Superconducting motor with torque tubes

A technology of superconducting motors and torque tubes, applied to electrical components, electromechanical devices, etc., can solve the problems of increasing the volume and weight of motors, and achieve the effects of compact structure, reduced heat leakage, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

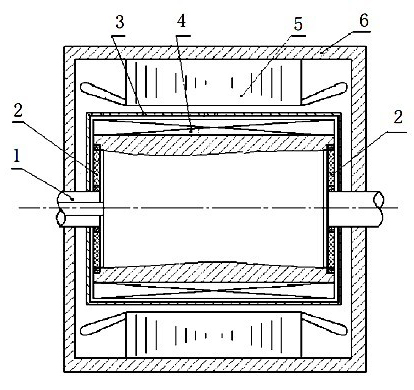

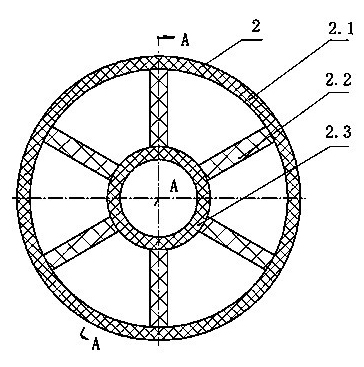

[0021] Example 1: Such as figure 1 , 2 Shown in , 3, be the superconducting motor that has torque tube of the present invention, it has a rotating shaft 1, torque tube 2, stator 5 and motor casing 6; Described torque tube 2 has two, is respectively fixed on two sides of rotating shaft 1 end, located in the vacuum Dewar vessel 3; the torque tube 2 is a flat ring, including the outer ring 2.1 and the inner ring 2.3 and the support 2.2 connecting the outer ring 2.1 and the inner ring 2.3; the outer ring 2.1 and the superconducting The end face of the magnet system 4 is fixedly connected; the inner ring 2.3 is fixedly connected to the rotating shaft 1 at normal temperature; the support member 2.2 is a support rib, or selected as a support plate; the material forming the torque tube 2 is at least the support member 2.2. . The outer ring 2.1 of the torque tube 2 is fixedly connected to the end face of the superconducting magnet system 4 through a connection key, or an interferen...

Embodiment 2

[0022] Example 2: The difference from the above-mentioned embodiments is that the heat insulating material used for the moment tube 2 of the integral component is an epoxy board or hard plastic that does not crack at 20K, does not become brittle, has high strength, and has good heat insulation performance.

Embodiment 3

[0023] Example 3: The difference from the above embodiment is that the heat insulating material used in the moment tube 2 of the integral component is not cracked or brittle under 20K, has high strength and good heat insulation performance, and is used for weaving and forming fiber materials and after forming. For impregnated low-temperature glue, the low-temperature glue is selected from DW3, JSF-6, ABS resin epoxy glue or epoxy resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com