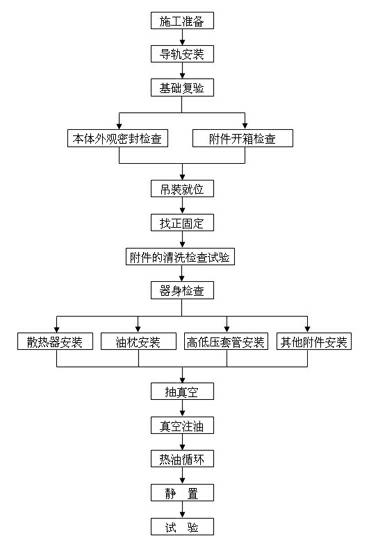

Construction process for installing and debugging large transformer

A construction technology and transformer technology, applied in the direction of inductance/transformer/magnet manufacturing, electrical components, circuits, etc., can solve the problems of long construction time, low efficiency, large randomness, etc., to ensure construction quality and safety, and reasonable process specifications , Improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] 1. Construction preparation:

[0017] The technicians prepare the construction and acceptance specifications, national standards, transformer installation process manual, transformer manufacturer's manual, factory test report, construction drawings, etc. of the corresponding electrical device installation project. Construction personnel must first be familiar with the installation drawings and product installation instructions, and organize construction personnel to conduct training and study according to the factory technical data and installation requirements in technical documents, and make safety and technical disclosures. Allocate sufficient personnel according to the size of the project, specify the person in charge of construction and the person in charge of full-time safety and quality, and make a good division of labor, and assign it to a person, and a special person is responsible. The required tools, equipment, instruments, materials and temporary safety faci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com