket 4 inlets, said transition bracket 4 outlets are connected to cutting saw 5 inlets, said cutting saw 5 outlets are connected to four sets of turning brackets 6 inlets, and said turning bracket 6 outlets are connected to conveying trays The entrance of the frame 7 and the outlet of the conveying bracket 7 are connected to the entrance of the end modification device 8. After the outlet of the end modification device, the pipe material completes the processing process, and the above processes are controlled by the console 9.

Embodiment 2

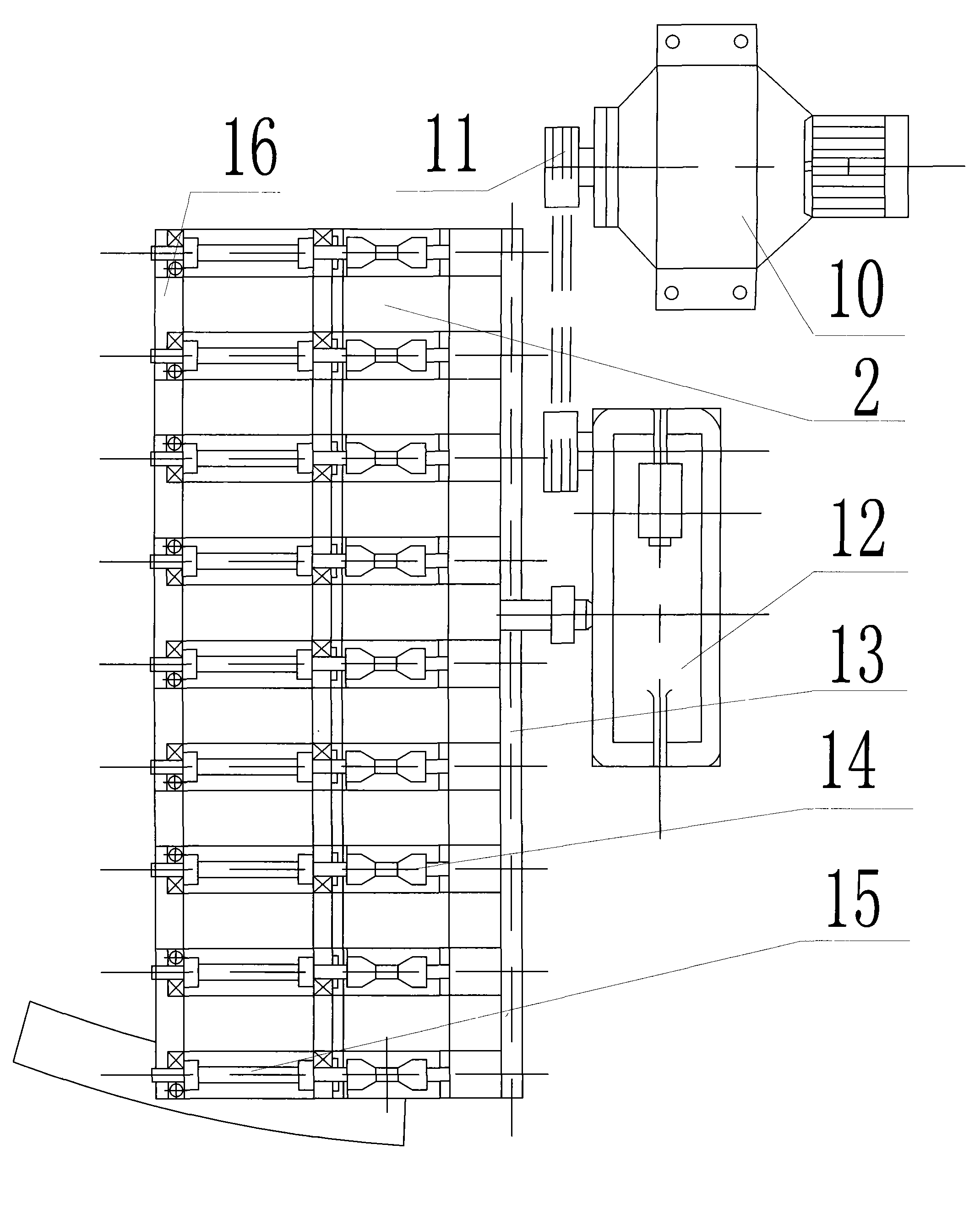

[0036] In the complete set of equipment for spiral corrugated steel pipes described in Example 1, the pressing machine 2 includes a motor 10, a V-belt transmission assembly 11 connected to the motor, a reduction box 12 connected to the V-belt transmission assembly 11, The gear box 13 connected to the reduction box 12 , the universal joint drive 14 connected to the gear box 13 , and the pressure roller group 15 installed on the frame 16 connected to the universal joint drive 14 .

