Method for cutting wafers

A technology of wafers and blades, which is applied in the field of new technology that can improve the cutting quality of quartz wafers. It can solve the problems of affecting processing efficiency, affecting surface quality, and increasing pre-cutting time, so as to reduce the time of grinding and finishing, and reduce the breakage of knives. probability, the effect of reducing thickness dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

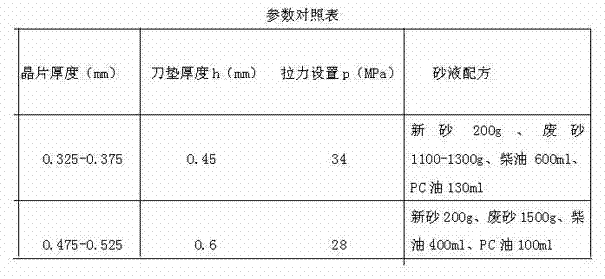

[0012] Referring to the comparison table of some parameters, the present invention mainly relates to a new process for improving the cutting quality of wafers.

[0013] 1. According to the requirements of the thickness of the wafer to be processed, select the thickness of the shim to start the knife. The thickness of the shim is 0.04-0.06mm larger than the thickness of the wafer to be processed. Measure the perpendicularity between the blade and the shim until it is smooth So far, use a vernier caliper to measure the width between the blades on both sides. When the difference between the two sides is 0.03±0.005mm, the whole knife is over. Then start to pressurize the blade to make it stretch straight. According to the thickness of the wafer to be processed, select different tension values. The range of tension value is from 24-40MPa. larger value. Based on the processing of wafers with a thickness of 0.325-0.375mm as the standard, the thickness of the knife shim is 0.4mm, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com