Self-weight thermal forming process for titanium alloy thin-wall cylindrical part

A thin-walled tube and titanium alloy technology, which is applied in the field of self-gravity thermoforming of titanium alloy thin-walled cylindrical parts, can solve the problems of easy wrinkling on the surface of parts, complex tooling structure, high manufacturing cost, etc., and achieve short development and service cycles , huge technological innovation value, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

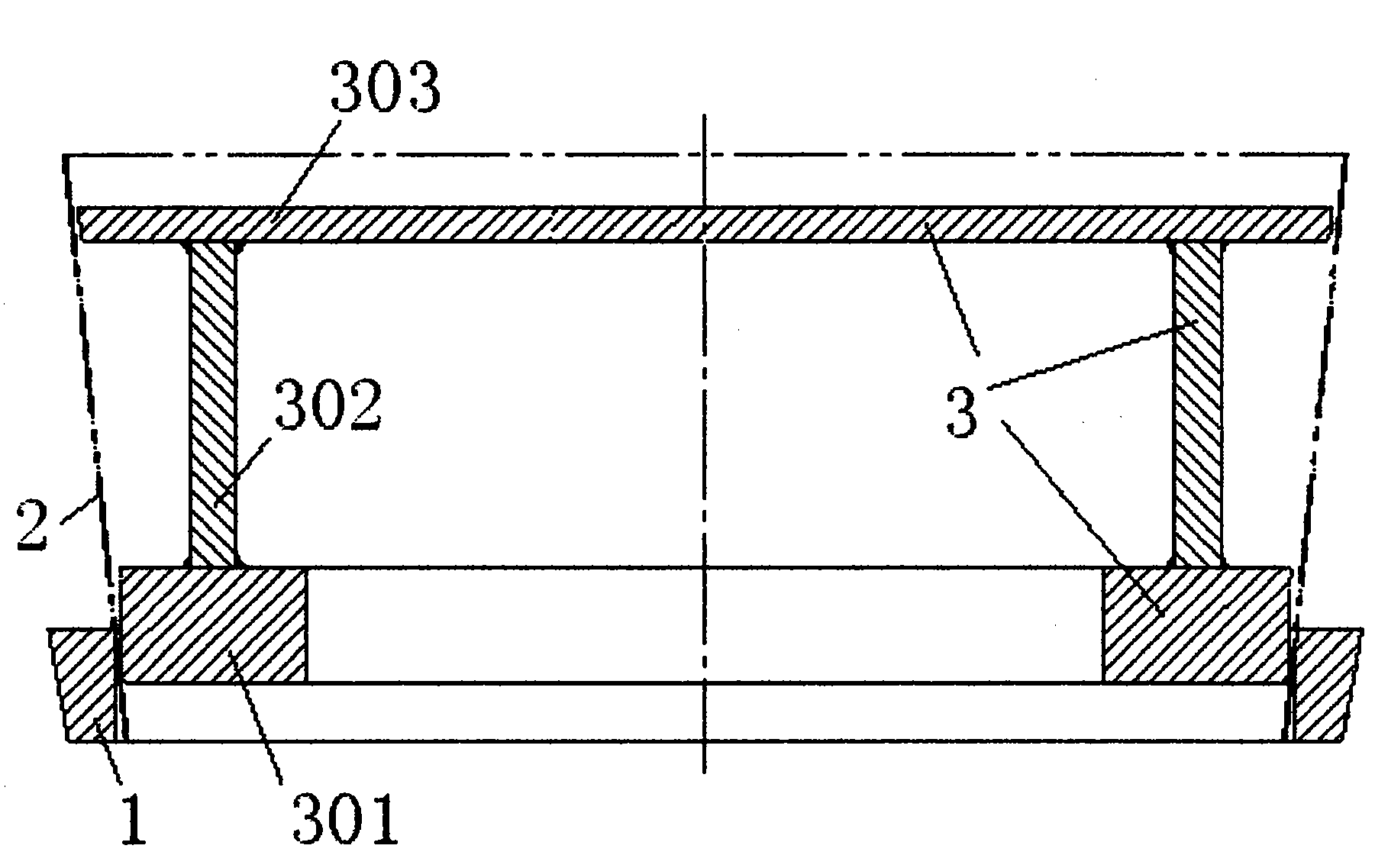

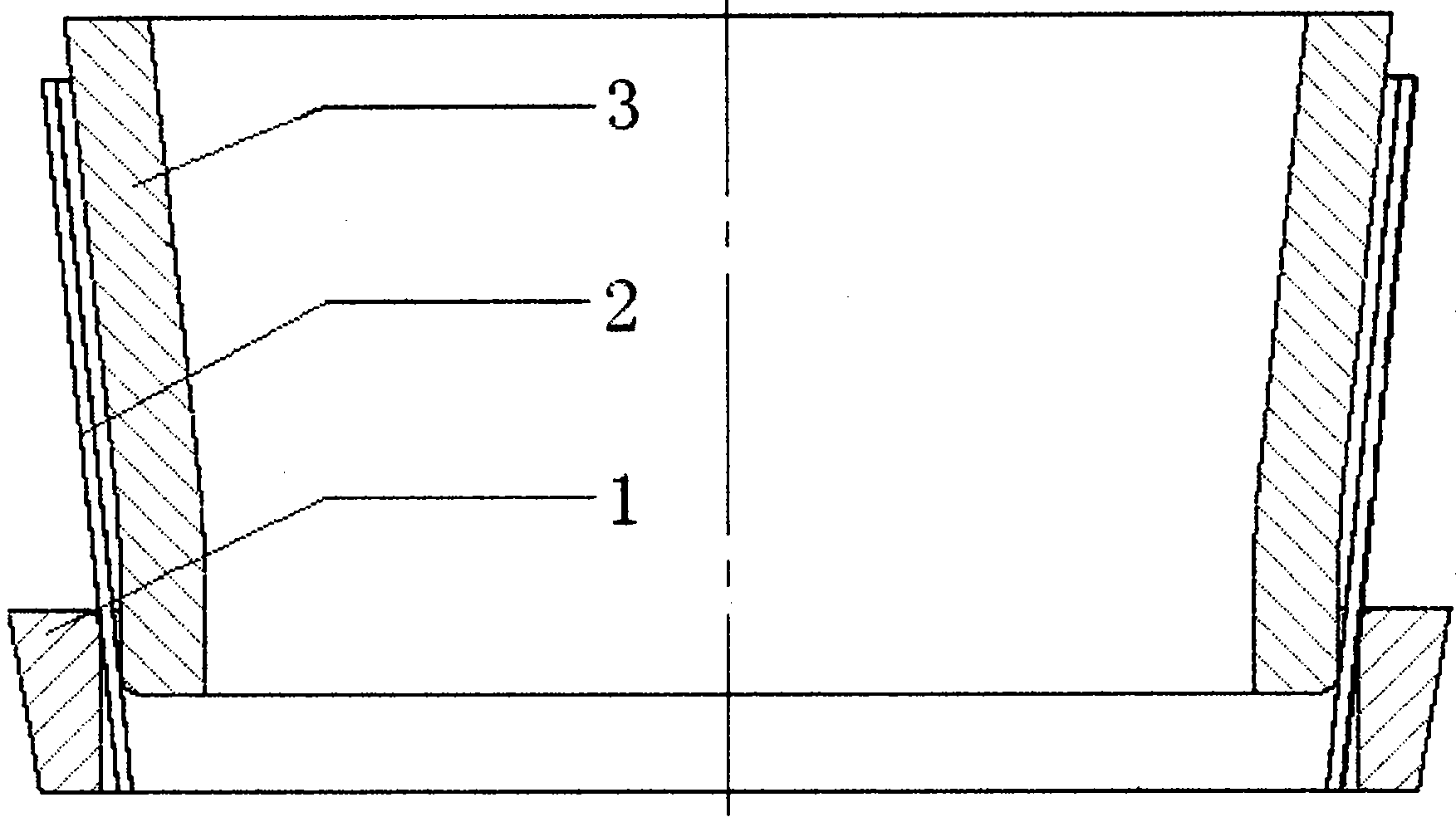

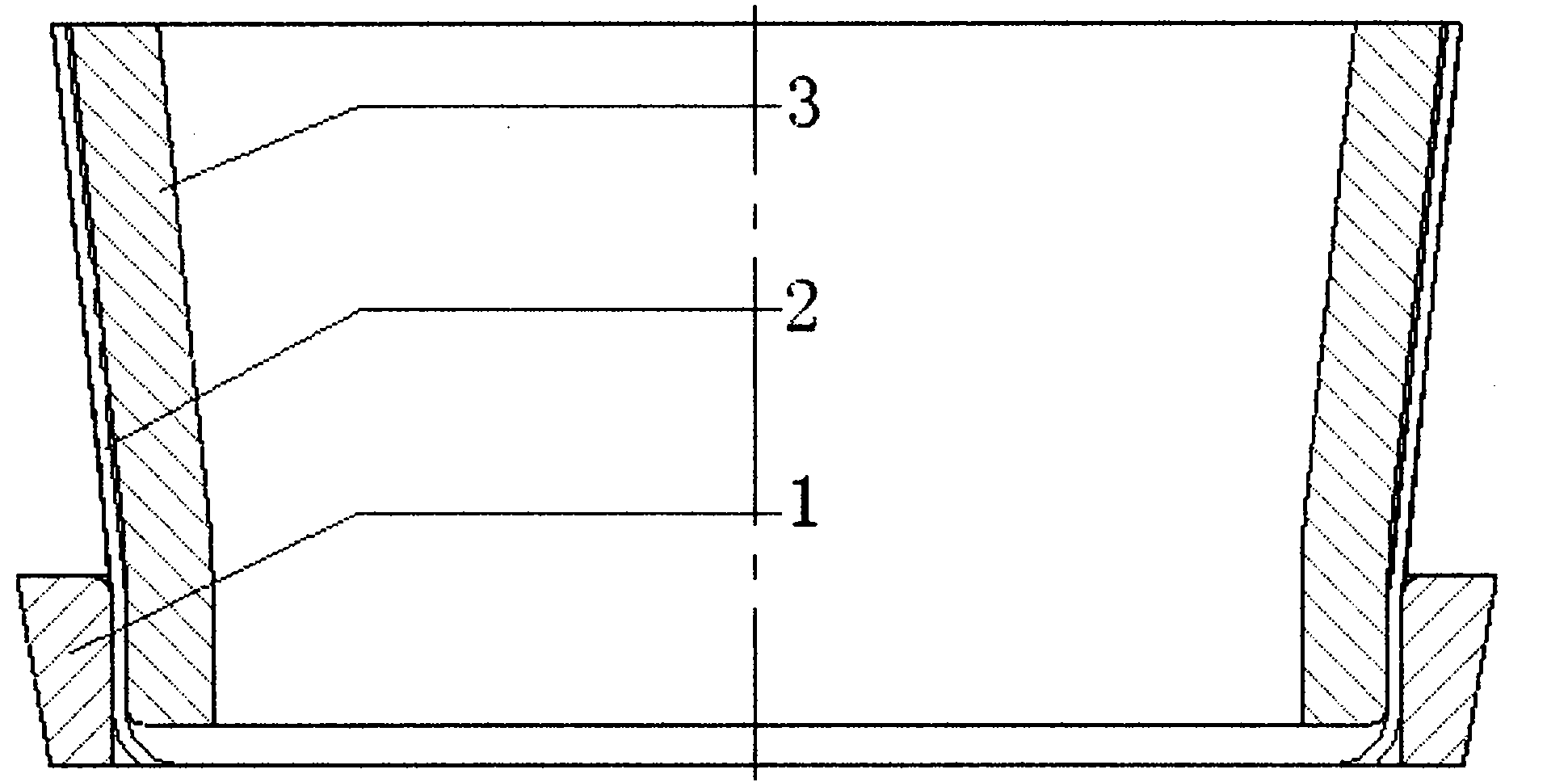

[0036] A self-gravity thermoforming process for titanium alloy thin-walled cylindrical parts: using thermoforming fixtures (such as figure 2 )'s self-weight acts on titanium alloy thin-walled cylindrical parts (see Figure 3-6 and figure 1 ) to generate pressure instead of power, and complete the hot forming of titanium alloy thin-walled cylindrical parts in a vacuum furnace.

[0037] The self-gravity thermoforming process of titanium alloy thin-walled cylindrical parts described in this embodiment also includes the following content: in the self-gravity thermoforming process of titanium alloy thin-walled cylindrical parts, the size of the mold used meets the following specific requirements: D = Φ ( ( 1 - α 1 · ΔT ) × ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com