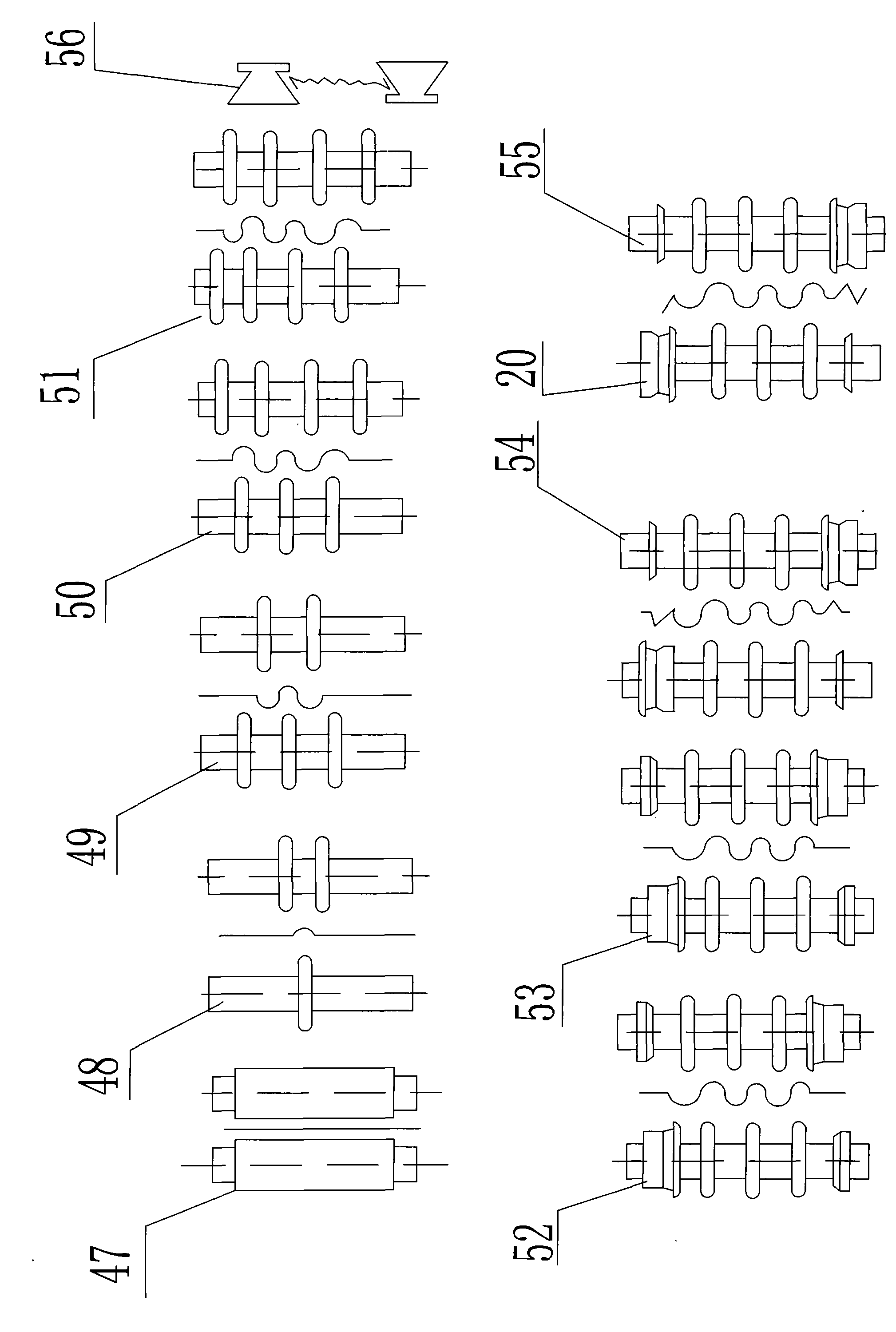

[0037] The complete set of equipment for the spiral corrugated steel pipe, the pressure roller set has different pressure wheel sets, the pressure pressure wheel set 15 has a roller shaft 17, and the roll shaft 17 penetrates the pressure shape wheel 18, The profile pressing wheel 18 is connected to the hemming wheel 20 through the spacer sleeve 19, and the frame is connected to the shaping and cornering wheel set 56.

Embodiment 3

[0039] In the complete set of equipment for spiral corrugated steel pipes described in Example 1, the forming machine 3 has a spiral crimping device 21 and a bite forming device 22, and the spiral crimping device includes a transitional forming wheel set 28, forming Circular pressure forming wheel set 25 and sizing pressure forming wheel set 27. The bite forming device 22 has an upper snapping wheel 26 and a lower snapping wheel 24. The forming machine frame 23 is connected to the transitional pressing wheel set 28, become circle pressing shape wheel set 25, sizing pressure shape wheel set 27 and last snapping wheel 26 and following snapping wheel 24.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap