Active matrix substrate and manufacturing method thereof

An active matrix and substrate technology, applied in the field of optical sensor structure and its manufacturing, can solve the problems of low detection sensitivity of optical sensors and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

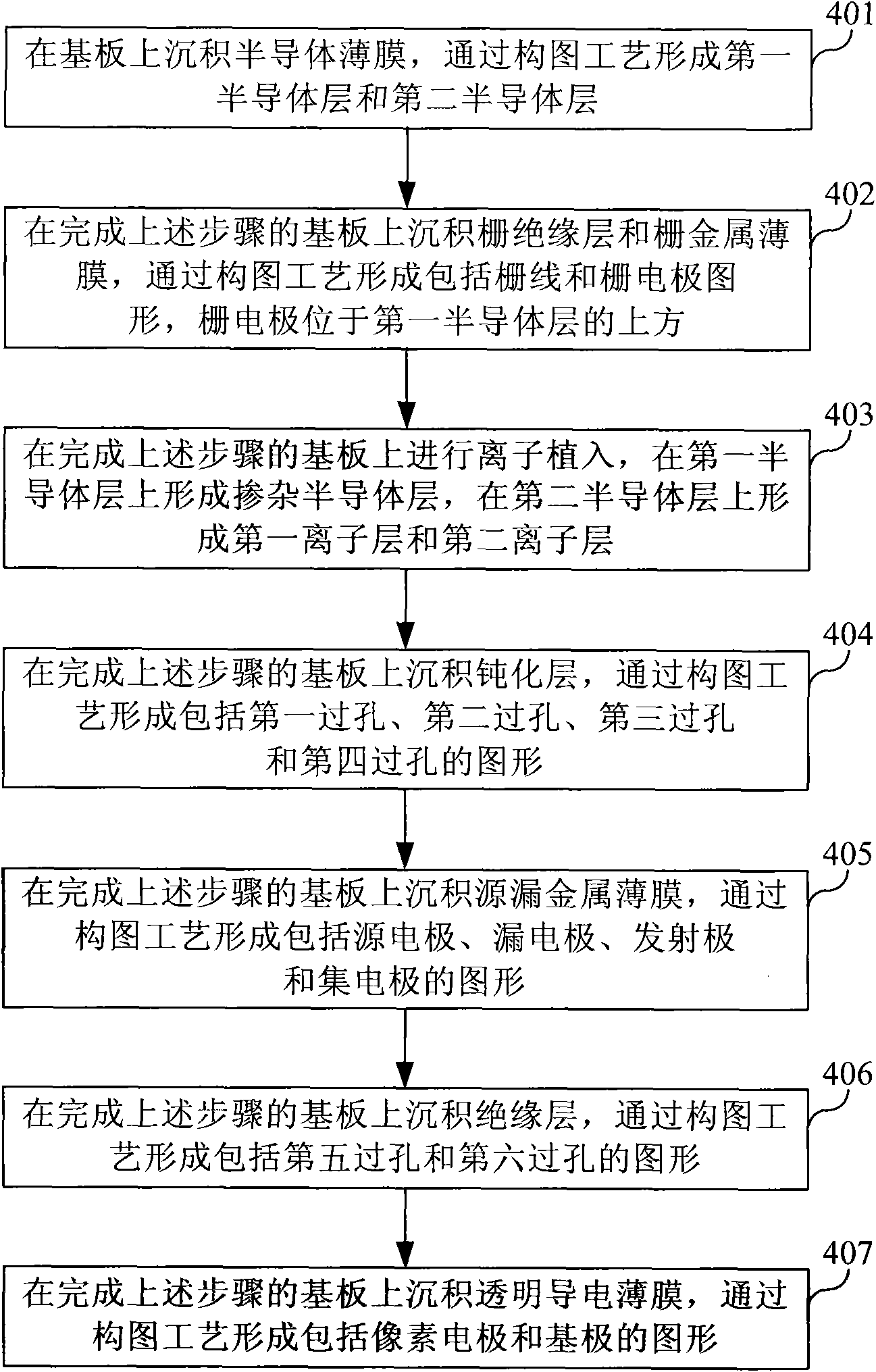

[0056] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

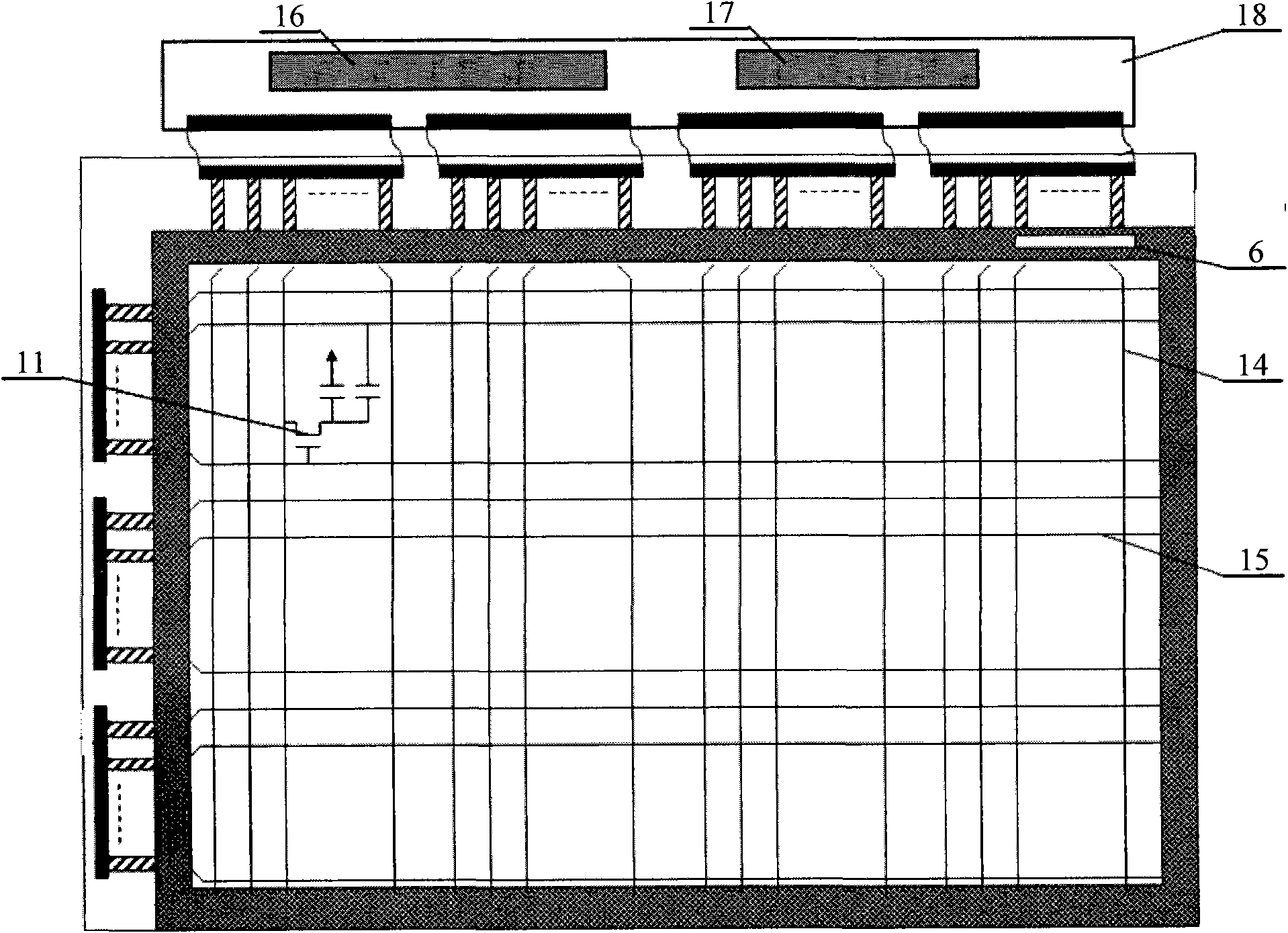

