Method for soldering through-hole reflow device and printed circuit board

A soldering method and reflow soldering technology, applied in the direction of assembling printed circuits, electrical components, electrical components, etc. with electrical components, can solve the problems of increasing operating hours, difficult to achieve the consistency of tin amount, and increasing the manufacturing cost of THR devices. The effect of simplifying operating procedures, reducing manufacturing costs, and reducing operating hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

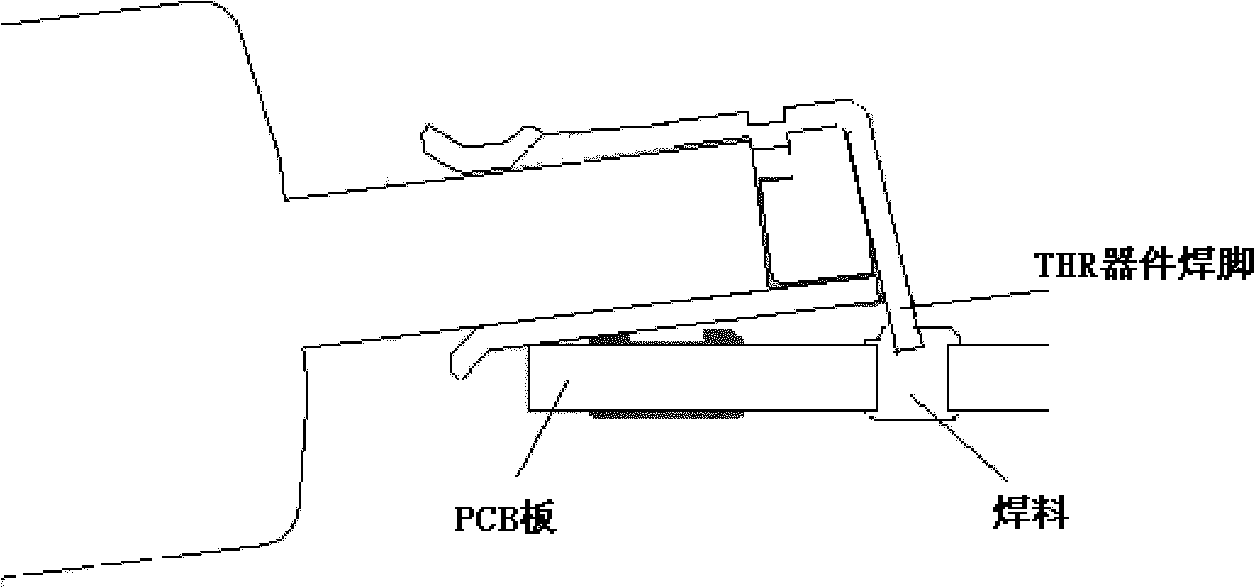

[0029] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] In view of this, the object of the present invention is to provide a soldering method and printed circuit board for through-hole reflow devices, which can effectively improve the soldering strength of THR devices without increasing the process, and can effectively control the soldering tin volume consistency.

[0031] refer to Figure 4 , is a flowchart of a soldering method for through-hole reflow devices according to an embodiment of the present invention. like Figure 4 As shown, the method described in the embodiment of the present invention includes the following steps:

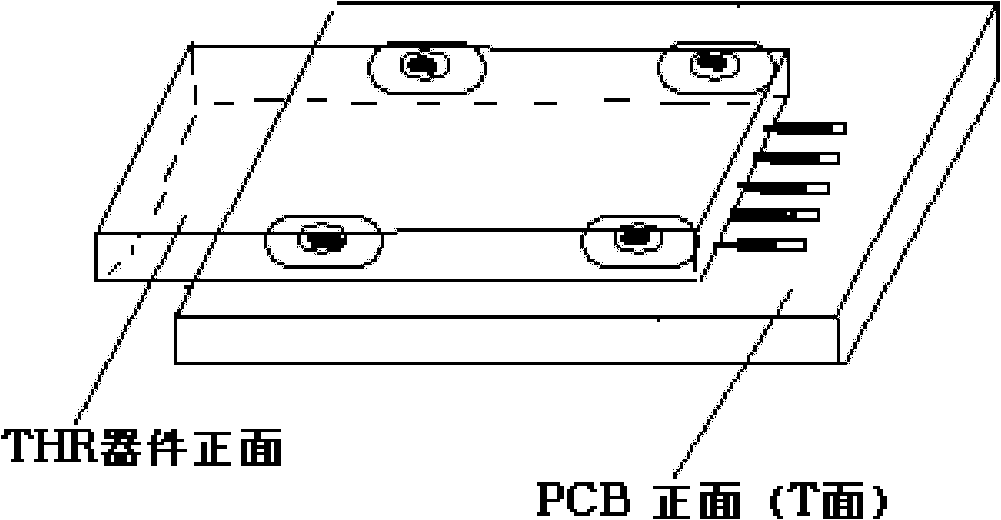

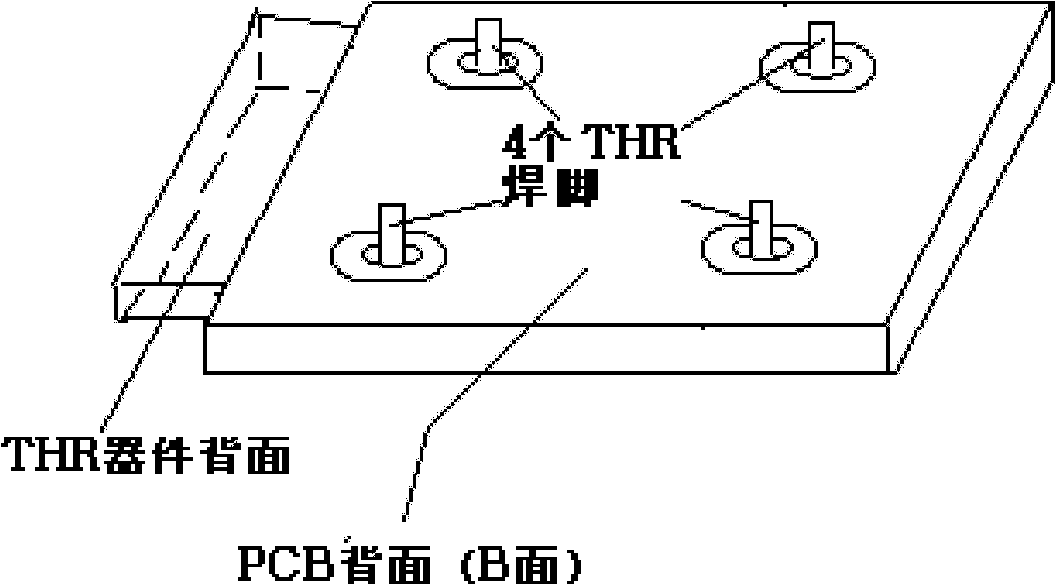

[0032] Step S11: when performing the SMT process on the B side of the PCB board, automatically print a certain amount of solder paste for each sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com