Mechanized grinding, spreading and forming machine of meat paste wrappers

A forming machine and rolling technology, which is applied in the fields of meat processing, slaughtering, food science, etc., can solve the problems hindering the production and development of swallow skin, and achieve the effect of simple structure, low manufacturing cost and less land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

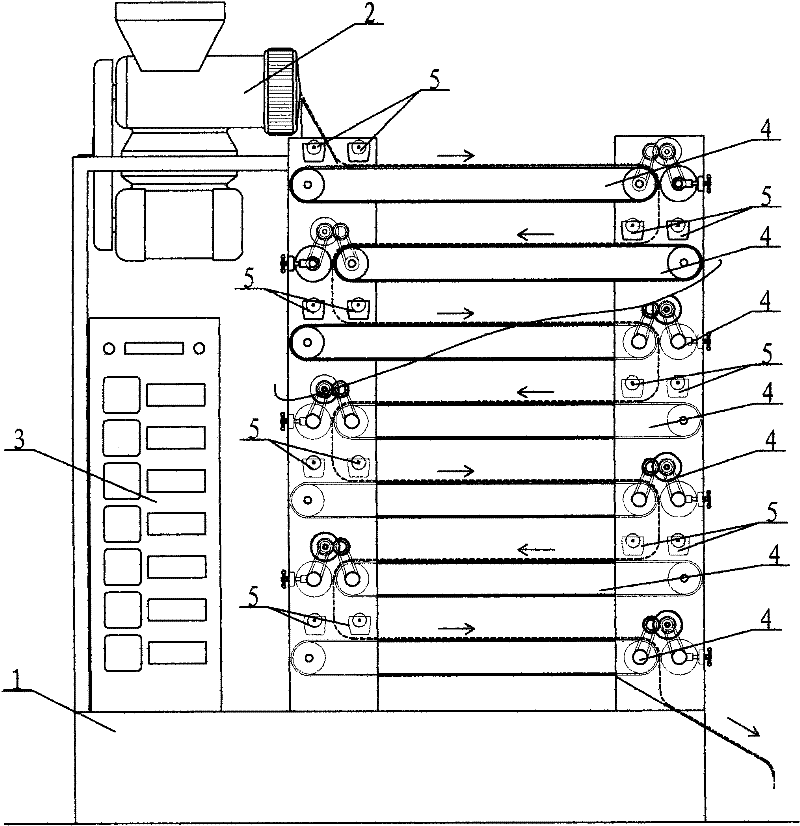

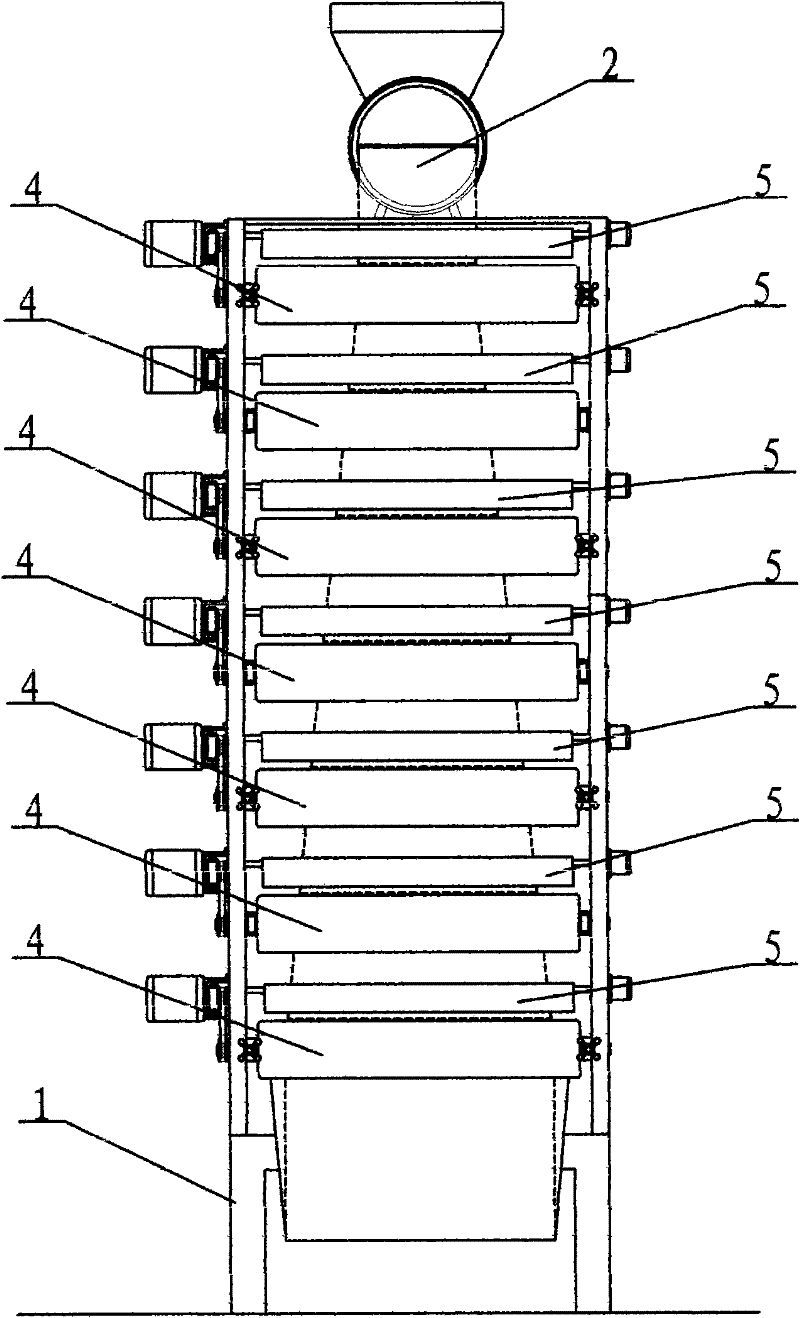

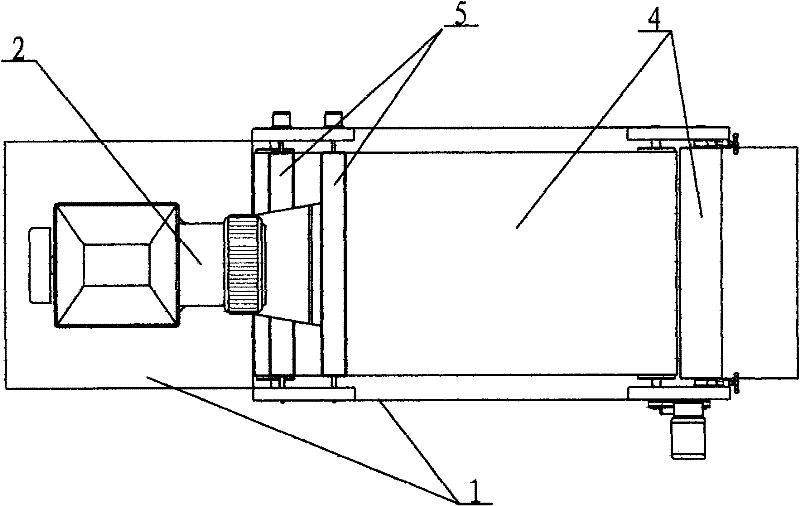

[0019] Embodiment: Referring to the accompanying drawings, as shown in the figure, the meat swallow skin mechanized rolling and forming machine mainly consists of a frame 1, a dough extruder 2, an electric control cabinet 3, a flour milling platform 4, and a vibrating sieve powder cylinder 5 Composition; Frame 1 is made of stainless steel as a whole, with a base on the lower side, a frame on the left side of the base, and a side stand on the right side consisting of four bracket plates standing side by side in a rectangular arrangement. The length of the relative rectangle is about 1.2 meters or longer, about 0.6 meters or wider in width, and the height of the side support meets the installation dimensions of the 7-way rolling and conveying table 4.

[0020] The extrusion port of the noodle extruder 2 is set on the left frame of the frame 1 facing right. The power equipment of the noodle extruder 2 is an adjustable-speed servo motor, and other adjustable-speed servo motors can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com