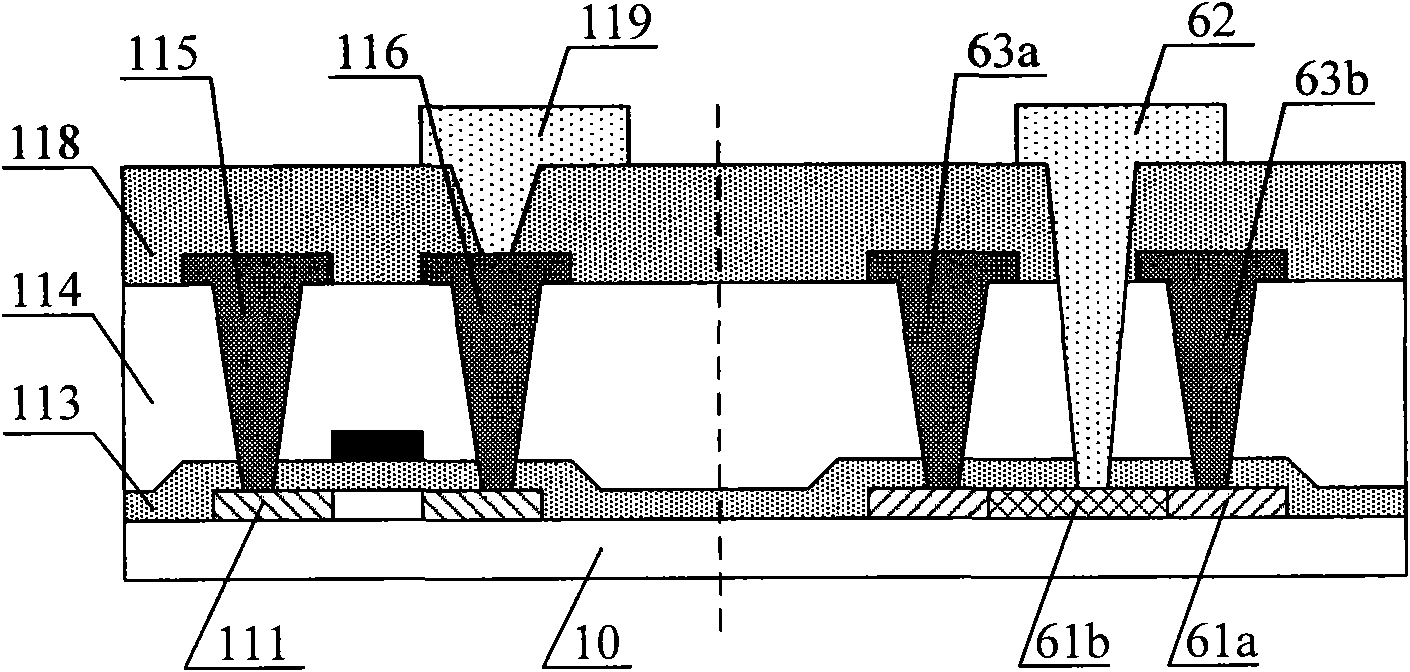

[0057] figure 1 It is a structural schematic diagram of the active matrix substrate of the liquid crystal display device of the present invention. Such as figure 1 As shown, in the display area on the active matrix substrate, vertical lines (data lines) 14 and horizontal lines (gate lines) 15 are arranged vertically and intersecting each other. The gate lines 15 and data lines 14 define each pixel area, and form pixel electrodes in the pixel area. and a thin film transistor (TFT) 11 . A photosensor 6 having a triode structure is formed on the substrate. The peripheral circuits on the active matrix substrate are connected to the external circuit board 18 through a flexible printed circuit (FPC). The external circuit board 18 has a first circuit 16 that provides drive control signals for the data line 14 and the gate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com