Oil sucking machine with small torque and low energy consumption

A low energy consumption, pumping unit technology, applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc., to achieve good stability, reduce driving power, and facilitate popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

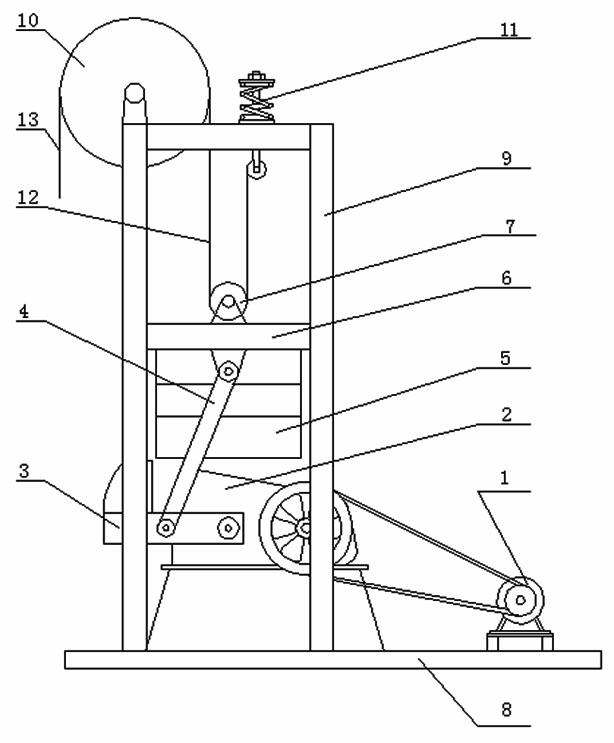

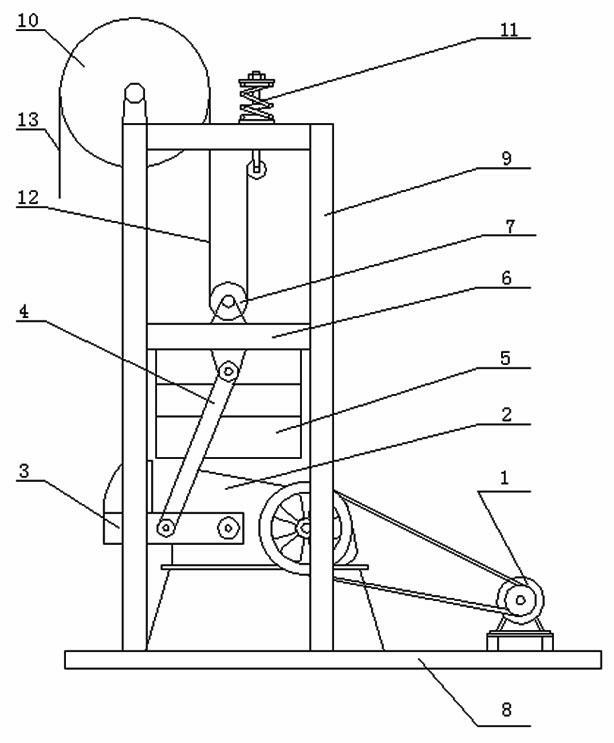

[0013] The present invention will be further described below in conjunction with accompanying drawing:

[0014] As shown in the accompanying drawings, the low-torque and low-energy pumping unit includes a motor 1, a reducer 2, a crank 3, a connecting rod 4, a counterweight 5, a pulley 6, a movable pulley 7, a base 8, a bracket 9, a fixed pulley 10 and Buffer 11. The support 9 is fixed on the base 8, and there are slideways in the four corners of the support 9, and the fixed pulley 10 is connected to the top side of the support 9 through a bearing seat. There are multiple grooves on the fixed pulley 10, and the fixed pulley 10 grooves are respectively wound Lifting chain 12 and lifting chain 13 are arranged, or steel wire rope is used to replace lifting chain 12 and lifting chain 13, one end of lifting chain 13 is fixed on the fixed pulley 10, and the other end of lifting chain 13 is connected with the polished rod through a rope hanger. One end of the bit chain 12 is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com