Method for preparing air exhaust and suction sol with smell of cigarette

An aerosol and smoke-flavored technology, which is applied in the fields of tobacco, tobacco treatment, application, etc., can solve the problems of property life threat, harmful health, etc., and achieve the effect of reducing potential danger, reducing the amount of smoking, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

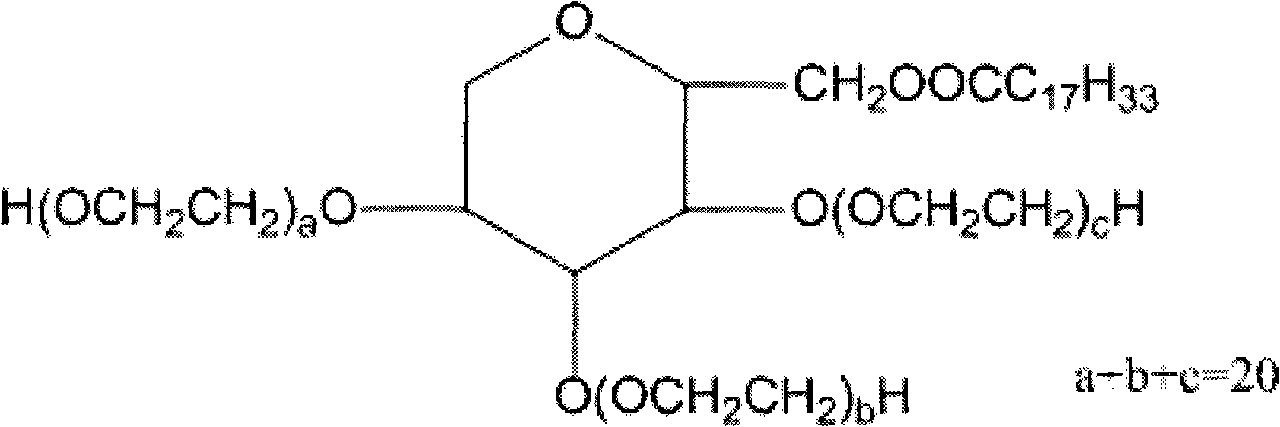

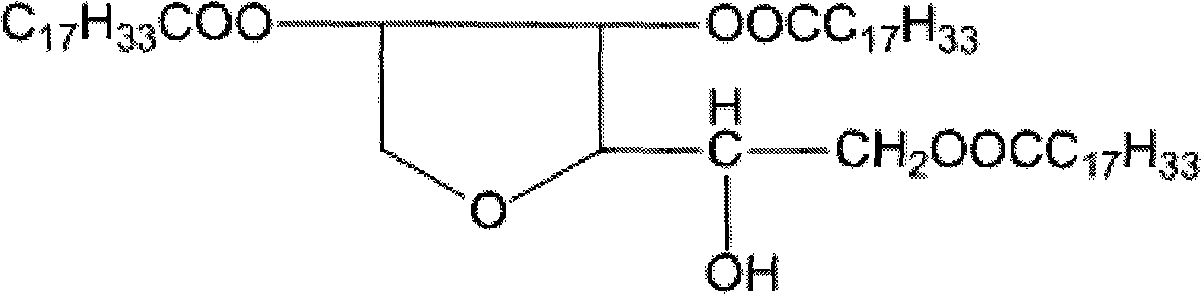

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Select the finished cigarette and let it smoke in a smoking machine to simulate the human smoking process. During the smoking process, the temperature is controlled to be 22-28° C., and the air pressure is about 1 atmospheric pressure. The flue gas produced by the smoking machine is sent to the Cambridge Filter through the flue gas channel to filter and collect tar. Elute the Cambridge filter with distilled water by ultrasonic vibration, add a small amount of surfactant to help dissolve, and prepare a tar solution with a concentration of 0.1-1%. Mix tar solution with solvent, auxiliary agent and flavoring agent to form a mixed solution. After aseptic treatment, the mixed solution is divided into suitable pressure-resistant containers (glass bottles or plastic bottles), and the propellant is filled through the valve of the container to obtain the product. The formula of this embodiment:

[0027] Material weight ratio

[0028] tar solution 5

[0029] Sol...

Embodiment 2

[0033] Embodiment 2: Select finished cigarettes and let them be smoked in a smoking machine simulating the human smoking process. During the smoking process, the temperature is controlled at 2228° C. and the air pressure is about 1 atmospheric pressure. The flue gas produced by the smoking machine is sent to the Cambridge Filter through the flue gas channel to filter and collect tar. Elute the Cambridge filter with distilled water by ultrasonic vibration, add a small amount of surfactant to help dissolve, and prepare a tar solution with a concentration of 0.1-1%. Mix tar solution with solvent, auxiliary agent and flavoring agent to form a mixed solution. After aseptic treatment, the mixed solution is dispensed into appropriate pressure-resistant containers (glass or plastic bottles). The quantitative valve body is packaged, and the propellant is filled through the valve body. Example formulation:

[0034] Material Weight ratio parts

[0035] tar solution 15

[0036] Solve...

Embodiment 3

[0040] Embodiment 3: Select finished cigarettes and let them smoke in a smoking machine to simulate the human smoking process. During the smoking process, the temperature is controlled at 22-28° C., and the air pressure is about 1 atmospheric pressure. The flue gas produced by the smoking machine is sent to the Cambridge Filter through the flue gas channel to filter and collect tar. Elute the Cambridge filter with distilled water by ultrasonic vibration, add a small amount of surfactant to help dissolve, and prepare a tar solution with a concentration of 0.1-1%. Mix tar solution with solvent, auxiliary agent and flavoring agent to form a mixed solution. After aseptic treatment, the mixed solution is dispensed into appropriate pressure-resistant containers (glass or plastic bottles). The quantitative valve body is packaged, and the propellant is filled through the valve body. Example formulation:

[0041] Material Weight ratio parts

[0042] Tar solution 25

[0043] Solven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com