Parallel flow air conditioner and processing method thereof

An air conditioner and parallel flow technology, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of low heat exchange efficiency, uneven distribution, high cost, etc., and achieve improved heating efficiency, uniform distribution, and improved The effect of heating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

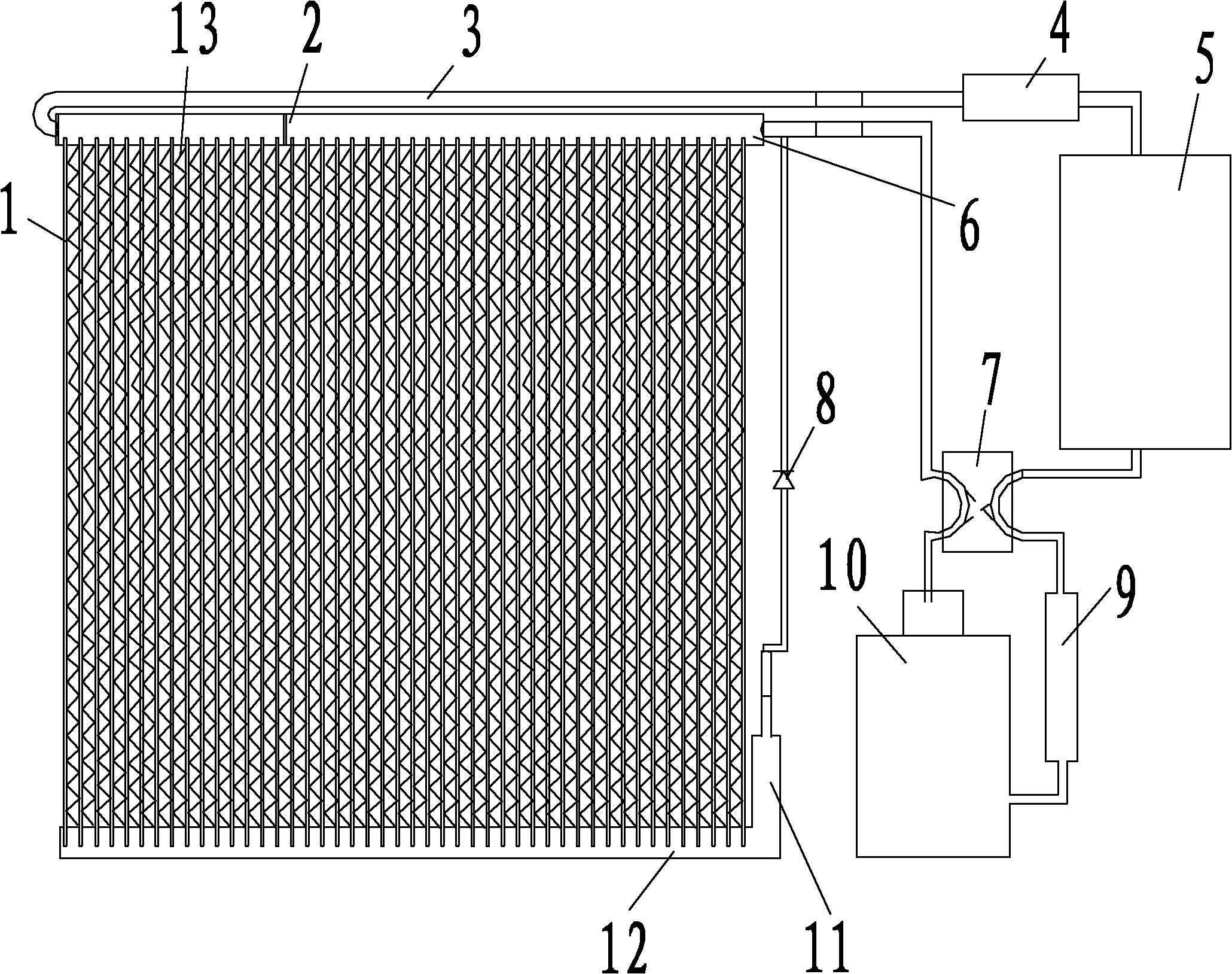

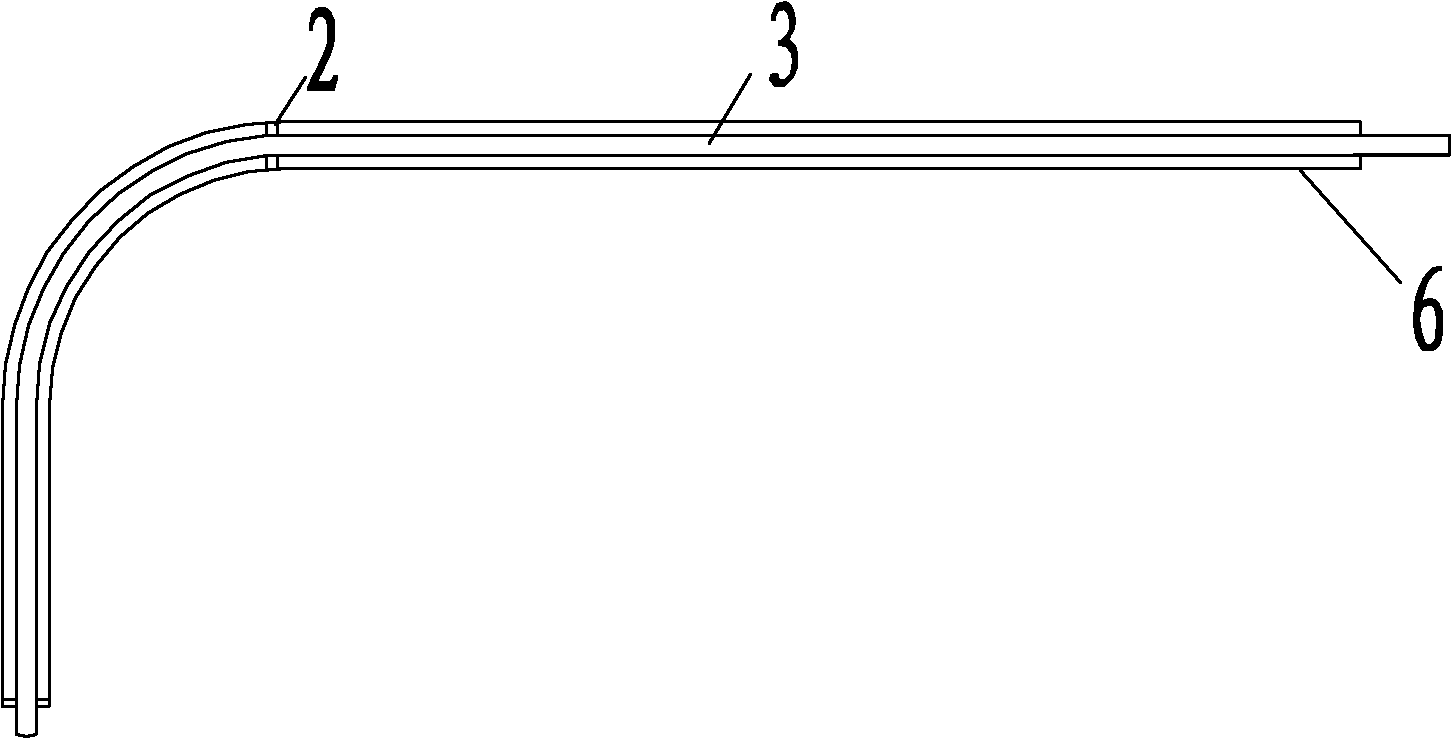

[0031] Such as figure 1 The 2-process parallel flow cooling and heating air conditioner shown includes compressor, compressor return air pipe, four-way valve, indoor unit, capillary assembly, upper end pipe of upper liquid collection pipe, upper liquid collection pipe, flat heat exchange pipe and lower liquid collection pipe tube, such as figure 2 As shown, the upper liquid collection pipe and the lower liquid collection pipe are in the shape of an arc curved "L" in the top view, the compressor and the compressor air return pipe are respectively connected to the two connection ports of the four-way valve, the indoor unit, the upper The first end of the liquid collection pipe is respectively connected to the other two connection ports of the four-way valve. The indoor unit is connected to the upper pipe of the upper liquid collection pipe through the capillary assembly. There is a partition inside, and the position of the partition is about 1 / 3 of the length of the upper liqu...

Embodiment 2

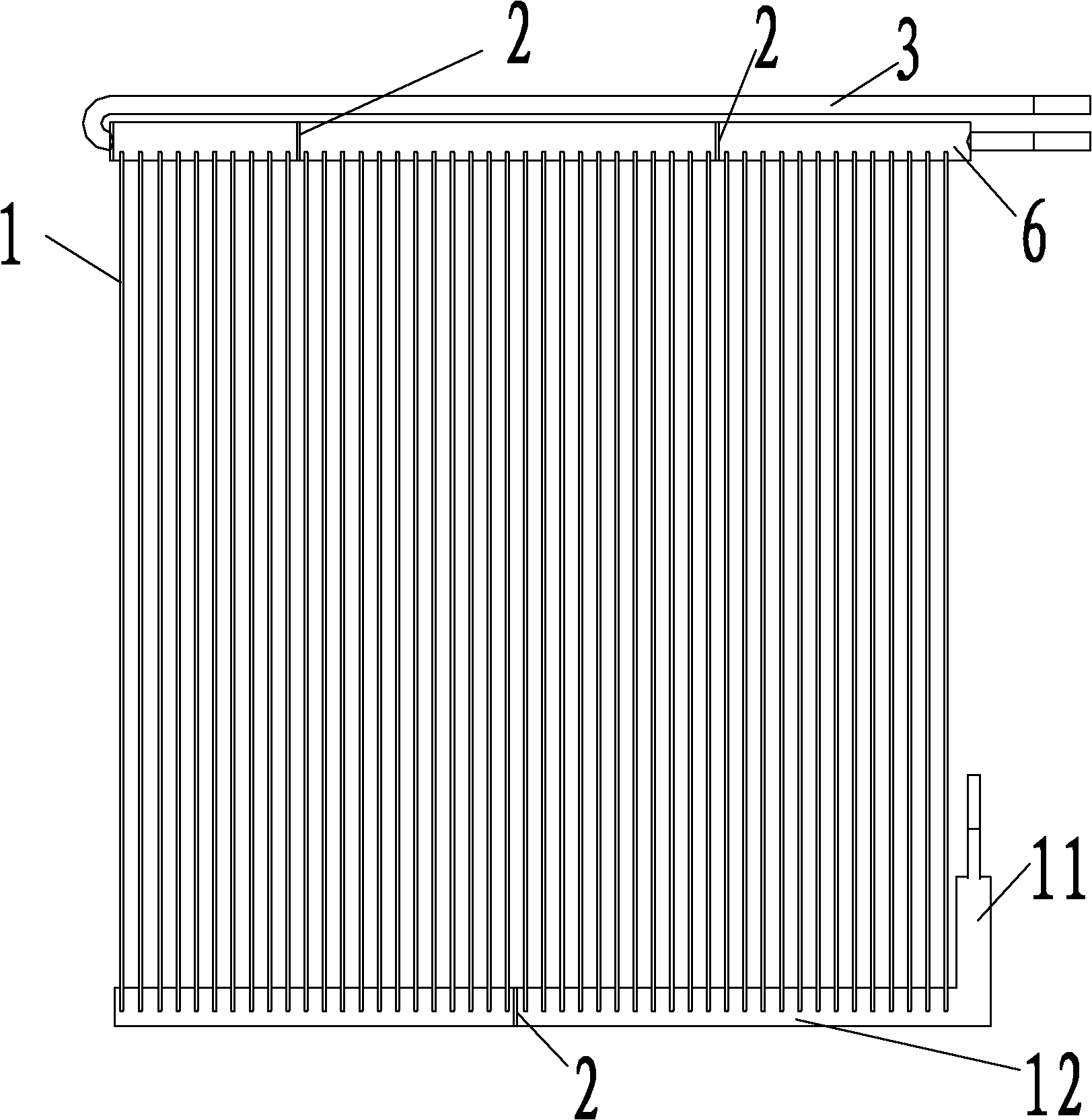

[0040] Such as image 3 As shown, there are two partitions inside the upper liquid collecting pipe, and one partition inside the lower liquid collecting pipe. The parallel flow heating and cooling air conditioner has 4 processes. The positions of the partitions are shown in the figure. The heat pipe is a process, the flat heat exchange tube between the upper left baffle and the lower baffle is a process, the flat heat exchange tube between the lower baffle and the upper right baffle is a process, and the one on the right side of the upper right baffle is a process. The flat heat exchange tube is a process.

[0041] The working principle of the 4-process parallel flow heating and cooling air conditioner is basically the same as that of the 2-process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com